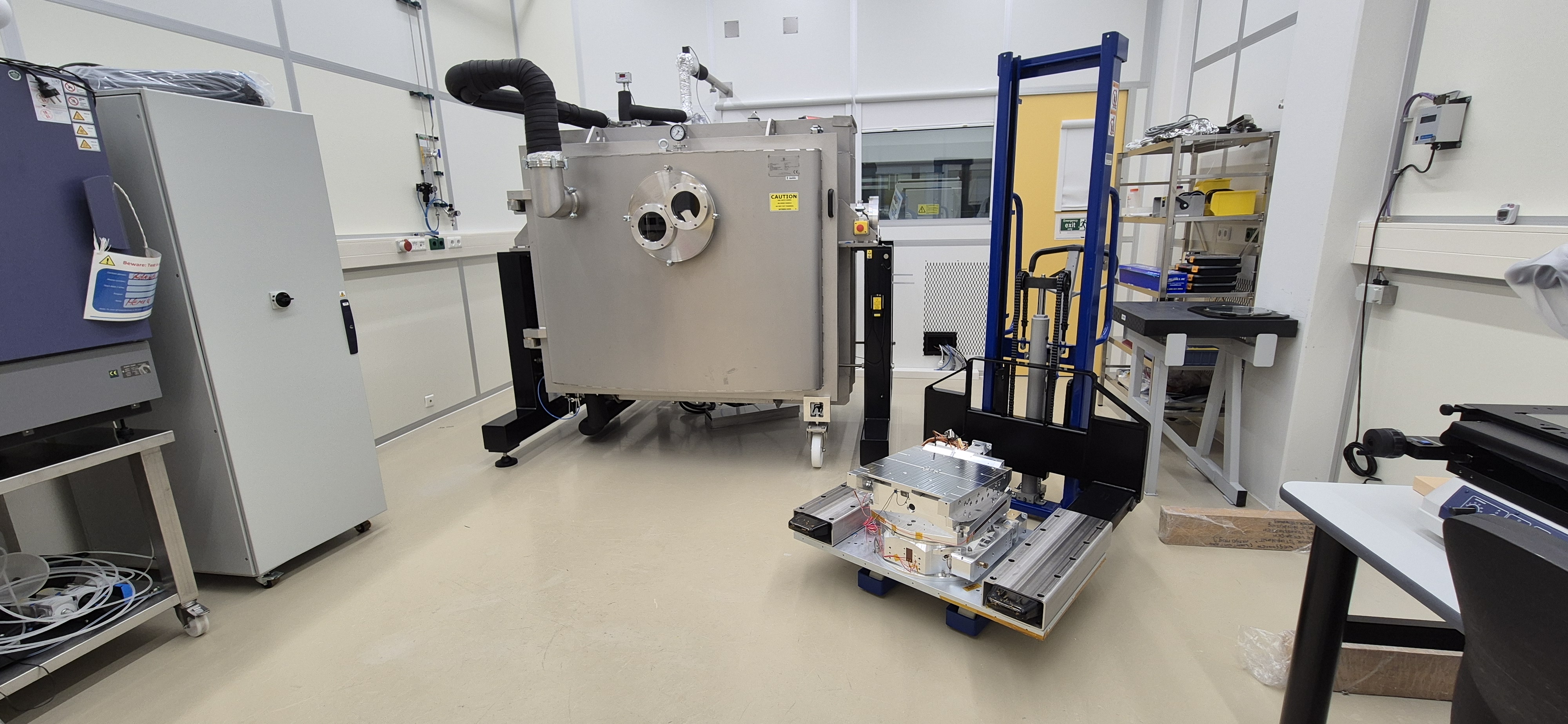

GLS Thermal vacuum environmental test-setup

- Category:

- Systeem

- Type:

- GLS vacuum chamber

Description

The GLS Thermal Vacuum test set up is a large, highly stable, and precisely controlled vacuum chamber, built in 2017, enabling instruments to be tested under realistic space conditions. This environment makes it possible to validate the performance, stability, and reliability of subsystems and complete instruments before launch.

The GLS is specifically designed for thermal and vacuum testing of both optical and mechanical space instruments. The facility supports, among other things:

• Thermal cycling and thermal equilibrium testing

• Calibration of optical and mechanical instruments

• Contamination monitoring using an automatic cold trap and mass spectrometer

• Accurate instrument positioning through integrated azimuth and elevation motions

Thanks to the high thermal stability and deep vacuum levels, engineers can reliably predict the behavior of instruments under extreme conditions.

Technical details

Technical performance

• Internal volume: 1140 (h) × 1100 (w) × 850 (d) mm

• Shroud temperature range: +100 °C (±2 °C) to –175 °C (±5 °C)

• Cold plate temperature range: +100 °C to –170 °C

• Cold finger (cold trap): –196 °C

• Vacuum:

• Mass spectrometer (RGA): 0–200 amu

Optical & technical interface

• Two optical windows (Ø 200 mm):

o Infrasil quartz

o Russian opal

• Electrical feedthroughs: extensive set of Sub D feedthroughs for various test configurations

• Professional vacuum stage with precise azimuth and elevation control

• Black coated shroud and separate cold plate for controlled thermal loading

Contamination control

• Turbomolecular pump

• Fully automatic cold finger

• Continuous gas analysis via mass spectrometer

• Holders for molecular samples for outgassing tests

Additional techniques

The GLS is located in the Anthony van Leeuwenhoek laboratory at the TNO Delft site and complies with ISO Class 7 cleanroom specifications. The environment is designed for safe and precise space qualification testing and includes:

• Class 7 cleanroom with continuous monitoring

• ESD safe flooring and ESD monitoring

• Central security system (manned 24/7)

• Active RI\&E and periodic safety inspections

• Remotely accessible control system

• Configurable SMS notifications for threshold exceedances

Applications

The GLS combines a large internal volume, high temperature stability, excellent vacuum conditions, and extensive test options. This makes the facility highly suitable for:

• Thermal vacuum testing of space instruments

• Calibration campaigns

• Performance and stability tests

• Contamination analyses

• Qualification and acceptance testing

With this facility, TNO offers an extremely clean, flexible, and reliable environment for the thorough testing of critical space hardware.