Acceleration of electrochemical CO2 conversion and development of applications via formic acid

Status project

2025-2029

In cooperation with

The Netherlands Enterprise Agency (RVO), TNO, GAFT, Waterfuture, University of Twente, and DENS

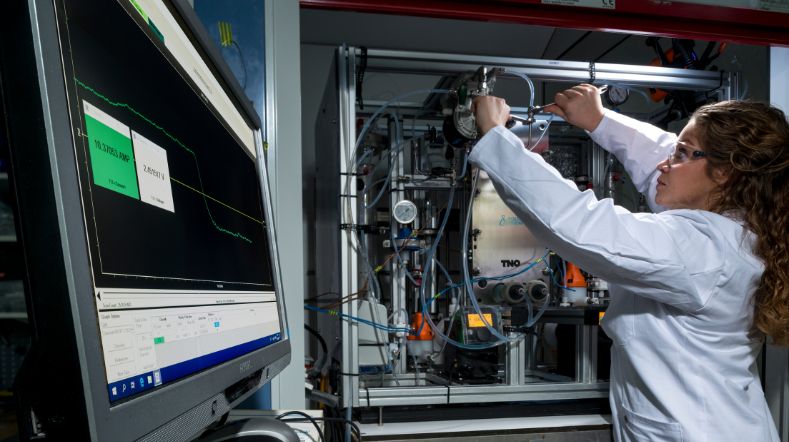

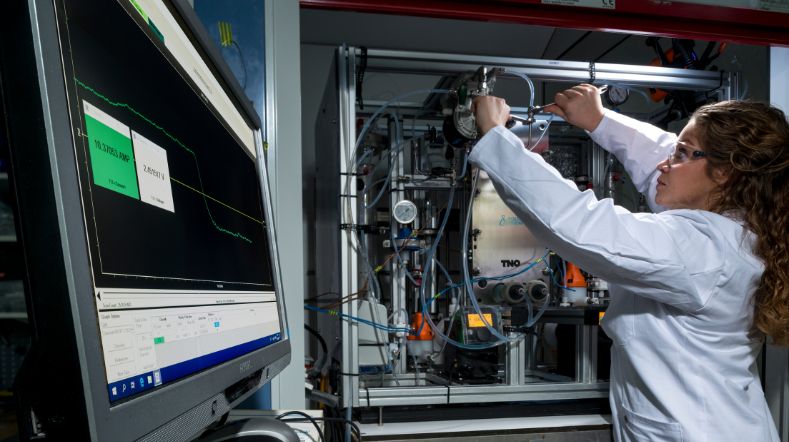

The new eCO2FORM project with a total of five project partners is coordinated by TNO and it aims to realise efficient electrochemical conversion of CO2 to formic acid. Next to that, the project will also develop novel value chains based on non-fossil formic acid. The focus is on its use as an energy and hydrogen carrier, and as feedstock for sustainable aviation fuels (SAF).

Impuls van CO2-conversie naar mierenzuur

The four-year project was recently awarded funding through the RVO MOOI scheme leading to a total project size of almost six million euros. According to project manager Erwin Giling at TNO, this four year project will bring a much needed boost to various aspects of electrochemical conversion of CO2 to formic acid.

'Since formic acid is the simplest molecule to produce using electrochemical CO2 conversion, it has already been at the focus of earlier R&D efforts within TNO and several other organisations. However, much developmental work still needs to happen to bring the core technology to a higher TRL level.'

'The new downstream conversions with formic acid or formate as a platform molecule could lead to new markets. Hydrogen carrier and Sustainable Aviation Fuel (SAF) are the two that are being developed in this project.'

Novel Downstream routes via formic acid

The relatively low electricity requirements for low temperature conversion of CO2 to formic acid holds significant potential for electrochemical CO2 valorisation. But such technologies have not yet been proven at TRL higher than 5.

According to senior business developer Monalisa Goswami, 'formic acid on its own is today has a modest market size, it is used as a preservative, for production of chemical intermediates, in leather tanning, pharmaceuticals, etc.

However, the new downstream conversions with formic acid or formate as a platform molecule could lead to new markets. Hydrogen carrier and Sustainable Aviation Fuel (SAF) are the two that are being developed in this project. This could make the business case for the electrochemical conversion of CO2 to formic acid attractive in the future.'

