Printing from potatoes: How Royal Avebe and TNO are working towards the future of food

Food security is a hot topic for food producers. Originally a potato starch specialist, Royal Avebe sees the shift to more plant-based protein products as a strategic opportunity. By working with TNO, the company got involved early on in innovative solutions that could fundamentally change the way we produce food. Find out how this collaboration can transform the future of food.

Shaping the future

Together with TNO, Wageningen University & Research, and other organisations, Avebe is working to produce plant-based meat substitutes in a promising way: by using 3D food printers. Annet Vrieling is a food application specialist at Avebe. ‘We want to shape the future of food, both literally and figuratively.’

‘We wanted to discover what else we could achieve with our resources,’ she explains. ‘Our potato starch offers unique properties that would be a perfect fit for new food applications. Starch potatoes are high in starch, protein, and fibre and can be processed in different ways. So, it can remain nice and liquid, or be firm and jelly-like.’

New food varieties

3D printing technology has the potential to revolutionise the food industry. Whereas traditional meat substitutes are often limited in texture and form, 3D printing offers entirely new prospects. It could be used to accurately print fish structures that were previously difficult to reproduce or create completely new food varieties that are different from what we are used to.

‘We want to develop the expertise to make products that are not only technically sound, but also tasty and appealing to consumers,’ says Vrieling. ‘TNO’s technology enables us to design food that is both visually appealing and appetising, and allows us to push the boundaries of what is possible in food production.’

‘We want to develop the expertise to make products that are not only technically sound, but also tasty and appealing to consumers. TNO’s technology enables us to design food that is both visually appealing and appetising, and allows us to push the boundaries of what is possible in food production.'

Accelerating innovation together

Vrieling continues, ‘By pooling our expertise, we can accelerate innovation. Avebe brings the ingredient knowledge, TNO brings the technology, and Wageningen University brings the scientific knowledge and analysis. Transforming the food production chain is simply too big to tackle alone. There are all kinds of steps in this process: from changing the structure of proteins to the composition and behaviour of the paste that goes into the printer. And also, how does it work in the printer? Is it technically scalable? Is it fast enough? When you eat the product, how does it feel in the mouth? Is it firm enough, or too firm? If something isn’t right, we have to go back to the drawing board. Every single aspect is important, so there really is a lot involved. That is why we are working on this together.’

Early involvement in new innovations

Vrieling stresses the importance of getting involved in innovations at an early stage. ‘It’s crucial to constantly explore new things, what direction they are heading in, and how our company can respond to them. That’s why collaborating with high-tech partners such as TNO and Wageningen University & Research is so important. They bring the latest ideas and innovations, and we can then add our perspective and anticipate changes. If we wait until something is on the market to look at what our ingredients can contribute, then it is simply too late.’

Sustainable ambition

Underpinning the collaboration is a clear social ambition. With a growing global population, the need for alternative protein sources is becoming increasingly urgent. Plant-based alternatives can play a vital role in reducing the carbon footprint of our food systems. ‘It’s not about replacing meat completely,’ Annet Vrieling stresses, ‘but about offering high-quality alternatives. Consumers should be able to choose products that are both sustainable and delicious.’

'It’s crucial to constantly explore new things, what direction they are heading in, and how our company can respond to them. That’s why collaborating with high-tech partners such as TNO and Wageningen University & Research is so important.'

Next steps

The technology is universally applicable and can be adapted to local preferences. ‘Food security is a global challenge,’ argues Vrieling. ‘This innovation can make an impact anywhere in the world.’

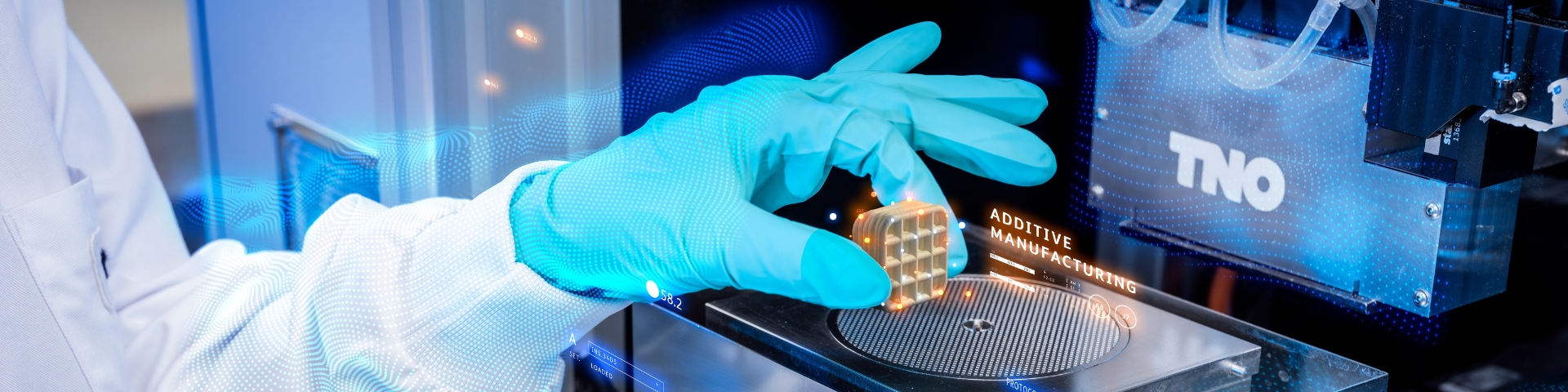

That future is getting closer with the new prototype 3D printer developed by TNO. This printer can achieve the high production speeds we need. Plus, the new design is quicker to clean and maintain, making production more efficient. This means the printer is scalable. The next step is for a company to test it out in a factory.

Read more

See TNO's impact on the protein transition via the link below.

Get inspired

3D pharma printing: Personalised medicine begins here

3D food printing: is this the future of our food?

3D printed food: the future of personalised nutrition

TNO research lays foundation for more reliable allergen information on food labels

TNO launches digital health spin-off AIKON Health for wearable monitoring