Power-to-X: cornerstone for decarbonisation and economic resilience of the chemical industry

The chemical industry in the ARRRA cluster (Antwerp, Rotterdam, Rhine and Ruhr area) is under severe pressure due to high energy prices and increasingly stringent climate targets. Plants are closing and jobs are being lost. Yet this moment also presents an opportunity for renewal. By investing in Power-to-X technologies alongside biobased routes, the cluster can strengthen its international competitiveness and secure its long-term future. This is the key message of the new whitepaper Harnessing Power-to-X for a Sustainable Carbon Future by TNO and VoltaChem.

Download the whitepaper

Discover the strategic directions for the ARRRA cluster and how TNO supports companies with techno-economic analyses and roadmaps for decarbonisation in the whitepaper 'Harnessing Power-to-X for a Sustainable Carbon Future'.

Chemical industry under pressure, but vital for the economy

The chemical sector is of major importance to the European economy. In the Netherlands alone, the sector accounts for 2% of GDP (€87 billion). The ARRRA cluster produces 40% of Europe’s chemicals. However, the interconnection of plants and infrastructure makes the system vulnerable.

'The cluster is like a web of tightly stretched threads: if too many are pulled loose, the whole structure loses its tension and collapses,' says Monalisa Goswami, Senior Business Developer Power2Chemicals at TNO.

