CRM Lion: locally recovering critical materials from lithium-ion batteries

Status project

April 2025 - November 2029

In cooperation with

Back-to-Battery, Eurofins, Nth Cycle, TU Delft and WMC

What happens to used batteries, such as those from laptops or electric cars? After collection, these are mainly shredded and exported to other countries for further processing. At the same time, we are dependent on foreign sources for the critical raw materials used in batteries. This needs to change if we want to increase our sustainability and autonomous position. That is why, on December 1st 2025, the four-year NGF project CRM Lion started, with TNO participating. The aim is to locally recover raw materials from old lithium-ion batteries for reuse by Dutch and European industry.

A local circular chain: why is it important?

Lithium-ion batteries contain a significant amount of critical materials, such as lithium, cobalt, manganese, and nickel. These raw materials largely originate from Asia.

After these batteries are used, the raw materials can be recovered. However, instead, old batteries are exported back to Asia in the form of shredded, powdery material (black mass). This black mass is then processed back into raw materials in Asia.

To gain more autonomy in the field of batteries, the four-year CRM Lion project will start on 1 December, with an investment of 23 million euros, of which 13 million euros is financed by the National Growth Fund.

The goal is to establish our own circular chain to process batteries locally into new raw materials, so that we can produce new batteries ourselves. That is what TNO is working on, together with Back-to-Battery, Eurofins, Nth Cycle, TU Delft, and WMC in the CRM Lion project (Recovery of Critical Raw Materials from Li-ion Batteries through improved Recycling Processes).

How will we recycle batteries?

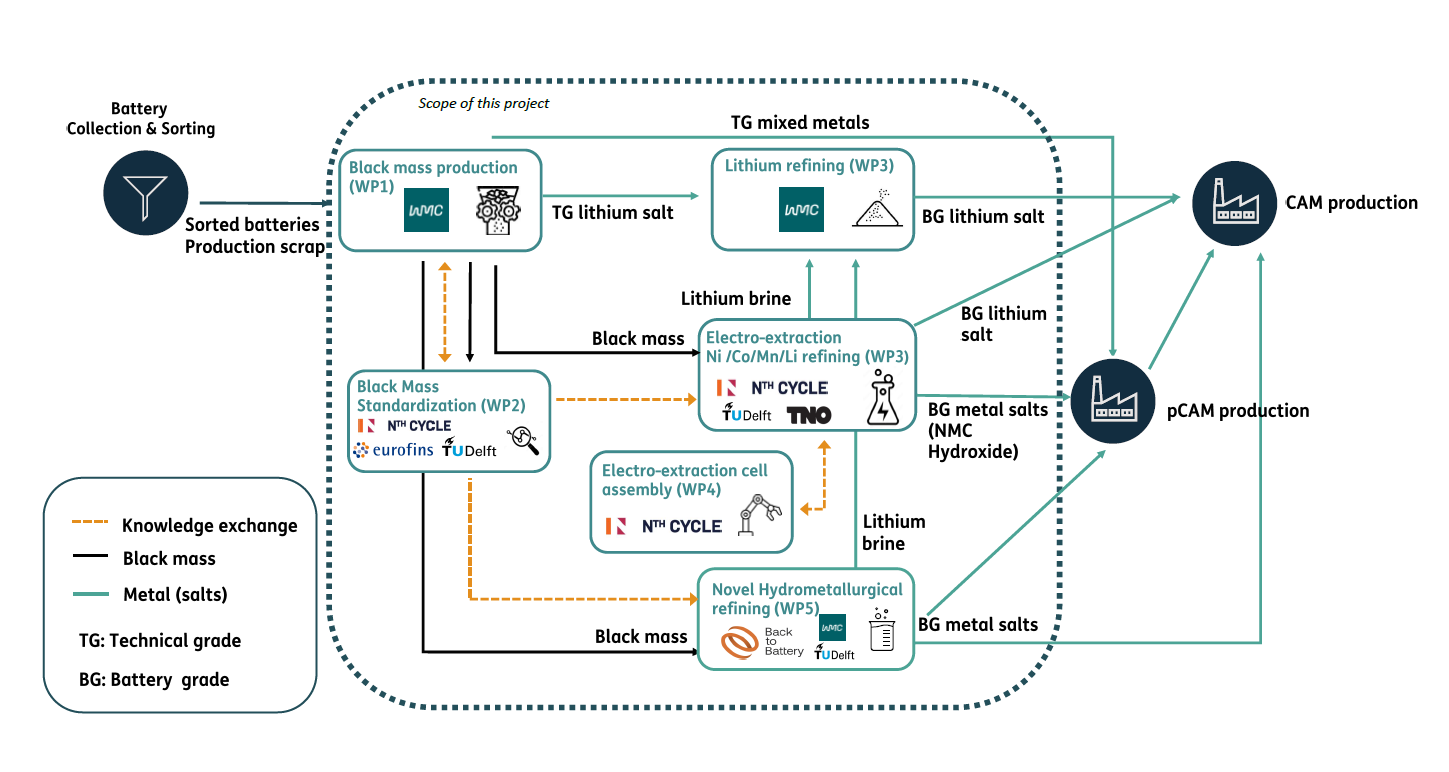

CRM Lion consists of five work packages, focusing on the following three topics, which are also shown in the figure below:

Instead of exporting black mass to Asia, we are investigating how to optimise the production of black mass and recover the critical raw materials as effectively as possible in the Netherlands.

Batteries, and therefore also the black mass produced from these batteries, vary greatly in composition and quality. We are establishing standardised methods to measure the quality of black mass quickly and reliably. This will give us better insight into the quality of black mass, which also makes the further refining of critical materials more efficient.

We are working on new, more sustainable ways to recover materials from batteries: using hydrometallurgical and electrochemical techniques, we extract materials from both sorted and mixed battery streams. Part of this also involves assembling the electrochemical cells used in one of these processes.

The role of TNO: developing and scaling up electrochemical processes

Within the CRM Lion project, TNO focuses on recovering materials from black mass (WP3). We do this by developing innovative electrochemical processes. The first step is to research dissolving critical materials in a solvent, such as water. By electrifying the method of recovering critical materials, we can reduce the use of chemicals, which lessens the environmental impact.

After we have optimised the processes for recovering the critical materials, our goal is to scale up and, at a later stage, bring them to market. In doing so, we look not only at technical feasibility but also at economic aspects, such as how profitable this method is.

Our aim is to demonstrate with models that these methods are more sustainable than current methods for battery processing. We are also working on technologies that better fit the capabilities of Dutch industry, such as flexibility in power consumption and minimal emissions to the environment.

Everything about critical raw materials

Discover how TNO is contributing to greater autonomy in critical raw materials. From strategic insights to innovative technologies: read how we are increasing security of supply and making Europe less dependent.

Building on the project for a strong battery ecosystem

Project CRM Lion builds on insights from an earlier TNO project: Green Transport Delta-Electrification (GTD-E). While GTD-E mainly focused on mapping the state-of-the-art battery recycling technologies and the pros and cons of certain techniques, we are now actually working on setting up new, more sustainable, and future-proof technologies.

Together towards a circular chain

Would you also like to contribute to the development of a circular and sustainable battery chain in the Netherlands? Or would you like to know more about the latest insights and technologies? Then contact our team. Together, we can accelerate the transition and ensure that the Netherlands leads the way in recovering critical materials from batteries.

Get inspired

A fossil-free 2050 is technically achievable

Temporary Special Economic Zone around Rotterdam can prevent climate delays and GDP losses

Making sustainability strategies robust and resilient in an uncertain world

Nuclear energy in our future energy system

Climate fund applications from the perspective of broad prosperity