SEAMIIC: Autonomous parts handling and quality control

Additive manufacturing (AM) – including 3D printing – has the potential to be a major disrupter for the manufacturing industry. Yet AM isn’t as disruptive as it could be. The primary reason? Post-production of 3D-printed components is still prohibitively expensive, time-consuming, and slow. TNO is partnering with automation scale-up AM-Flow to offer SMEs and OEMs the opportunity to explore the potential of flexible, integrated, automated post-production in a low-cost, low-risk environment.

About AM-Flow

Through deep-tech innovation, AI-based robotics, and machine vision technology, AM-Flow aims to enhance efficiency, reduce cost, ensure consistent quality and accelerate lead times throughout the entire manufacturing process.

Meeting the need

AM is often more digital than conventional manufacturing and offers the ability to quickly produce an infinite variety of geometries on demand. However, processing such an unlimited variety of products and bridging the gap between n=1 and mass manufacturing can be a real challenge. Although many manufacturers already utilise 3D printing and digital technologies at the front end of their manufacturing processes, no company has yet found a solution for the time-consuming and costly processing of all those different parts on the back end. From cleaning the components after printing to properly sorting, inspecting, labelling, and packaging them, manual labour is still required. Processes are often slow and prone to error.

While many SMEs and large OEMs are interested in exploring high-mix manufacturing of three-dimensional parts and automated post-production, it is simply too risky for them to invest in it themselves. Setting up a fully automated post-production process – especially for high-complexity, high-mix, high-tech components – is costly and requires specific equipment setups. If a company builds such a set-up, they must first be certain that automation is right for their particular product and market.

PPP for progress

Experts from TNO Smart Industry formed a public/private partnership (PPP) with AM-Flow to help bridge this gap and enable SMEs and OEMs to explore the potential of a fully integrated and automated system in an open testbed. In this way, companies can uncover whether automated and integrated techniques can be as cost-effective, efficient, and scalable as suspected, before they invest in the equipment needed to enable it.

The Smart End-2-End Additive Manufacturing Innovation Industry 4.0 Centre (SEAMIIC) testbed will bridge the gap between advanced individual process steps and fully integrated automation. With a particular focus on hyper-efficient post-production, SEAMIIC aims to bring fully connected, Industry 4.0 solutions to SMEs that may otherwise not have the resources to explore the technology’s potential. Large high-tech companies can also benefit from the testbed to enable better business case planning and faster implementation. In addition, the data collected in the testbed will feed AI systems to make post-production processes even more effective, efficient, and scalable.

‘The digitally connected equipment and production processes in SEAMIIC make it easier to integrate new technologies, like AI, to keep systems scalable and flexible for future innovations.’

