CSI Thermal vacuum environmental calibration test-setup

- Category:

- Vacuum

- Brand:

- Acs

Description

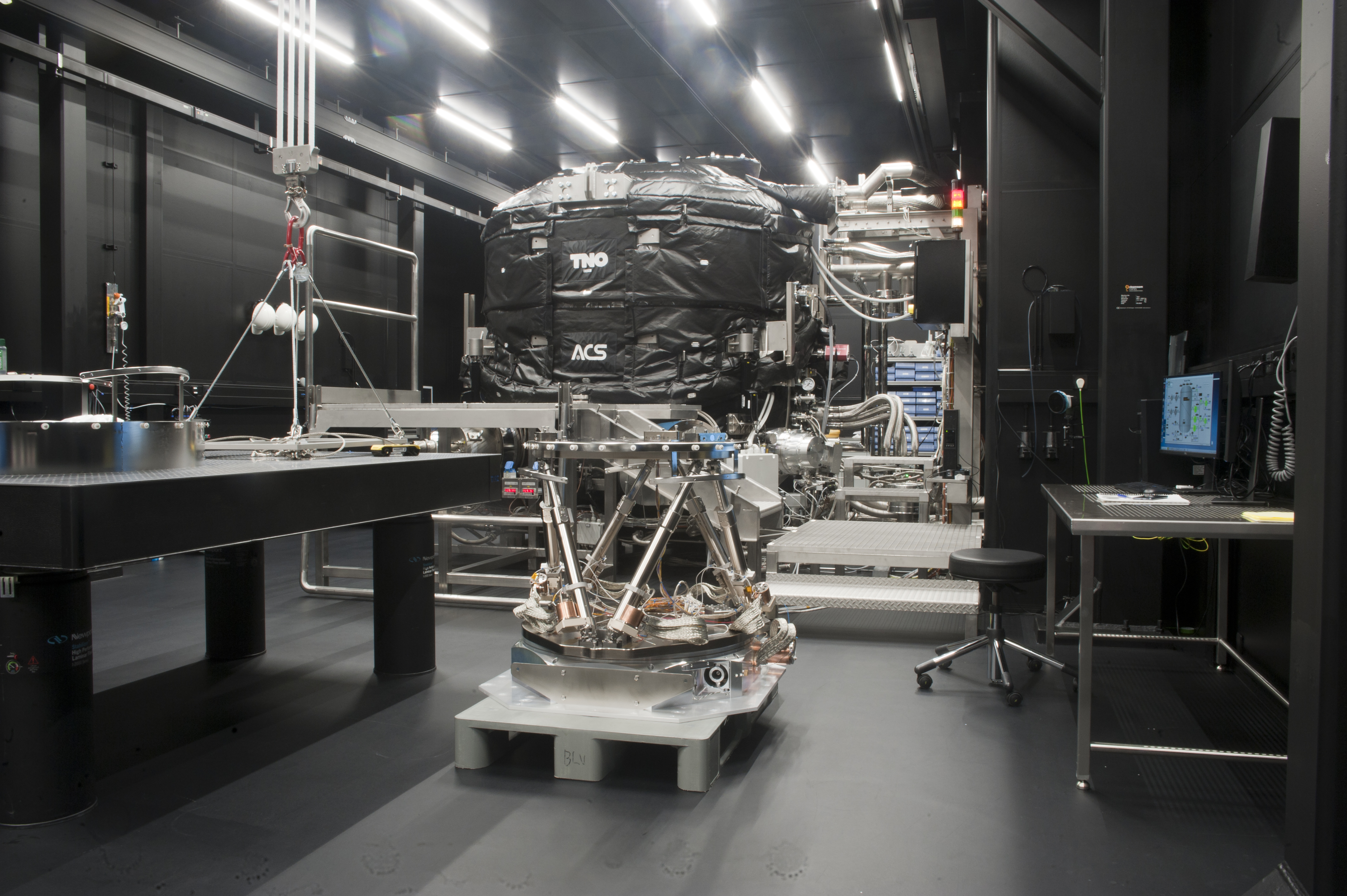

The CSI is a high end thermal vacuum test set up for calibration, qualification, and system validation of space instruments. The CSI Thermal Vacuum test set up is the most advanced thermal vacuum chamber within TNO’s Space Systems Engineering department. Built in 2022, the set up is fully designed for high precision calibration, thermal characterization, performance measurements, and end to end validation of both optical payloads and complete space systems. Thanks to its large internal volume, extreme thermal flexibility, and precision positioning capabilities, the CSI provides a unique test environment that closely matches the conditions in space.