Power-to-X as a driver of decarbonisation and new markets

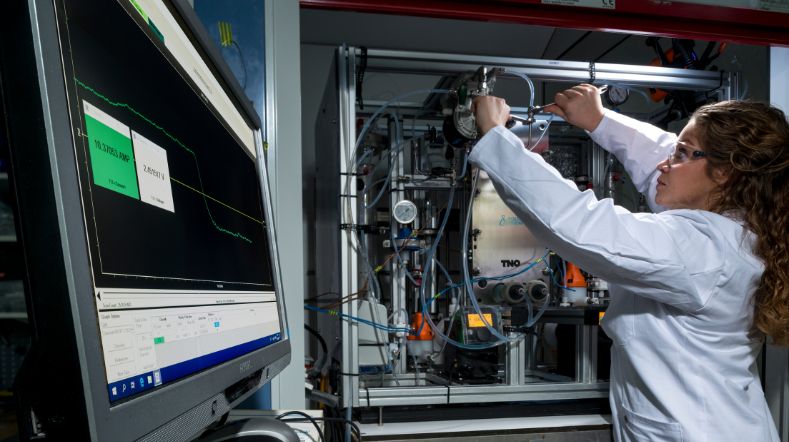

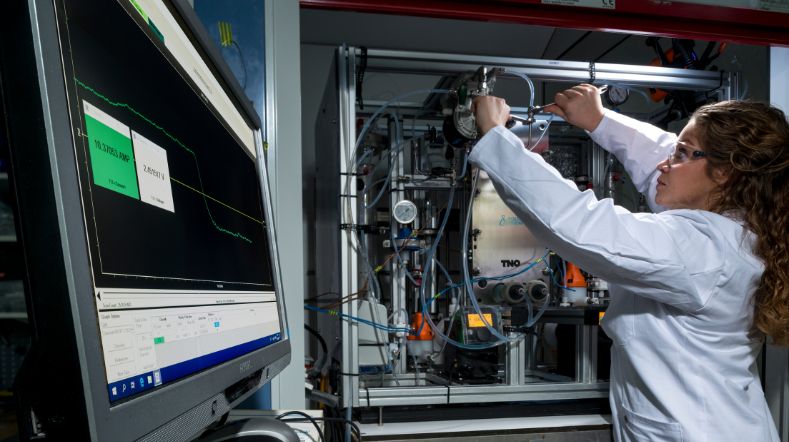

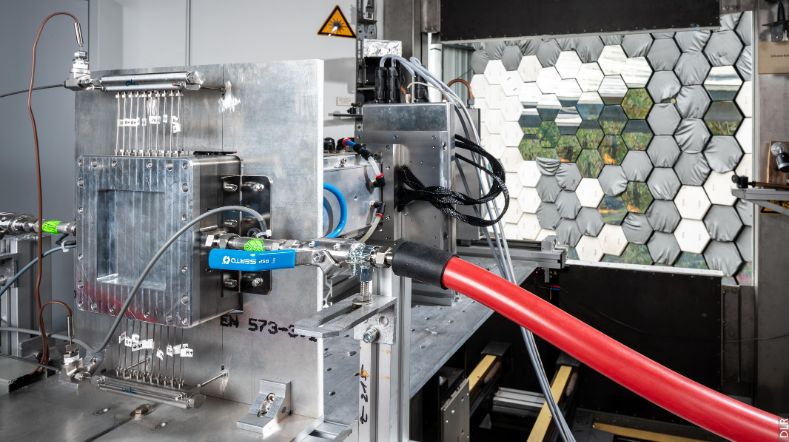

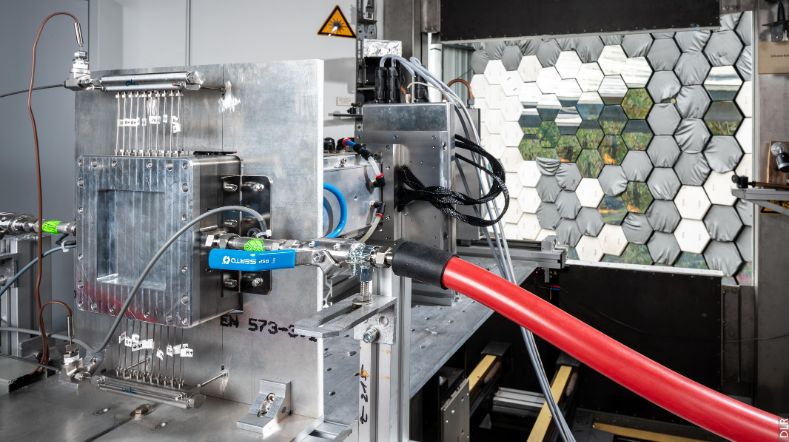

Power-to-X uses renewable electricity to produce chemical products without fossil feedstocks. In this way, CO₂ – a greenhouse gas – can be utilised as a valuable resource. Power-to-X encompasses three main routes:

- Direct electrification of chemical processes.

- green hydrogen as a feedstock or for energy.

- Carbon Capture and Utilisation (CCU): capturing CO₂ and converting it into chemicals or fuels.

Direct electrification using wind or solar power is most promising. In addition, existing chemical processes need to be further electrified by the use of green hydrogen as feedstock and renewable electrons.

Economic opportunities and challenges

The ARRRA cluster has strong assets: access to offshore wind, an integrated infrastructure and a powerful knowledge ecosystem. These create significant economic opportunities, such as access to new export markets, retention of employment and strengthened innovation capacity for companies in the region.

At the same time, challenges remain: high upfront investment costs, differences in energy prices between countries and the need to scale up technologies from the laboratory to industrial applications.

'For companies, Power-to-X is not only a decarbonisation pathway, but also a strategic business case: access to new markets aligned with European climate policy, the e-SAF mandates, for example and reduced dependence on fossil resources. All these lead to long-term structural cost advantages,' Goswami explains.

'Without swift action, the cluster will lose ground. With Power-to-X, biobased routes and recycling, we can create new business models and value right now.'

New business models and value creation

According to TNO, localised solutions are essential. 'There are no clear winners yet; the optimal mix varies by region,' Goswami emphasises. 'But one thing is clear: without swift action, the cluster will lose ground. With Power-to-X, biobased routes and recycling, we can create new business models and value right now.'

Strategic directions for the ARRRA cluster

The whitepaper identifies two strategic directions to secure the cluster’s future: investment in strategic production capacity for sustainable chemicals and fuels such as e-SAF (synthetic aviation fuel), and the development of a leading role as an international licensor. Together, these strategies offer both decarbonization solutions and new economic value creation.

Get inspired

Gasifying waste and residual wood for large scale Green Gas production

Turning CO2 into formic acid for sustainable energy and chemical applications

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale