Pioneering towards a robust supply chain of Critical Raw Materials

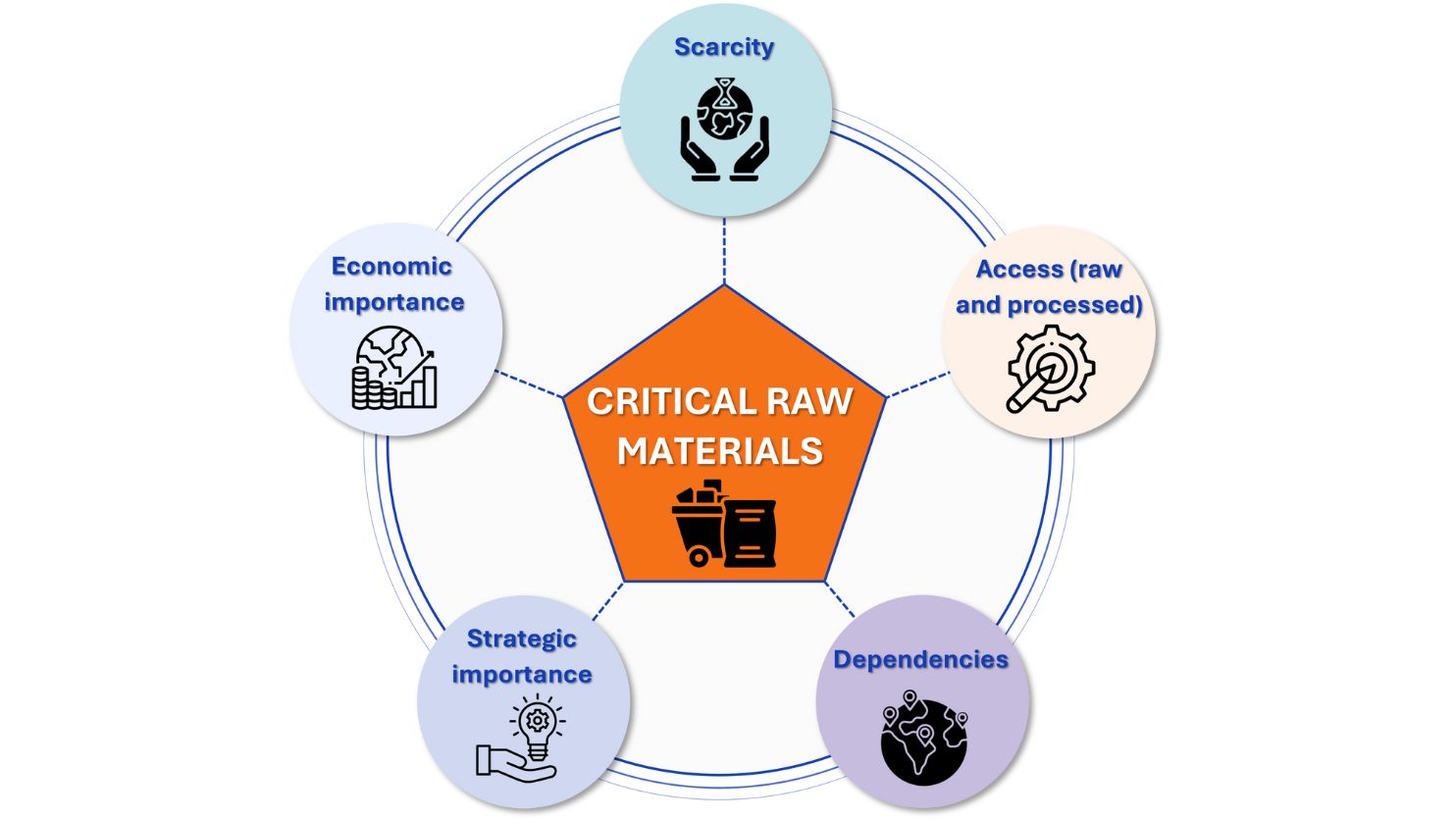

Our industry relies heavily on a secure supply of Critical Raw Materials (CRM). Particularly as we accelerate the energy and materials transition. For instance, we need rare earth metals from China to make permanent magnets for wind turbines. To prevent supply risks and reduce costs, TNO develops innovative materials. This includes safe, sustainable and economically viable alternatives to CRMs, ensuring a robust CRM supply chain.

