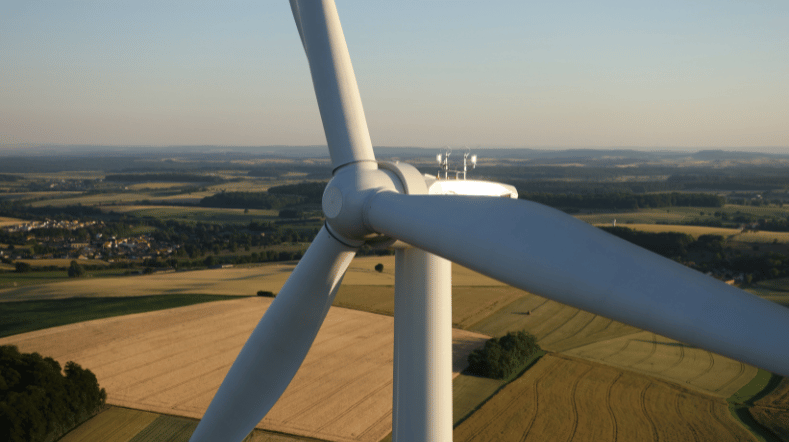

Accelerating offshore wind farms

The expansion of wind farms in the Dutch sector of the North Sea is moving up a gear. In the spring of 2022, the cabinet designated three new areas for the development of wind farms. The original target of 11.5 gigawatts by 2030 will now be almost doubled to 21 GW.

Offshore wind farms move up a gear

To achieve these ambitions, TNO is researching and developing innovative technologies and methodologies for the new generations of wind turbines and wind farms.

Our latest developments

28 resultaten, getoond 1 t/m 5

Improving wind turbine maintenance with the sensor installation robot

The robot autonomously installs sensors deep within wind turbine blades. For efficient, accurate measurements and reduced maintenance time.

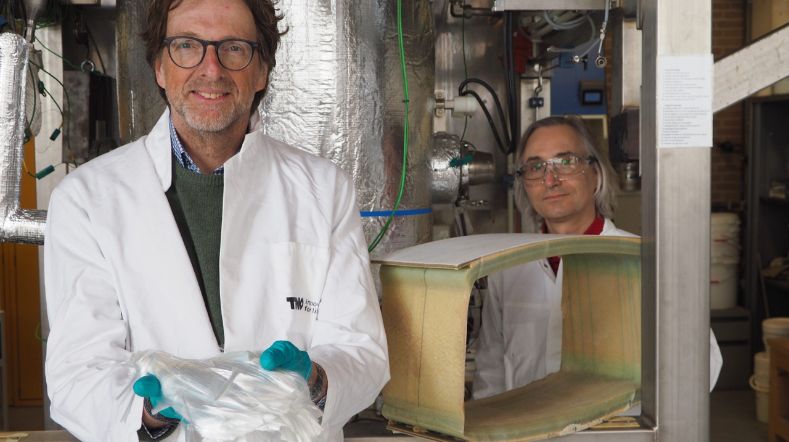

Project launched for recycling wind turbine blades

TNO research leads to better damage prediction for offshore wind turbine blades

Better damage prediction for wind turbine blades through unique weather measurements at sea

First study on public perception of wind turbine circularity