Battery technology: 4 developments according to the Battery Lab

The development of battery technology is advancing at lightning speed. Five years ago, battery-electric lorries were almost unimaginable. Today, they are widely in use, and we are even seeing applications that are far more demanding, such as electric aircraft. Experts Erik Hoedemaekers and Jan-Willem Sangers have identified four key trends in the battery industry.

What are the four key developments in battery technology?

1. Growing number of battery applications calls for rapid validation and testing

'As batteries have become increasingly better and more affordable over the years, we are seeing entirely new areas of application emerge,' says Jan-Willem. This is evident, for example, in drones. 'In the past, a drone was a children’s toy that could barely fly for more than five minutes,' Jan-Willem explains. 'Nowadays, a drone is a serious agricultural or film-making tool capable of carrying heavy loads and achieving long flight times.'

These new areas of application bring their own challenges. For instance, drones have different safety requirements compared to batteries for electric transport or maritime uses. 'We are moving towards other mobility applications for batteries, which means an ever-growing diversity of products with unique characteristics and requirements must be tested,' Jan-Willem adds.

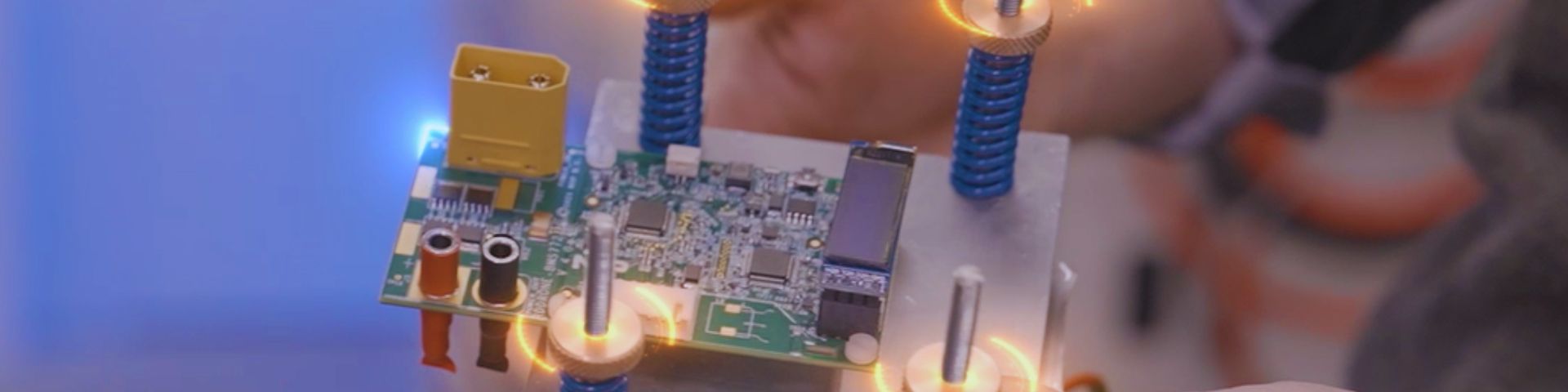

This growing diversity demands flexibility in the battery lab: new components, battery modules or packs must be tested quickly. That is why TNO is working on prototyping facilities to validate new concepts rapidly. 'This enables us to quickly turn innovations into prototypes and demonstrate whether the desired results are achieved,' Erik explains.

Want to know more?

Discover how Battery Lab drives progress in battery technology and supports partners in accelerating electrification.

2. Stricter safety requirements and more realistic gas analysis

In addition to a greater diversity of applications, TNO experts are seeing a shift in the type of testing requests coming in. Erik explains: 'We are receiving more and more questions about safety testing, particularly from the aviation sector. Think of manufacturers of drones and small aircraft. In that sector, safety requirements are typically even stricter than, for example, in the automotive industry.'

This shift has a clear cause: new EU regulations require the industry to test in a different way. For certain applications, battery manufacturers must be able to demonstrate which specific gases are released and in what quantities during a thermal runaway – an uncontrollable chain reaction in which an overheated battery becomes progressively hotter and can eventually rupture or catch fire.

At the Battery Lab, TNO addresses this specific need. 'In our lab, we can safely induce thermal runaway in batteries and perform gas analyses during the process, even for larger systems,' Erik explains. The value lies in the combination: being able to safely test thermal runaway (and its propagation) and immediately carry out a detailed analysis of which gases are released. 'That combination is commercially hardly available,' Erik adds.

'The voltages at which systems operate – especially in vehicles, but also in stationary systems – are getting higher and higher.'

3. More powerful battery systems with higher voltages

'The voltages at which systems operate – especially in vehicles, but also in stationary systems – are getting higher and higher,' observes Jan-Willem from the testing requests coming in. Batteries with higher voltages are more efficient; they require lower currents for the same power output.

Many car manufacturers, for example, are making the transition from 400 volts to 800 volts and already offer electric vehicles (EVs) with 800-volt battery systems. For heavy-duty vehicles, batteries can even exceed 800 volts. This development imposes new demands on testing facilities; test equipment must be capable of handling higher voltages.

TNO is anticipating this by expanding the Battery Lab’s testing capacity to 'significantly above 1,000 volts,' as the expectation is that batteries will only become more powerful. 'We need to try to stay ahead of the market so that we can continue testing the available systems,' Jan-Willem emphasises.

'The industry no longer wants to simply look at how a battery behaves, but also understand why it behaves that way.'

4. Shift towards a deeper understanding of chemical processes

Finally, the experts at TNO’s Battery Lab are seeing a fundamental shift in how batteries are tested. 'The industry no longer wants to simply look at how a battery behaves, but also understand why it behaves that way, what is happening chemically inside the battery,' says Erik.

'The problem with traditional testing is that you have to test every new battery from scratch. That takes a lot of time,' Erik explains. 'If you understand what happens at component level, you can make predictions much faster.' This can be done using physical models that describe the electrochemical process. Instead of merely observing from the outside, the focus is on what is really happening to the electrodes and other components inside the battery.

TNO is therefore investing in equipment to dismantle batteries and analyse the individual parts. Erik: 'By understanding how electrodes and other components react, we can create models that deliver reliable lifetime predictions much more quickly.'

Responding to market needs

Gas analysis, higher voltages, prototyping, component analysis – four different developments with one thing in common: they show how important it is to keep pace with a rapidly changing industry. From new safety requirements to unexpected areas of application.

'We try to stay as close as possible to the research questions that arise,' says Jan-Willem. But what those questions will be tomorrow is not always predictable in such a fast-moving industry. That is why TNO also looks to the market itself for direction. 'Input on market needs is very welcome,' Erik emphasises. TNO’s Battery Lab is keen to work with (new) partners to explore what is possible and ensure future investments align as closely as possible with market demands.

Get inspired

How far can you travel in an electric car?

National Growth Fund invests in Dutch battery consortium for heavy duty transport

TNO opens test cell for sustainable marine engines

Fuel cells crucial for decarbonising heavy-duty transport and non-road machinery

Health of electric bus batteries now measurable on-site via charger