3D Nesting: precision quality control and manufacturing efficiency

In general, automating manufacturing leads to more efficiency, lower costs, higher throughput, less waste, higher labour productivity, and predictable lead times. Yet some process steps are a challenge to automate. The challenges are especially significant in the Dutch high-mix, low-volume manufacturing environment, with its small series and requirements for high quality. With their novel 3D Nesting technology, TNO is addressing some of the roadblocks.

‘One of the biggest challenges in (re-)manufacturing is that it is nearly impossible to (re-)manufacture first-time-right. Our patented technology ensures that each component is milled and ground to exact specifications on the first attempt by supporting the operator with some simple tools.’

Creating automated workflows

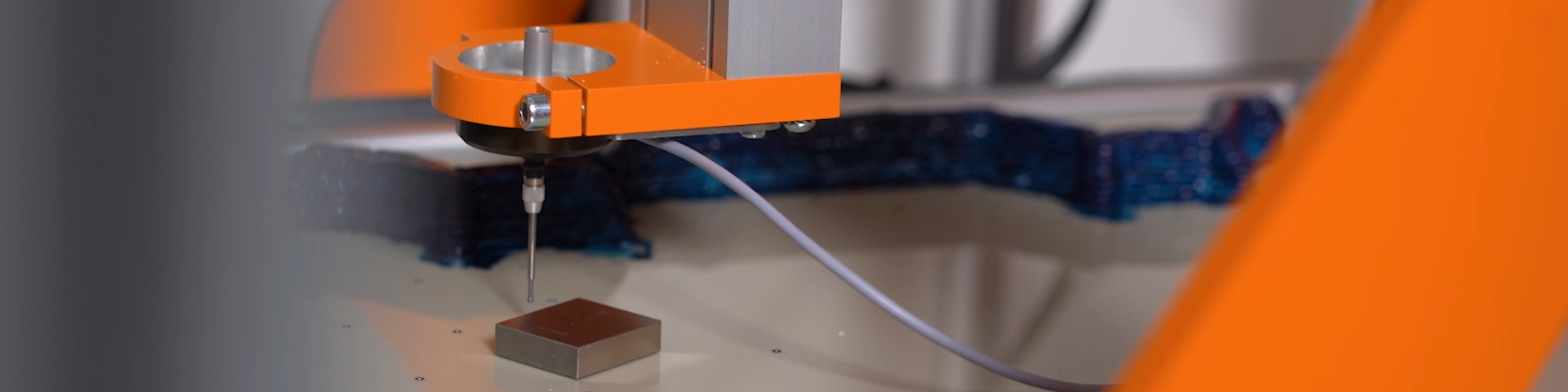

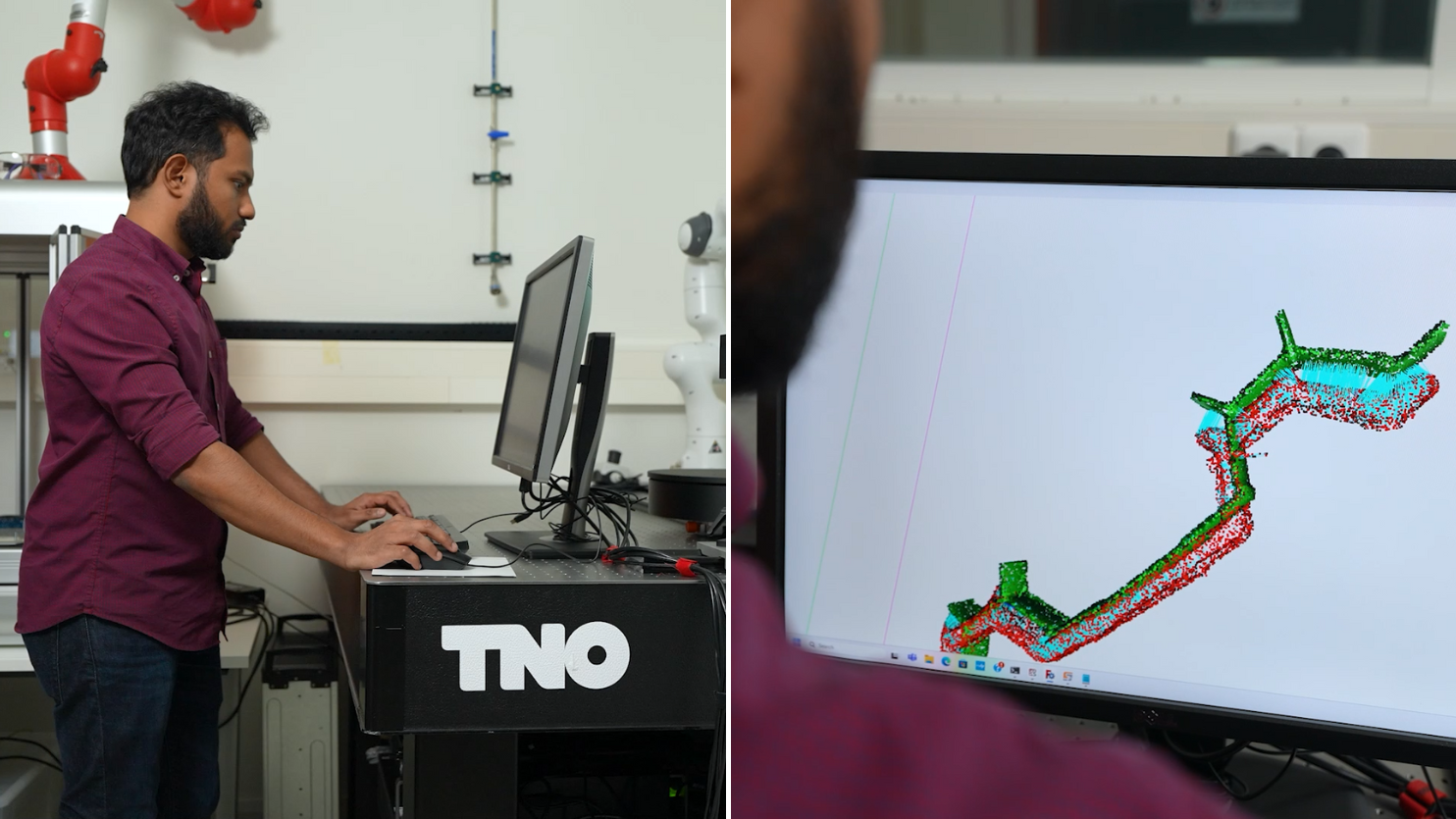

In modern digitized production machining, the work flows from CAD design via CAM to the production machine. Accurate alignment of the various coordinate systems is a tedious task, especially if freeform shapes are involved. TNO has created various methods for Zero-Programming, automated alignment of 3D shapes of CAD, CAM, and 3D camera point clouds. This allows for easy entry into automated manufacturing, even for personnel who have not received extensive training.

