MOF4Biogas: shaping the future of CO₂ capture from biogas

Status project

present - December 2026

In cooperation with

CatOlyst BV, Colsen BV and Procat Tech LLP

Many small-scale CO₂ emitters — such as decentralized biogas plants — face a critical challenge: a lack of affordable and efficient carbon capture solutions. Traditional technologies are often too large, too energy-intensive, or too costly to apply at small scale. As a result, valuable CO₂ streams remain uncaptured, and the potential of biogas as a fully climate-neutral energy source remains underutilized.

In the MOF4Biogas project partners CatOlyst BV, Colsen BV, Procat Tech LLP and TNO are addressing this gap by combining cutting-edge material innovation with smart process design. By shaping advanced Metal-Organic Framework (MOF) adsorbents into industrially usable forms, and integrating them into a scalable CO₂ capture system, we aim to unlock a compact, cost-effective solution for upgrading biogas to biomethane (groen gas).

This supports the climate goals to increase green gas supply — and contributes to broader international efforts to decarbonize small-scale energy production through the application of BECCS (bioenergy with carbon capture and storage).

Turning advanced materials into real-world solutions

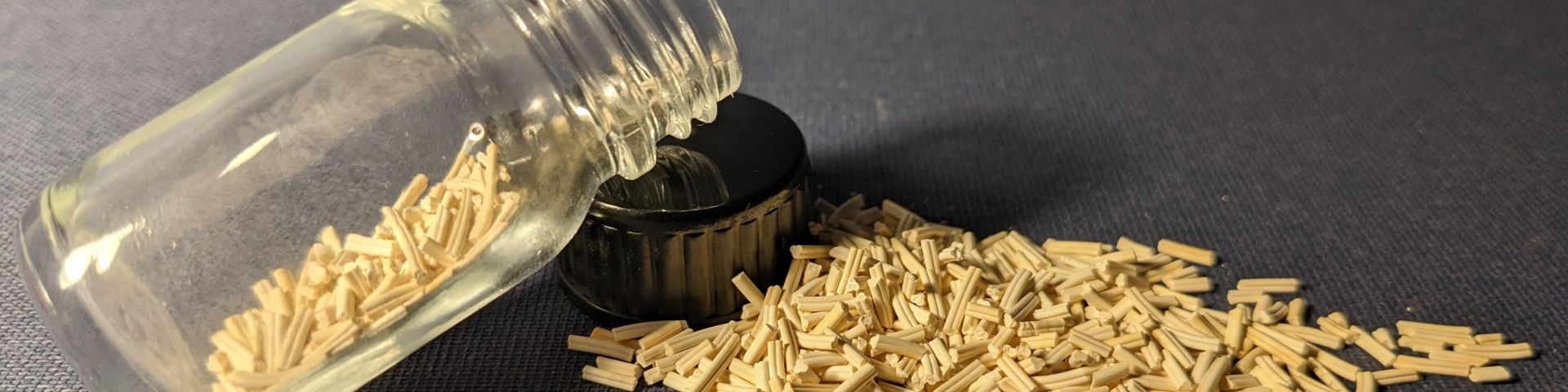

TNO and partners are developing a novel, energy- and cost-efficient CO₂ capture process based on shaped MOF adsorbents. These advanced porous materials have shown great promise in CO₂ capture, but until now, their industrial use has been limited by their fragile powder form.

For the first time, this project explores various shaped forms of MOF adsorbents—such as extrudates, trilobes and monoliths—under real process conditions. This enables the development of a robust and scalable solution that meets industrial requirements for performance, durability, and pressure drop.

Bridging materials and systems

As lead research and innovation partner, TNO plays a central role in turning materials research into integrated, scalable technology. TNO is:

- Evaluating the performance of shaped MOF adsorbents in lab and pilot settings;

- Designing and modelling the full CO₂ capture process using advanced simulation tools;

- Assessing the technical and economic feasibility of industrial implementation;

- Connecting scientific innovation to system-level application.

This integrated approach ensures that the MOF4Biogas solution is both technically sound and practically viable — ready to support the energy transition at small scale.

From powder to performance

MOFs are part of the microporous materials family, like zeolites and alumina, but unlike these, they have not yet been widely applied at scale due to their powdery, fragile structure. This changes with MOF4Biogas.

CatOlyst BV has developed a novel shaping technology that transforms MOF powder into mechanically stable forms without compromising its adsorption properties. These shaped adsorbents can now be used in real industrial systems.

Procat Tech LLP, a catalyst manufacturer, is scaling up production to ensure industrial readiness, while TNO and Colsen are analyzing the performance of these forms to guide process design.

Industrial process design meets real-world needs

With the material bottleneck resolved, the focus shifts to integrating these shaped MOFs into a compact and efficient carbon capture process. TNO’s in-house modelling tools are being used to simulate and optimize system performance under a range of conditions.

By testing multiple MOF shapes, the team can identify the best match between material structure and process design—ensuring an optimal balance between energy use, pressure drop, and CO₂ removal efficiency. Based on these results Colsen BV will provide the techno economic evaluation for optimal process performance.

The result: a modular, cost-effective CCS system suitable for small-scale, decentralized applications.

Partners in innovation

The MOF4Biogas consortium brings together expertise across the value chain:

- CatOlyst BV – Developer of the MOF shaping process and key material innovation partner;

- Colsen BV – Expert in biogas and environmental technologies, supporting process development and application;

- Procat Tech LLP – Indian-based manufacturer scaling up the shaped MOFs for industrial deployment;

- TNO – Leading the process design, performance evaluation and system integration;

- Advisory board – InnovationQuarter and OCAP CO₂ BV contribute strategic insights and market alignment.

Impact

MOF4Biogas demonstrates how collaboration between research, industry and technology developers can unlock advanced materials for real-world climate solutions.

By developing a technically robust and economically viable CO₂ capture process tailored to small-scale emitters, the project contributes directly to the Dutch and European energy transition—and offers a replicable model for clean energy systems worldwide.

Get inspired

TAKE-OFF project: From CO2 and hydrogen to sustainable aviation fuels

Netherlands–India: Collaboration for green hydrogen

Temporary Special Economic Zone around Rotterdam can prevent climate delays and GDP losses

Sunlight-driven technology for sustainable chemistry and solar fuels

The energy system of the future