Complementary expertise

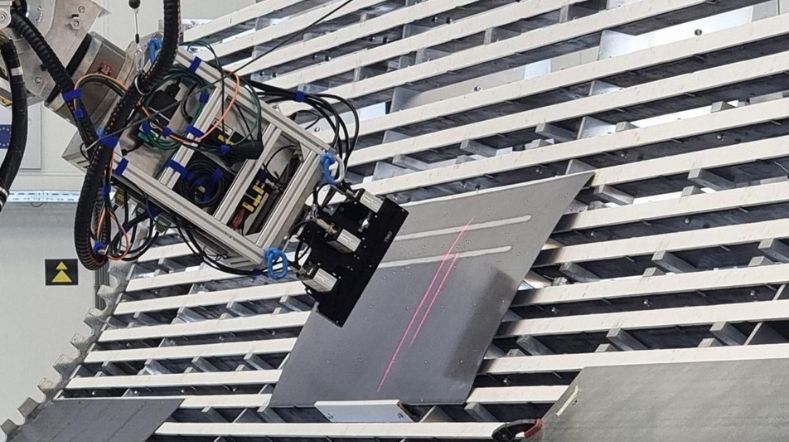

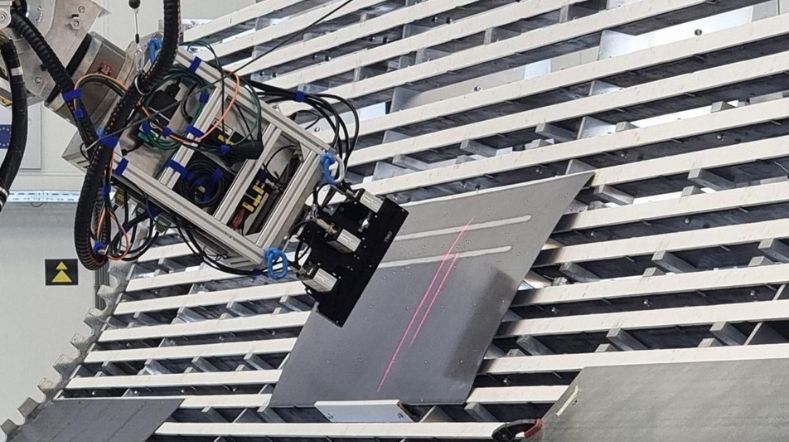

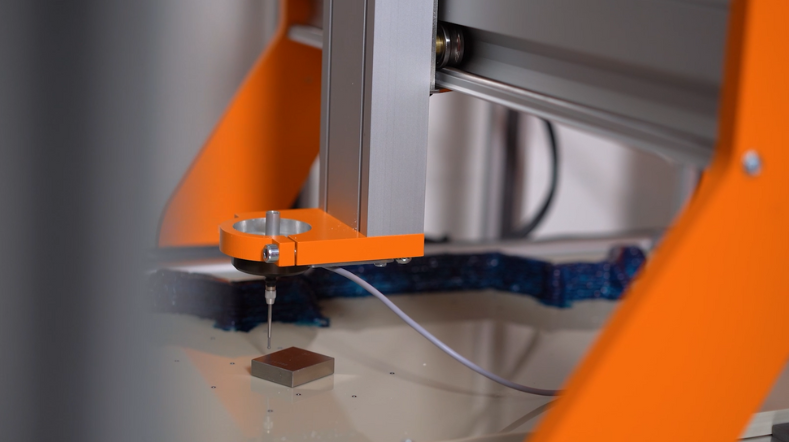

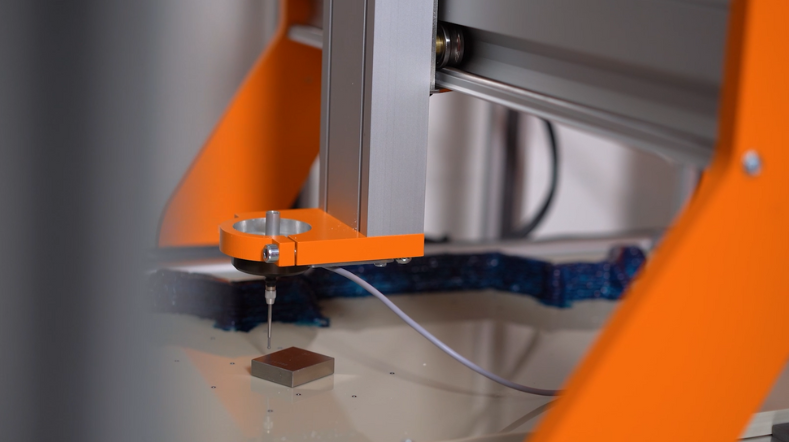

In SEAMIIC, AM-Flow brings the base technology needed to automate the individual steps of post-production: from sorting the printed parts to quality control to packaging. TNO brings smart manufacturing essentials like robotics, data and AI, smart sensors and optomechatronics that can connect the individual stations together and to outside suppliers, collect essential data for optimisation, enable the stations to communicate effectively with each other, and develop a true Industry 4.0 solution.

SEAMIIC offers SMEs and OEMs a ‘test before you invest’ opportunity to uncover what benefits integrated automation can bring to their specific processes. TNO is also exploring ways to further improve AM-Flow’s inspection capabilities with 3D cameras and ultrasound technology, which would not only determine if a product has the right physical specifications, but also the structural integrity that is required – something that current systems cannot provide.

Human-centric technology

Perhaps most importantly, TNO offers its expertise in operator-centric design. In SEAMIIC, TNO is enabling the integration of instant digital work instructions, troubleshooting data, AI, and more to help operators do their work more effectively, efficiently, and at higher speed and accuracy. In this way, automation does not replace human workers, but rather makes their work much more effective and enjoyable.

After testing the solution, SMEs and OEMs receive detailed system requirements and specifications to build their own Industry 4.0 post-production system. SEAMIIC not only offers insight into how the technology can save time and costs and reduce waste, but also a glimpse into how to better utilise human workers, make their jobs more effective and less monotonous, and reduce errors through highly detailed, AI-driven work instructions and defect detection.

Beyond Additive Manufacturing

The SEAMIIC partners also see significant opportunities for companies with extensive repair and refurbishment processes. The same technology that can automate AM post-production can also be used to automate return flows. It can bring precision, speed, and accuracy to complex sorting, inspection, and distribution of replacement components and returned parts, further reducing waste and ensuring the optimisation of these often time-consuming and costly processes. The AI-enabled system and data-driven software can identify roadblocks and streamline processes for higher levels of efficiency.

In the end, SEAMIIC aims to help AM become the true disrupter that it is purported to be: by connecting the digital front-end of production to the labour-intensive back-end, manufacturers can take a significant step towards ‘dark factories’ – fully automated factories with interoperable systems that connect each member of the supply chain, acquire components from various suppliers, produce on demand, and distribute to each recipient. In particular, industries like semicon, automotive, and even defence have been identified as potential beneficiaries of this revolutionary methodology. But first, manufacturers must confirm that integrated automation is right for their specific process – something they will now be able to do through SEAMIIC.

‘Through SEAMIIC, companies can innovate in ways that give them a competitive advantage, not only in 3D-printed materials but in return flows for repair and refurbishment.’

Future focus

Made possible in part through funding from the PPS supplement scheme for PPPs from Holland High Tech | TKI HSTM, the SEAMIIC testbed will be ready to welcome interested SMEs and OEMs in early 2026. Until then, individual components of the system are being tested in operating factories to build robust data profiles and optimise the individual steps of the process.

For TNO, the SEAMIIC project is a prime example of our effort to not only strengthen existing value chains, but to also create new value chains that are sustainable, resilient, and efficient to boost the Netherlands’ position in manufacturing. TNO’s unique ability to view and analyse the entire production chain will enable SMEs to gain competitive footing and ensure that production processes in manufacturing can be scaled faster, more simply, and more cost-effectively.

Get inspired

3D Nesting: precision quality control and manufacturing efficiency

Partnering for mutual progress

TNO spin-off Scenexus secures 1.6 million euro investment

Scale up: manufacturing throughput and quality

Non-destructive inspection