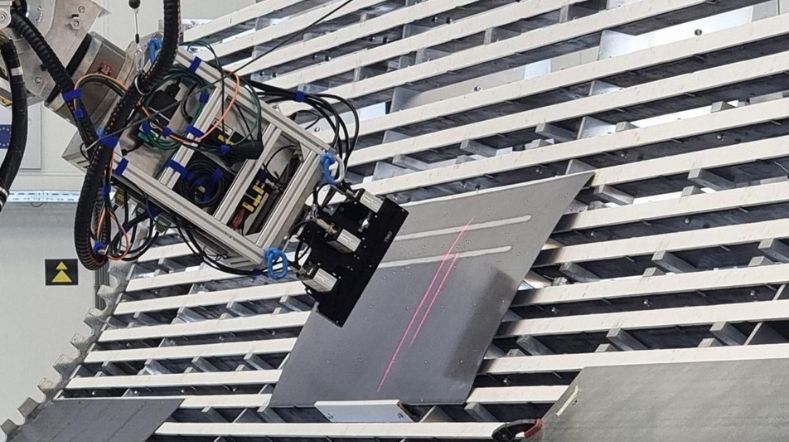

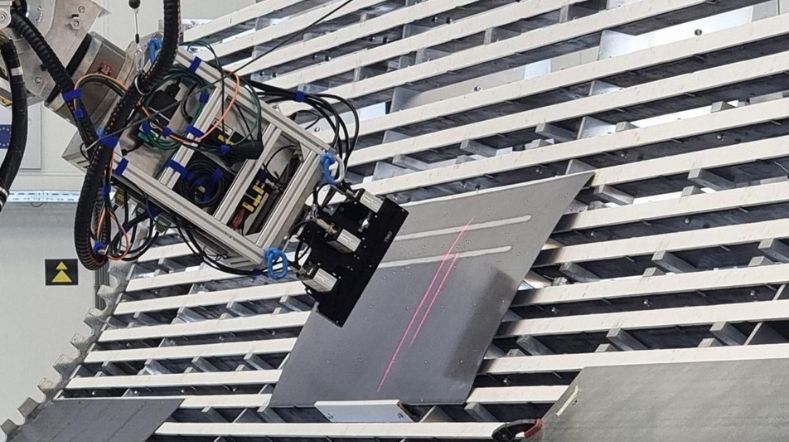

With TNO’s patented 3D Nesting cameras and software, manufacturers can benefit from an automated workflow. Each component – whether produced by Additive Manufacturing or through a CNC milling or casting process – is scanned and aligned with to its CAD or CAM. The components are automatically aligned in the exact pose needed to be accurately (re)worked. Excess material is removed or added to fill in gaps, in a single iteration. This saves a significant amount of time and ensures higher quality than manual (re)working processes. Early users of 3D Nesting technology report reductions in processing time ranging from 10% to 30%.

Accurate edge sealing and beyond

The very same technology has also proven to be effective for other applications, such as edge sealing. As each unique component is produced, assembled, and trimmed, the unique and varied edges of the components must be accurately sealed. With 3D Nesting cameras, software, and automated programming of 3D complex shapes, a wide variety of parts can be autonomously sealed with precision. The system processes component parameters on the fly and simplifies implementation on the shop floor.

By automating the edge sealing process, manufacturers can eliminate the need for human intervention, accelerate production, reduce resin usage, better utilise human labour, and ensure consistent quality according to precise specifications. This leads to less reworking and predictable lead times.

The very same technology can also be used to repair components that have worn down from use, and must be repaired with replacement material. With the CAD model as a guide, new material is placed with precision in the places where it is needed, eliminating waste, saving energy and materials, and reducing the need for reworking. Other quality control points in the manufacturing process can also benefit from the technology, including support for operator instructions.

TNO also sees the possibility to utilise 3D Nesting to calculate the time, costs, and processes needed to produce new components from 3D CAD files and simulate manufacturing to ensure feasibility. Since the calibration and reworking machines operate using Machine Learning and other technologies, the system even has the potential to systematically improve the speed and accuracy of alignment, or even automatically correct the errors and excesses that happen repeatedly, resulting in a more efficient process overall.

‘Our patented and fully automated system effectively identifies only the precise reworking, edge sealing, or re-manufacturing that needs to be done, and then performs it autonomously, with extreme accuracy, in real time for each component.’

Enable automated workflows today

Bringing this remarkable technology to industry partners is just a few steps away. TNO is working with integrators, milling machine providers, and other partners to optimise the technology and adjust it for specific applications. Eventually, TNO aims to work with integrators to develop an off-the-shelf product for any manufacturing system.

3D Nesting technology can be added to any standard manufacturing system with plug-and-play ease, and optimise a variety of steps of the manufacturing process. Interested in licensing the technology, or uncovering how it can be applied to any stage of your manufacturing process that requires reworking, quality control, or precision correction? Get in touch today to find out more.

How does it work?

This short video explains TNO’s 3D Nesting technology as it is applied to the reworking process in Additive Manufacturing. With minimal human intervention and maximum efficiency, 3D Nesting is improving production, one component at a time.

Optimised edge sealing

Composite manufacturer Airborne sought a precision solution for edge sealing of the approximately 600 unique components they produce. In partnership with Airborne, TNO fully automated the edge sealing process to increase Airborne's throughput, efficiency, and speed. Watch the video here.

Get inspired

SEAMIIC: Autonomous parts handling and quality control

Partnering for mutual progress

TNO spin-off Scenexus secures 1.6 million euro investment

Scale up: manufacturing throughput and quality

Non-destructive inspection