Maximising value from the urban mine: recycling critical raw materials

Critical raw materials play a vital role in many products: from batteries to laptops and from MRI scanners to satellites. But for many raw materials, there are major supply risks, for example because they are extracted and processed in specific countries. And some of those countries are increasingly using our dependence on these resources as a means of political pressure.

Europe aims to recycle 25% of critical raw materials by 2030. To address these challenges, the European Commission has drafted the Critical Raw Materials Act. One of its key targets is that Europe should obtain at least 25% of its critical raw materials from recycling by 2030.

Everything about critical raw materials

Discover how TNO is contributing to greater autonomy in critical raw materials. From strategic insights to innovative technologies: read how we are increasing security of supply and making Europe less dependent.

The urban mine

TNO sees recycling as a key pillar of the circular economy. Our research into the Dutch 'urban mine' – the treasure trove of raw materials hidden in our discarded products – shows that there are many opportunities for recovering critical raw materials.

In particular, the recycling of materials such as gallium, lithium, and dysprosium, which are essential for the chip industry, electric vehicles, and wind turbines, could be greatly increased.

TNO focuses on waste streams such as lithium-ion batteries, solar panels, and e-waste. These streams contain many of these critical raw materials and therefore are a potential source for recycling.

The challenges of recycling

While recycling is a crucial strategy to reduce dependence on other countries for these materials, there are still many practical challenges. One of these challenges is the recycling itself. In the Netherlands, recycling of critical materials is still very limited, and many valuable recycling streams disappear abroad, in particular to Asia.

Economic feasibility, stringent environmental requirements, and limited space and electricity connections for recycling plants are major reasons. In addition, the collection of electronic devices is a challenge: in the Netherlands, only 44% of electronic waste was collected in 2020, while the target is 65%.

Furthermore, current policy mainly focuses on the total weight of waste collected, rather than on the presence of critical raw materials. This means that smaller but highly relevant amounts of valuable materials are often lost. For example, only a fraction (0 to 1%) of the permanent magnets present are recovered from large appliances such as washing machines.