Material developments to replace or reduce CRMs

In line with the Critical Raw Materials Act, we are developing alternatives to critical raw materials. To increase supply chain robustness, facilitate the energy transition, and guarantee the competitiveness of Dutch and European industry. Our key areas of development include:

1. Alternative Sourcing

We map out where CRMs are currently used in Dutch and European industry and what waste streams are produced in the process. Then we look into developing processes to extract these critical materials from the waste stream and use them in the production of new high value materials or products. See our spotlight innovation, using vanadium waste streams for smart windows.

2. Material Replacement

We identify products that use critical materials. We then search for, or develop, replacement materials that are less critical and often cheaper. In doing so, we maintain or even improve functionality and performance. See our spotlight innovation, making green hydrogen production less dependent on CRMs.

3. Design for Circularity

TNO develops new materials and processes to facilitate recycling and reuse of CRMs at a product's end-of-life. This approach is aiming to make products more recyclable from the start. For instance, the rare earth metals in permanent magnets for wind turbine generators are difficult to extract and to recycle when integrated into large components. To facilitate disassembly of components at their end of life, TNO is developing modular strategies like reversible adhesives for various applications.

Spotlight innovations

TNO is working on various innovations in the field of critical materials. Here you find an overview.

Vanadium is a critical raw material used in batteries, steel and titanium alloys, and as catalyst in e.g. rubber production. More than 95% of global mining and 80% of EU sourcing of vanadium comes from just four countries: Russia, China, Brazil, and South Africa. At the same time, European industry produces thousands of tons of vanadium-containing waste annually, which is disposed of at high costs.

TNO's solution

We've created a new process to extract highly pure vanadium pentoxide directly from spent industrial catalysts. We use the extracted vanadium as feedstock for another innovation developed by TNO: a smart window coating that uses vanadium oxide to provide self-adaptive solar heat regulation in buildings.

Impact

- Waste streams become a valuable resource of critical materials

- Business case for companies who dispose of waste containing high value materials

- Reduce dependency on foreign suppliers

- Even more impact when transferred to other and more critical materials like platinum, iridium, and lithium

Green hydrogen is essential for the energy transition. Proton Exchange Membrane Water Electrolysis (PEMWE) is one of the most promising technologies for producing green hydrogen efficiently. However, current systems rely heavily on critical materials such as iridium, platinum and titanium. More than 50% of a PEMWE system's cost comes from titanium alone.

TNO's solution

Building on our expertise in PEMWE technology, we're developing innovations on different levels. The first level is radical reduction. We’ve developed a new catalyst that uses 200 times less iridium than conventional systems. The second level is material replacement, such as developing platinum-free anti-corrosion coatings and reducing costs through replacing titanium with stainless steel. The third level is design for recycling: re-engineering PEMWE systems for easier disassembly and material recovery at end-of-life.

Impact

- 200x reduction in iridium use

- Potential significant cost reduction through titanium replacement

- Reduced supply risk for green hydrogen production

- Accelerate the energy transition while strengthening Europe's technological autonomy

Everything about critical raw materials

Discover how TNO is contributing to greater autonomy in critical raw materials. From strategic insights to innovative technologies: read how we are increasing security of supply and making Europe less dependent.

Making water electrolysis cleaner and safer

When developing circular replacements for CRMs, we’re not only working on reducing dependence on scarce resources. We are also focusing on new materials development for the replacement of toxic materials, with the goal of making water electrolysis cleaner and safer. As an example, we’re developing PFAS-free membranes to replace the current NafionTM membrane used in these systems.

Partner with TNO for CRM solutions

Whether you're facing supply risks with critical materials, or generating waste streams containing valuable resources: TNO can help you design new processes, develop alternatives and make valuable use of waste. Contact us for more information and co-development.

Get inspired

New routes for sorting and composite separation

Progress in circular packaging for soups and sauces

Biobased plasticisers: from compliance to competitive edge

Microplastics in clothing

Early results show the potential of circular healthcare plastics