Consortium to develop core technology and downstream routes

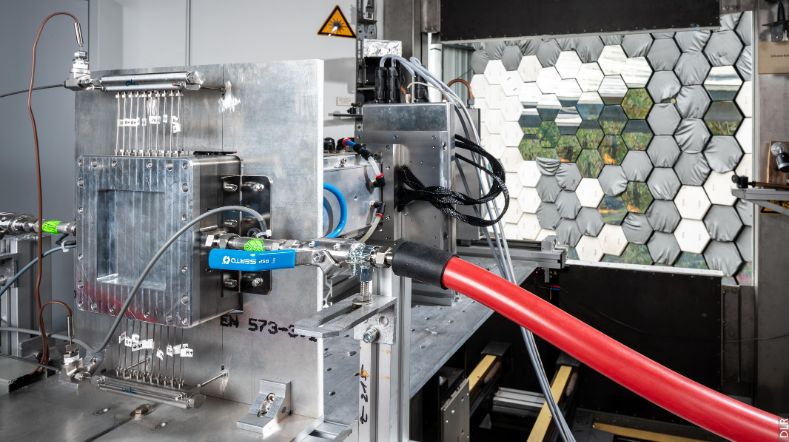

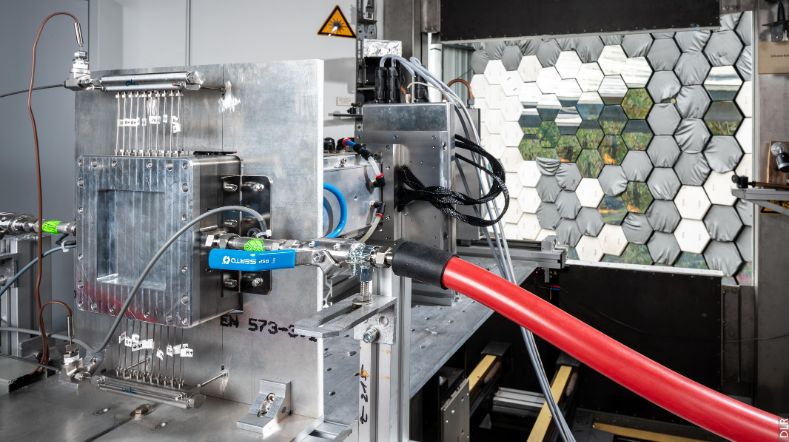

In this project TNO and GAFT are developing a low-pressure and high-pressure technology, respectively, to convert CO2 to formate. A crucial process step is the conversion of formate to formic acid. This development will be performed by Water Future using electrodialysis over bipolar membranes (ED-BPM).

The University of Twente will contribute to this, advancing new, highly water-permeable low-cost bipolar membranes. GAFT will further design and develop an integrated pilot system combining high-pressure CO2 conversion and formate processing into formic acid.

For the novel downstream routes, DENS will develop and test a dehydrogenization reactor to convert formic acid to hydrogen and electricity. Such a system could for instance feature in a stand-alone power supply unit, replacing batteries.

The other application route leads towards sustainable aviation fuels (SAF). For this, formate is processed in a fermentation reactor, yielding fatty acids that provide a high-quality feedstock for SAF synthesis. This route will be explored in cooperation with the company GAFT.

'In eCO2FORM, we now aim at developing technologies for implementation in industry within 10 years. To increase the chances of success, we build a ‘formic acid ecosystem’.'

Long-term vision

The eco2FORM project aims to produce formic acid in 50% and 85% concentration, the latter being the industry standard. The challenge will be to be price-competitive with the current fossil based formic acid in the market.

Giling: 'In eCO2FORM, we now aim at developing technologies for implementation in industry within 10 years. To increase the chances of success, we build a ‘formic acid ecosystem’ with this consortium that jointly develops the aforementioned promising utilization routes.

Several players have been working on sustainable formic acid in the last decade, and we know it will be tough to compete with fossil-based routes. As such, demand creation by supporting policies will be of importance to accelerate market introduction.'

Get inspired

Gasifying waste and residual wood for large scale Green Gas production

Turning CO2 into formic acid for sustainable energy and chemical applications

Power-to-X: cornerstone for decarbonisation and economic resilience of the chemical industry

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry