A View of the Universe: TNO Contributes to TMT Success

TNO is making a powerful contribution to the Thirty Meter Telescope (TMT). Scientists strive to explore deeper regions of space with more clarity than ever. Astronomers work to uncover the origins of stars. Experts search for life on other planets. Through it all, one thing is clear: the key to deeper understanding of the universe is cooperation and innovation.

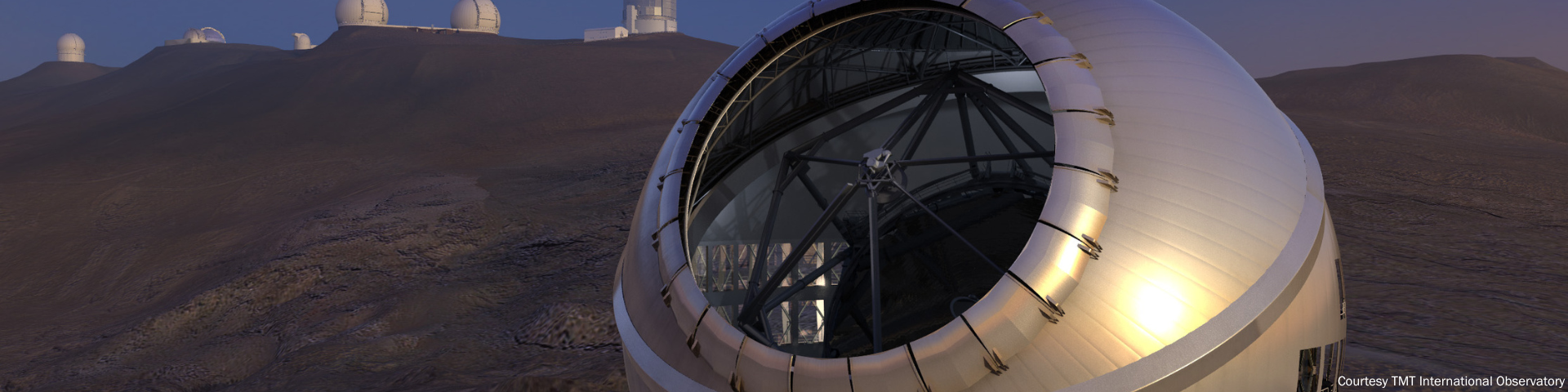

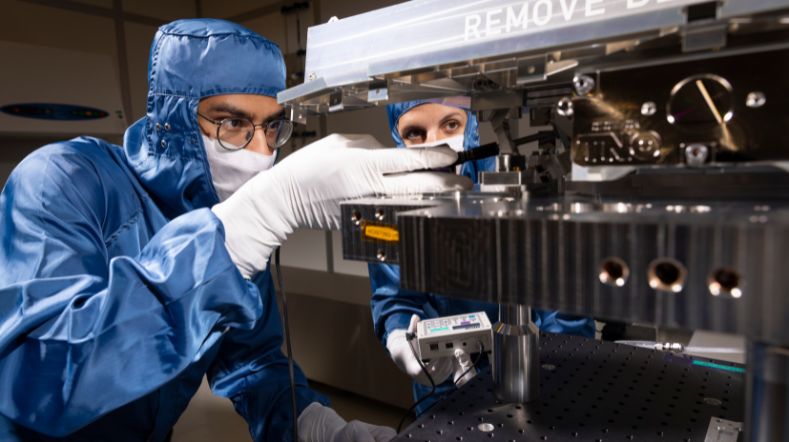

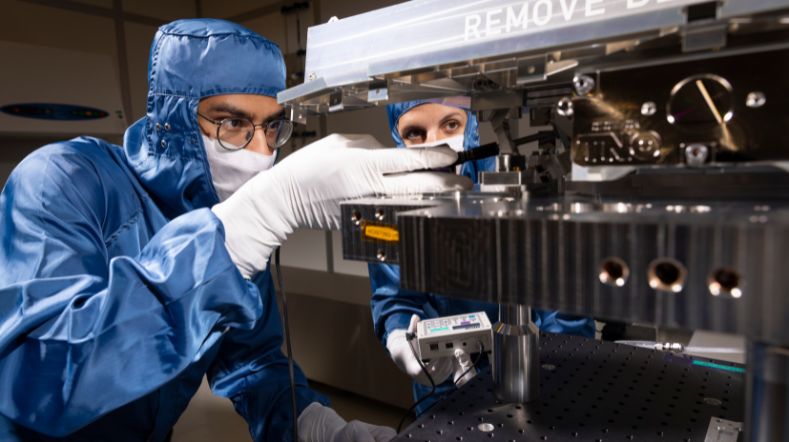

Once again, TNO and our partners have been called upon to contribute to one of the Extremely Large Telescopes (ELTs) that will provide the answers to questions people have been asking since the beginning of time. The team responsible for building the Thirty Meter Telescope (TMT) – which will be one of the largest telescopes ever built – contacted TNO with a specific request. Aware of our work on the European ELT, and our previous support in improving the design of TMT Segment Support Assembly (SSA), TMT asked TNO to design an SSA Module Acceptance Test Tool (SMATT). As always, TNO was eager to take part in the ground-breaking project.

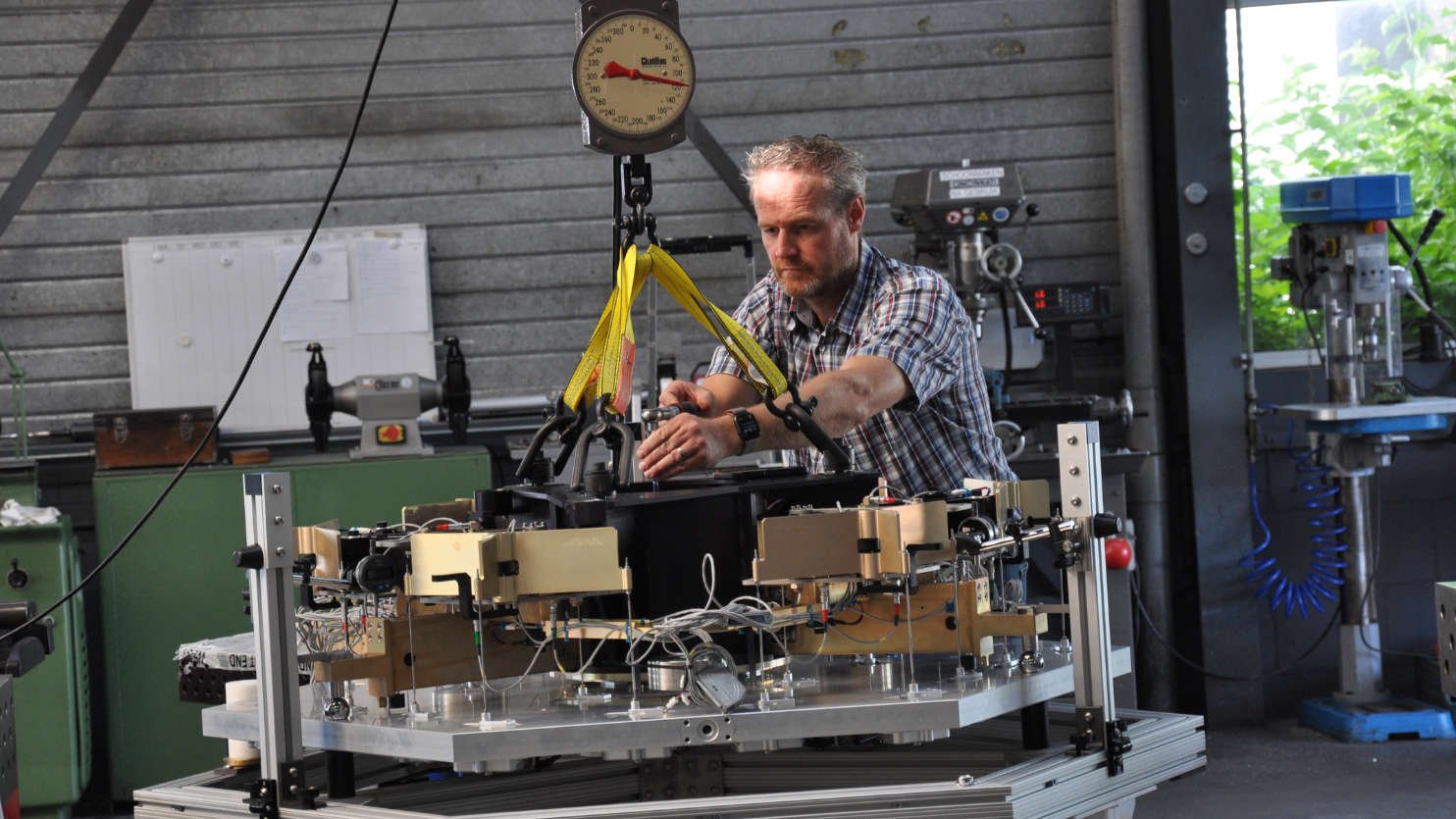

The TMT team visited the Netherlands earlier this year to check on the progress of the project and conduct the first testing of the SMATT. Final testing will take place in the Q1 2024, and the TNO will deliver the final SMATT in Q2 2024.

’No single organisation can accomplish as much as a group of cooperating partners can.’

Exploration through collaboration

‘When it comes to opto-mechatronic equipment for space and scientific instrumentation, no single organisation can accomplish as much as a group of cooperating partners can,’ explains Nico van der Heiden, Project Manager of the TMT SMATT development. ‘To ensure successful completion of the TMT assignment, we worked with several local partners like S&T and Technolution, amongst others. Collaborations like these are essential to our collective success.’

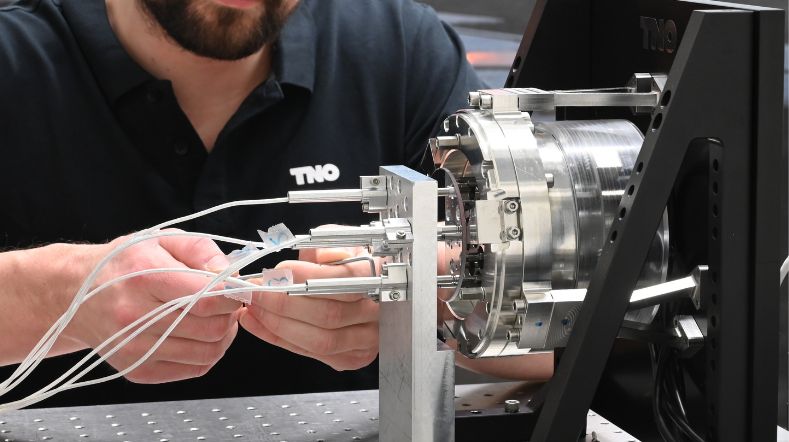

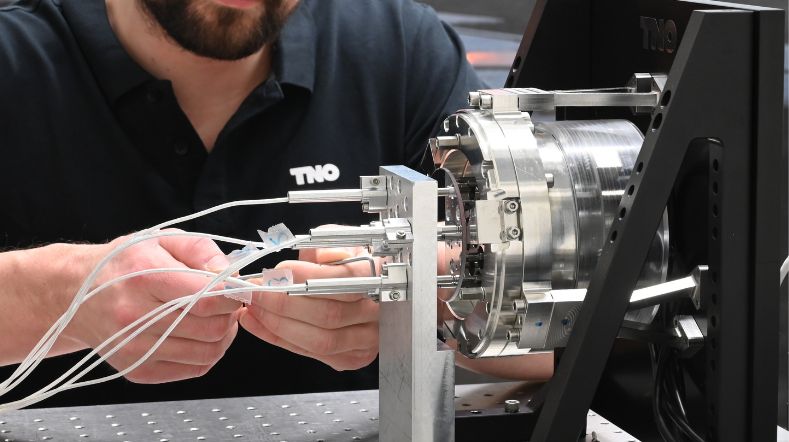

That success is coming into clear focus. TMT’s M1 system – or primary mirror – will be made up of 492 individual, 1.4-meter segments, all maintaining near-perfect shape and alignment to work together as a single, 30-meter-diameter mirror. A highly complex set of whiffletree support systems, called SSAs, sit beneath each hexagonal mirror segment. The SSA controls the mirror’s surface to prevent bending and warping at nanometer accuracy. A large mirror like this one, that can maintain near-perfect shape, will allow astronomers to look deeper into space with more clarity and precision than ever before possible with a ground-based telescope.

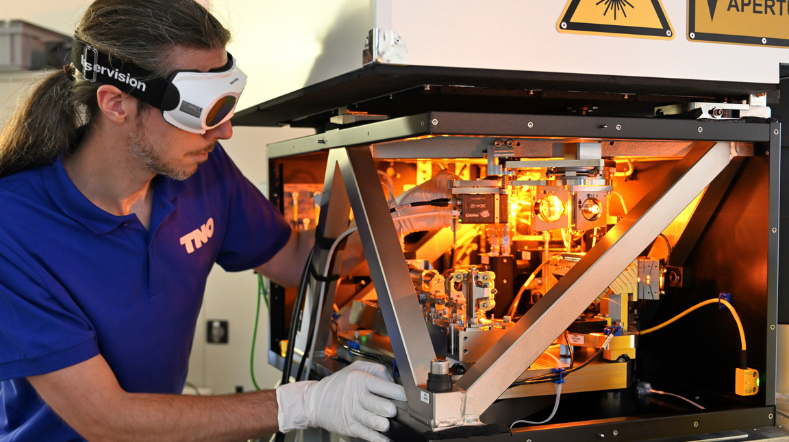

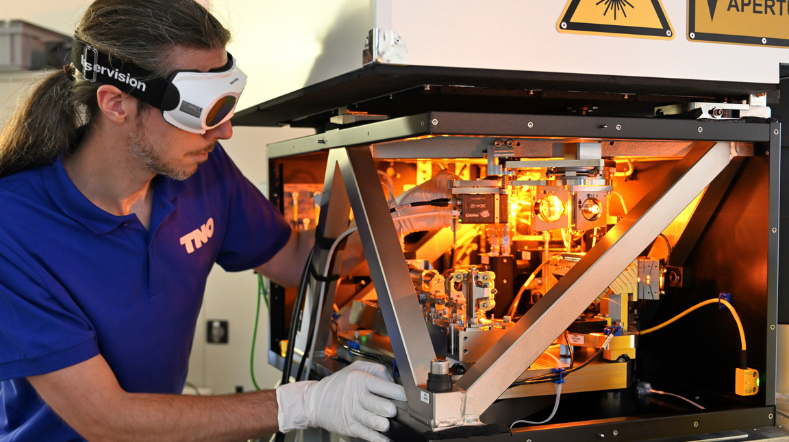

‘The SMATT we developed is an automated way to test each SSA and mirror segment to ensure it meets exacting requirements to nanometer precision.’

Testing for confidence

As the components for TMT are being built, a system was required to test the SSAs in an efficient and effective way. ‘The shape of each mirror segment has to be controlled in an infinite number of pointing directions and at utmost precision to make the telescope effective,’ says Matthew Maniscalco, Senior Business Developer in TNO Space Scientific Instrumentation.

‘It’s optimal to test each of the more than 500 structures of the system (counting spares) as they’re being made,’ Matthew continues. ‘With the right test equipment, we can create the exact gravitational forces, and precisely measure the corresponding forces the SSAs will impart to their mirrors. This will ensure precise mirror shape is maintained. Now, as each SSA is manufactured – whether in India or in California – manufacturers will use the SMATT to ensure that each SSA can withstand the conditions.’

To develop the SMATT, TNO was able to modify the design of the Force Field Test (FFT) tool developed for testing the ELT segment supports. Modifications were made according to the exact specifications for the TMT segment supports. The SMATT is also fully automated. ‘The SMATT will measure the loads between the mirror and the SSA at every relevant gravity gradient,’ Nico says. ‘This ensures the most thorough and effective testing possible.’ Automated testing is important for timely and accurate results when testing hundreds of systems. In its press release about the successful cooperation with TNO, TMT calls the SMATT ‘critical’.

Preparing for more

Successful completion of the TMT project will be a great accomplishment, but Matthew, Nico and the world-class teams of engineers and scientists at TNO are eager to create new partnerships and continue advancing the precision of optical instrumentation that will answer the big questions of the universe. ‘We’re proud to be part of such a significant project like the TMT. We encourage other organisations struggling with challenges related to nanometer-precision space and scientific instrumentation to get in touch. It’s TNO’s mission to help,’ Matthew says.

If you want to know more about these projects, please visit the officials websites of ELT or TMT.

‘The SMATT unit is critical because it will be used to verify all TMT’s segment support structures.’

Looking beyond

TMT is one of many space and scientific instrumentation projects to which TNO has made significant contributions. Find out more about our Ground-Based Astronomy work.

Get inspired

Optics

Space systems engineering

Laser projection systems

Optomechatronics

Quantum technology