Turning CO2 into formic acid for sustainable energy and chemical applications

As the world seeks solutions to reduce carbon emissions and transition toward a sustainable and cost efficient chemical industry, efficient utilization of CO₂ has become a major challenge. In response, TNO is coordinating the eCO2FORM project, bringing together five partners to develop the electrochemical conversion of CO₂ into formic acid.

Downstream applications

The project not only focuses on formic acid production but also explores novel downstream applications, including its use as a hydrogen carrier and as a feedstock for sustainable aviation fuels (SAF). This four-year project is funded through the RVO MOOI program.

According to project manager Erwin Giling (TNO): 'Formic acid is the simplest molecule that can be produced from CO₂ electrochemically, and it has already been the focus of research at TNO and other organizations. However, significant development is still needed to bring this technology to a higher TRL level.'

'New downstream routes using formic acid or formate as a platform molecule could unlock entirely new markets.'

Novel downstream routes via formic acid

The electrochemical conversion of CO₂ to formic acid requires relatively low electricity input at low temperatures, making it a promising route for CO₂ valorization. Current industrial markets for formic acid are modest, including applications as a preservative, in leather tanning, pharmaceuticals, and chemical intermediates.

Monalisa Goswami (TNO, Senior Business Developer) explains: 'New downstream routes using formic acid or formate as a platform molecule could unlock entirely new markets.

Hydrogen storage and sustainable aviation fuels are two promising avenues being developed in this project. These applications could make the business case for electrochemical CO₂ conversion much more attractive.'

Consortium developing core technology and downstream processes

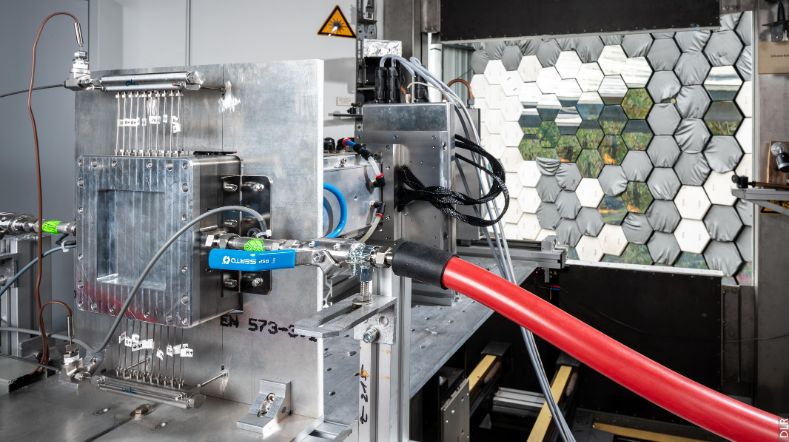

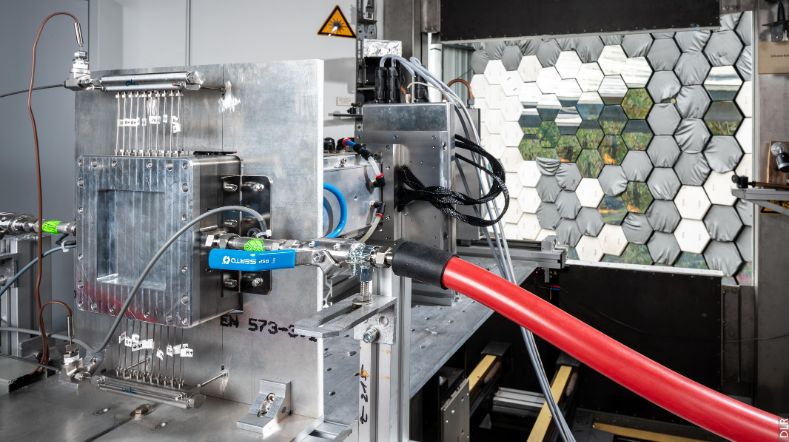

In eCO2FORM, TNO and GAFT are developing low- and high-pressure technologies to convert CO₂ into formate. Water Future is advancing the conversion of formate into formic acid using electrodialysis with bipolar membranes (ED-BPM), while the University of Twente works on low-cost, highly water-permeable bipolar membranes. GAFT will integrate high-pressure CO₂ conversion and formate processing into a pilot system.

For downstream applications, DENS is developing a dehydrogenation reactor to convert formic acid into hydrogen and electricity, potentially enabling stand-alone power systems as a battery replacement.

Another route focuses on sustainable aviation fuels, converting formate in fermentation reactors to fatty acids suitable as high-quality SAF feedstock, developed in collaboration with GAFT.

'Our goal is to develop technologies ready for industrial implementation within 10 years.'

Long-term vision

The eCO2FORM project aims to produce formic acid in 50% and 85% concentration, with 85% being the industry standard. A key challenge is to become price-competitive with fossil-based formic acid.

Erwin Giling (TNO, Project Manager) adds: 'Our goal is to develop technologies ready for industrial implementation within 10 years. To increase success, we are building a 'formic acid ecosystem' with the consortium, jointly developing promising utilization routes. Demand creation and supportive policies will also be essential to accelerate market introduction.'

Get inspired

Gasifying waste and residual wood for large scale Green Gas production

Power-to-X: cornerstone for decarbonisation and economic resilience of the chemical industry

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale