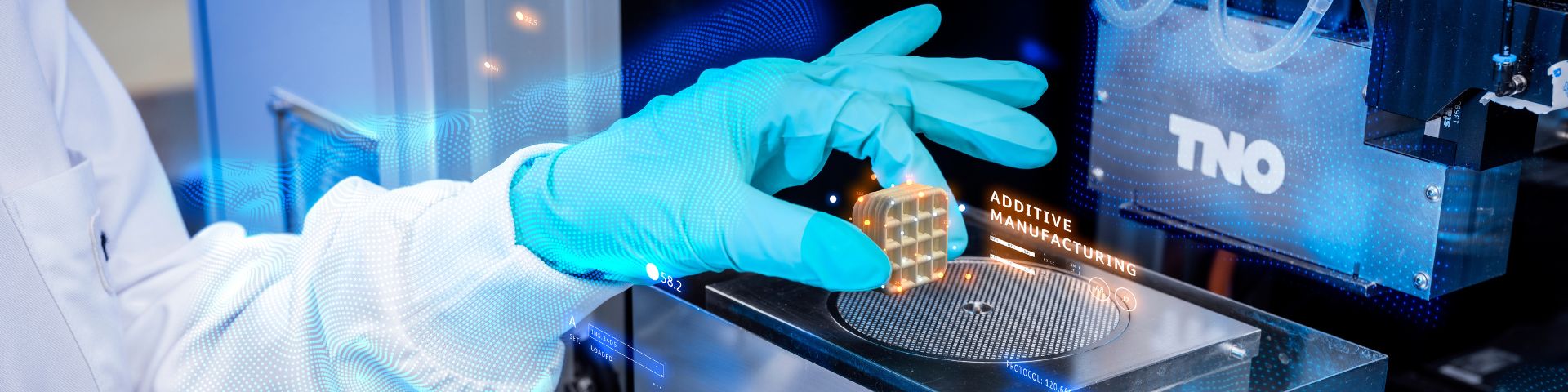

This is our time: Technology for 3D-printed food

The food industry is on the brink of major changes. Growing consumer demand for healthy, sustainable food options is driving the need for a transition to more plant-based proteins. It is essential to find alternative protein sources besides animal-based ones that can be produced efficiently, such as plant proteins and microorganisms. TNO plays a crucial role in this with the development of advanced printing technology. Together with Wageningen University & Research and companies like Royal Avebe, we have developed a 3D printer that can accelerate the transition to plant-based proteins worldwide. An innovation that allows us to create tailor-made, plant-based protein products. The next step is for companies to scale up the technology.

How we are making an impact

Food from a 3D printer?

‘In the future, plant-based proteins will be central to our food production. Companies need to innovate and deploy new technology. TNO’s 3D printing technology is key to a global scale-up.’ Bart Fischer, Business Developer at TNO

Royal Avebe is delivering the raw materials for the food of the future

‘By pooling our expertise, we can accelerate innovation. Avebe brings the ingredient knowledge, TNO brings the technology, and Wageningen University brings the protein formulas. Transforming the food production chain is simply too big to tackle alone.’ Annet Vrieling, Food Application Specialist at Royal Avebe

Time setter Emma is developing a 3D food printer

‘3D printing opens the door to countless new sources of meat substitutes. Even protein-rich products that are currently thrown away can be harnessed this way.’ Emma Munnig Schmidt, Systems Engineer at TNO