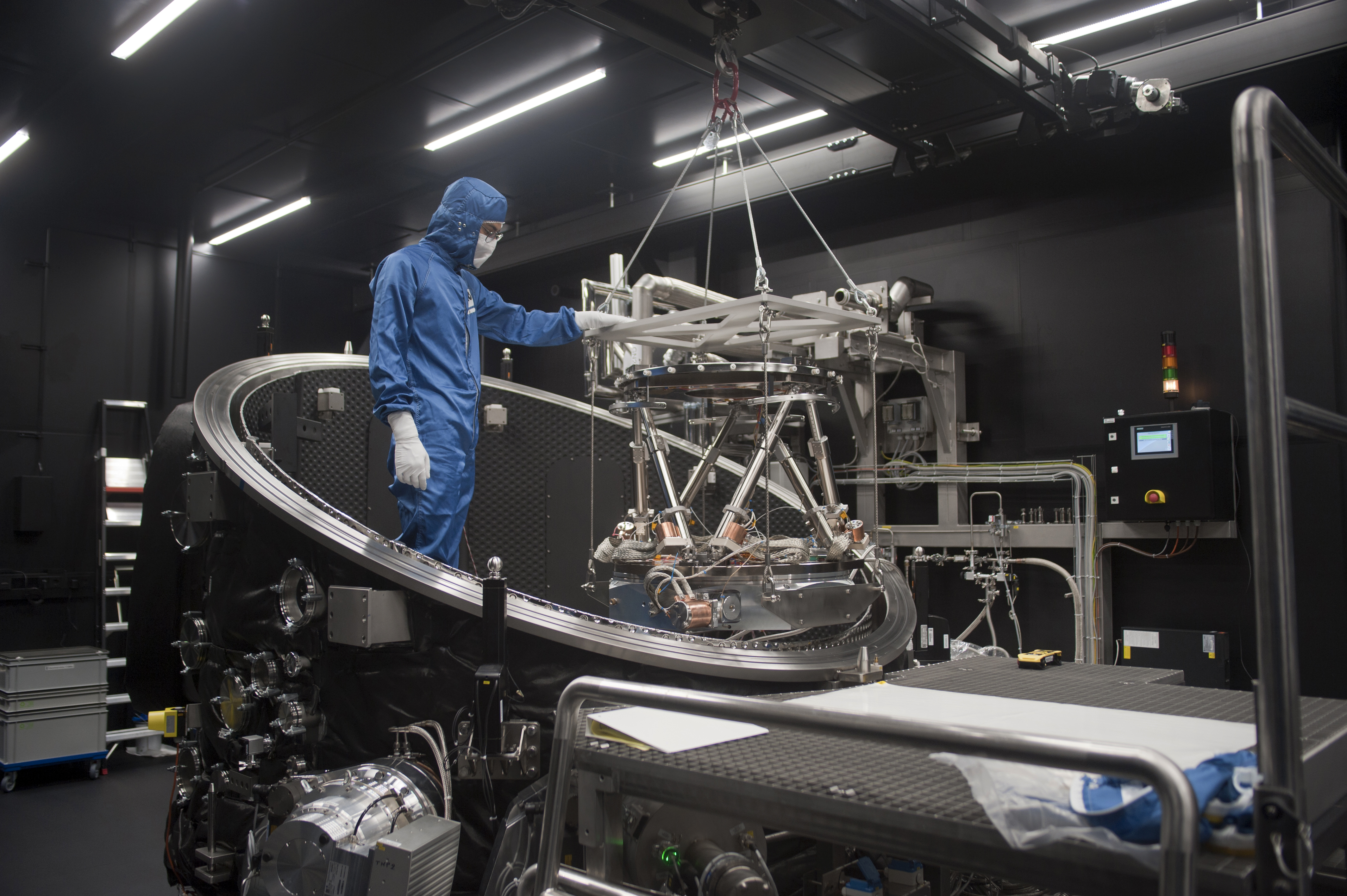

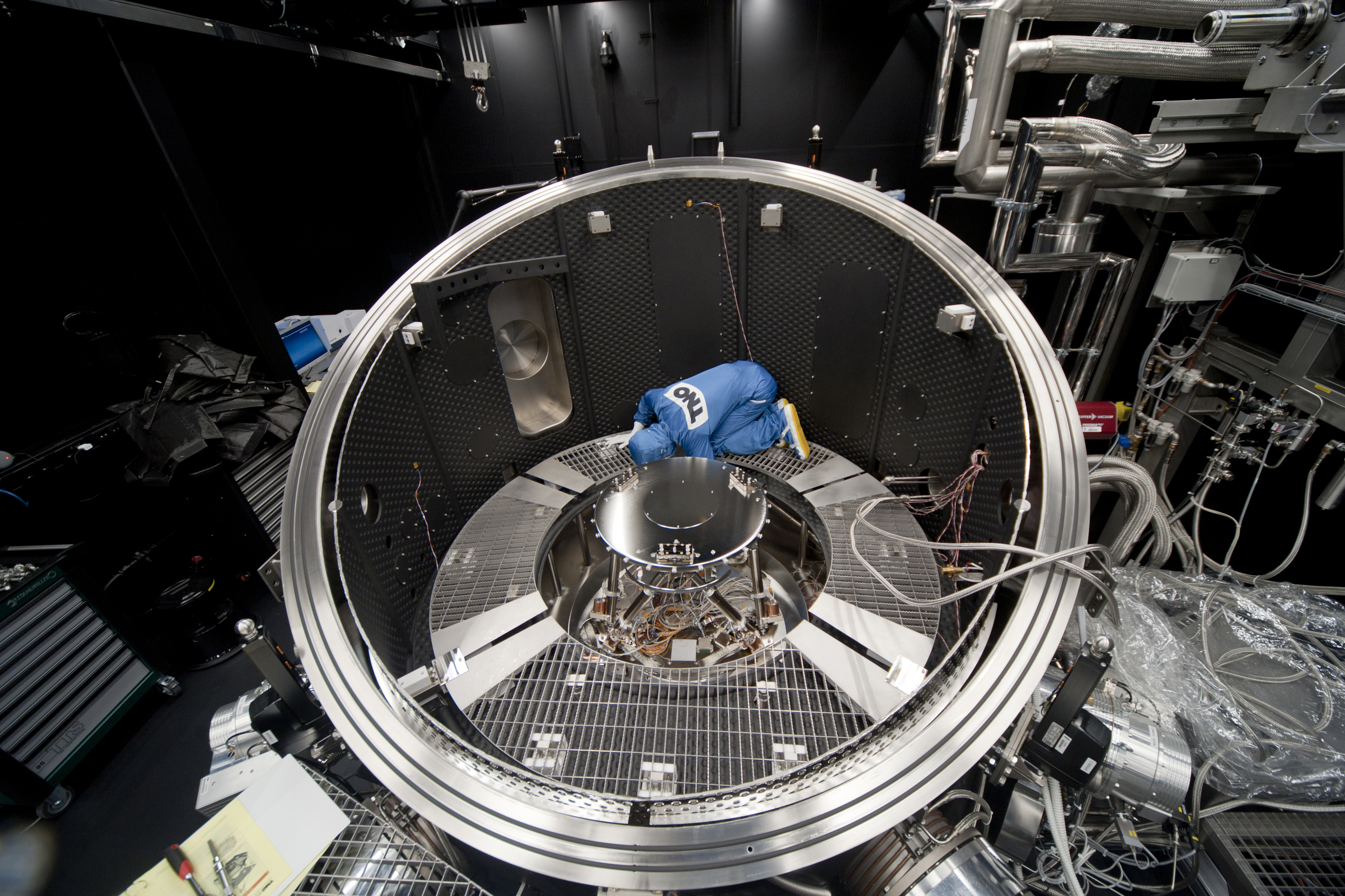

CSI stands for Calibration Space Instruments. The test set up features a top opening vacuum chamber, with the upper section lifted using an overhead crane. Combined with an internal walkway, an integrated instrument crane, and excellent accessibility from multiple sides, this set up is ideal for complex and large volume test configurations.

With two large optical windows and a vacuum compatible hexapod (six axis positioning platform), instrumentation can be aligned and positioned with extremely high accuracy in six degrees of freedom. This makes the CSI particularly suitable for optical calibrations, thermo-mechanical stability testing, and precise end to end measurements.

Additional techniques

The CSI is located in the Anthony van Leeuwenhoek laboratory at the TNO Delft site and complies with ISO Class 7 cleanroom specifications. The environment offers:

• ESD safe flooring with monitoring

• 50 m² + 20 m² of cleanroom space for GSE and preparation

• Capability for complete darkening for optical measurements

• A remotely accessible control system with configurable SMS notifications

• 24/7 emergency connection and periodic safety inspections

Applications

The CSI is used for, among other things:

• Calibration of optical instruments and sensor systems

• Functional, thermal, and mechanical validation of complete instrument assemblies

• 6 DOF instrument positioning using a high precision hexapod

• Stability testing under high vacuum and extreme temperature conditions

• Contamination monitoring via cold trap and mass spectrometer

• Automatic, reproducible calibration programs integrated with external calibration and validation equipment