Unlock the potential of the urban mine

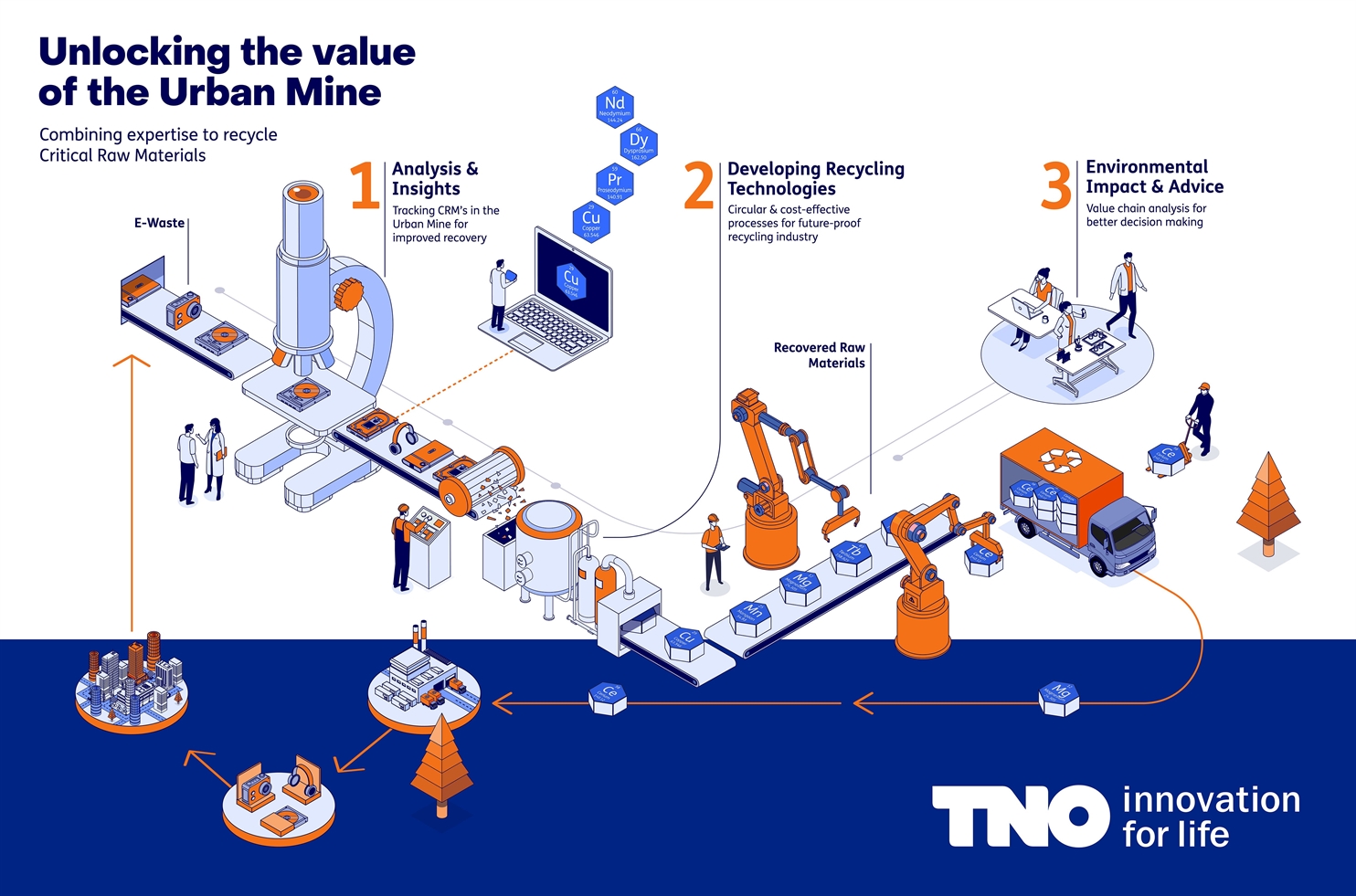

At TNO, we are working towards a future where electronic waste (e-waste) is not lost and instead becomes a source of valuable raw materials. To this end, we are mapping the entire recycling chain, from collection through to the recovery of virgin materials.

We combine technical innovation with understanding of systems and work with partners to develop solutions that are sustainable, circular, and economically viable. This enables us to exploit the value of the urban mine in three ways:

1. Analysis and insights: tracking CRMs in the Urban Mine for improved recycling

TNO is systematically mapping the critical materials that are present in our discarded appliances and how best to recover them. We identify hotspots where the greatest gains can be made and develop strategies to improve collection, sorting, and recycling. By promoting transparency and collaboration between producers, recyclers, and researchers, we will create a more effective recycling system.

2. Developing recycling technologies

We are developing advanced recycling technologies that are not only more sustainable and circular, but also offer higher yields. A recent example is our new technology to recycle batteries from electric vehicles more efficiently. In addition to li-ion batteries, we also apply these technologies to printed circuit boards and solar panels. Our innovations focus on overcoming technological and economic barriers that hinder the recovery of valuable materials.

3. Environmental impact & advice: value chain analysis for better decision-making

By sharing our knowledge of material flows and environmental impacts, we contribute to better decision-making. We analyse the impact of different policy options and help develop regulations that encourage recycling of critical materials. Our knowledge of the entire value chain enables us to make targeted recommendations for a more effective raw materials policy. We also help companies identify and seize opportunities to recover more critical materials.

Discover the opportunities of urban mining

Are you struggling with security of supply, dependency on imports and the lack of insight into secondary raw material flows? TNO offers solutions to use urban mining smartly: from mapping the stock of critical raw materials to developing circular chains and policy. Would you like to know more about our circular solutions for critical raw materials?

Get inspired

Urban mining crucial: more critical and strategic materials from electronics and electrical devices

Prospective Life Cycle Assessments for future-proof product design

Netherlands Materials Observatory (NMO) officially opened

Recovering critical raw materials from LFP Batteries

Circularity of large household appliances in Kenya