TNO achieves breakthrough in silicon solar cell metallisation technology: fully copper-metallised silicon heterojunction solar cell

TNO has succeeded in applying copper electrodes to silicon heterojunction solar cells using a new screen-printing process. With this innovation, almost the same amount of electricity can be generated as with the traditionally used silver. The use of copper makes solar cell production both cheaper and more sustainable, while also providing resilience against future silver scarcity and price increases. The results will be presented at the European Photovoltaic Solar Energy Conference (EUPVSEC) in Bilbao this week.

Performance of solar cells with copper-metallisation comparable to those with silver-metallisation

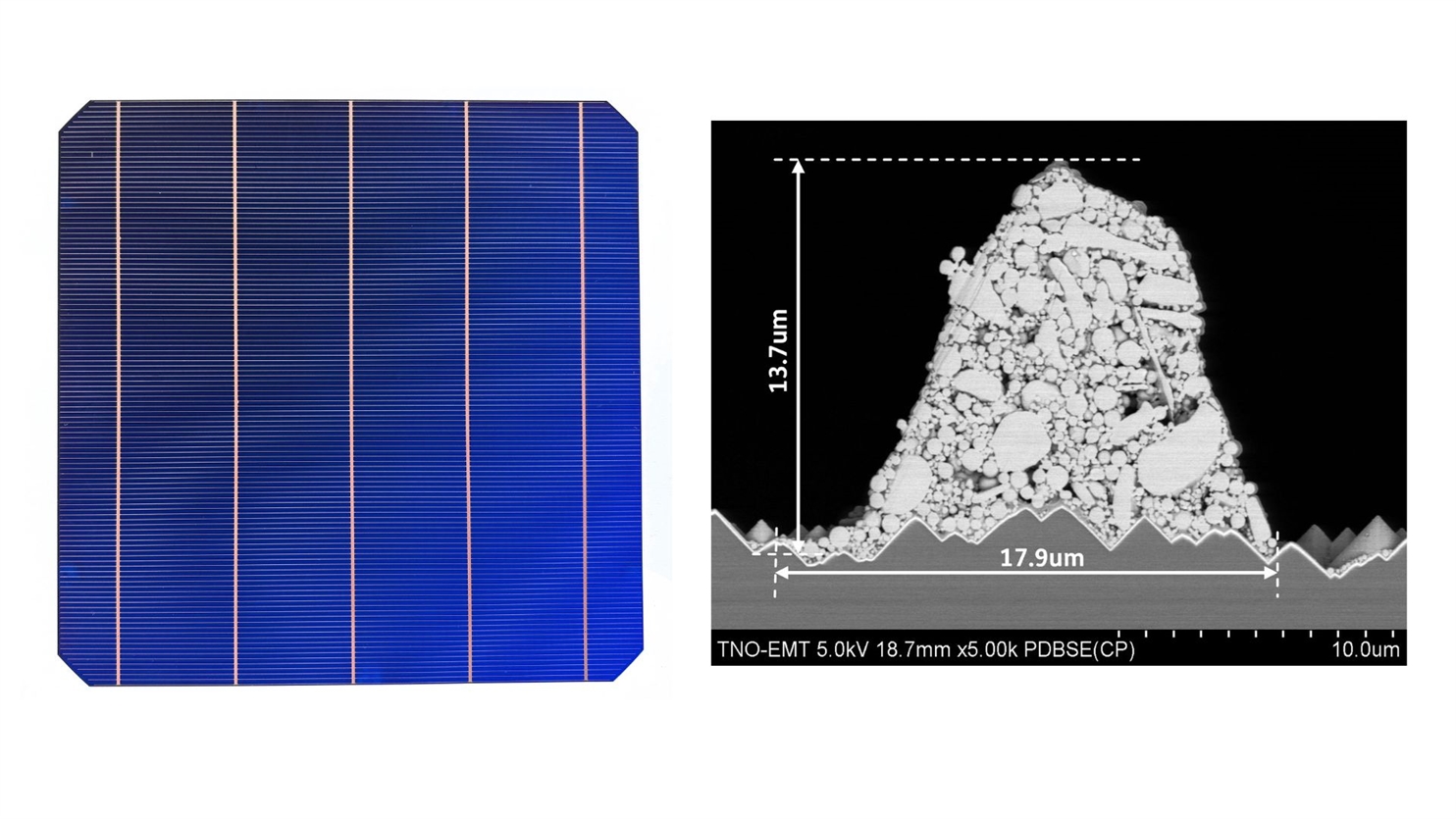

The new process, using the existing screen print production technology, enables the application of very narrow copper lines on both the front and back sides of the solar cells. The performance of these copper-metallised cells is within 1% of traditional silver-metallized cells.

Copper is currently 100 times cheaper and 1,000 times more abundant on the market than silver, enabling solar production to scale up sustainably without reliance on that scarce resource.

Global demand for solar energy is growing rapidly. By 2035, annual addition of PV systems could reach nearly 1 terawatt. At such a scale, up to 50% of annual global silver production would be needed for solar cells alone.

This research was carried out in close collaboration with Dutch PV start-up MCPV B.V. and a company specialising in metallisation pastes.

'This result opens an important opportunity, in parallel to Cu electroplating technology, for silver-free metallisation in the HJT solar cell manufacturing without extra investments in equipment or added process complexity. It also shows strong potential for future high-efficiency perovskite/silicon tandem solar cells.'

Next steps

TNO is continuing work on improving the copper metallisation process, developing advanced solar module technology compatible with this method, and testing the long-term reliability of the resulting modules. Because the method uses screen-printing technology, industrial implementation is expected to be relatively straightforward. Together with partners such as MCPV B.V. work is underway to ensure rapid and sustainable industrial application.

'This result is indeed very important for sustainable heterojunction scale-up. Reducing the silver cost and availability burdens at little efficiency penalty, while using standard manufacturing technologies is offering a fast-track introduction into production.'

Support and Collaboration

These results were achieved with support from the SusCon project, partly funded by TKI Urban Energy, part of the Top Consortia for Knowledge and Innovation (TKIs) of the Ministry of Economic Affairs and Climate Policy, and SolarNL, funded by the National Growth Fund.

Get inspired

New production concept enables large-scale custom application of solar film

Shade screens with rollable solar foil combines energy generation with climate control in greenhouses

Dutch consortium develops manufacturing technology for perovskite solar cells

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

The next generation of solar technologies