Flexible and free-form products

Food and medicine from 3D printers are well-known examples of flexible and free-form products. These products help advance human development and industry. Discover our knowledge and expertise.

More then 25 years of experience with flexible and free-form products

Flexible and free-form products are the key to pioneering technologies and applications that will create new value chains and improve people's overall health.

Our latest developments

9 resultaten, getoond 1 t/m 5

TNO spin-off AIKON Health secures €1.2 million seed round to advance remote heart failure monitoring

AIKON Health, TNO’s spin-off in digital health, raises €1.2 million in seed round!

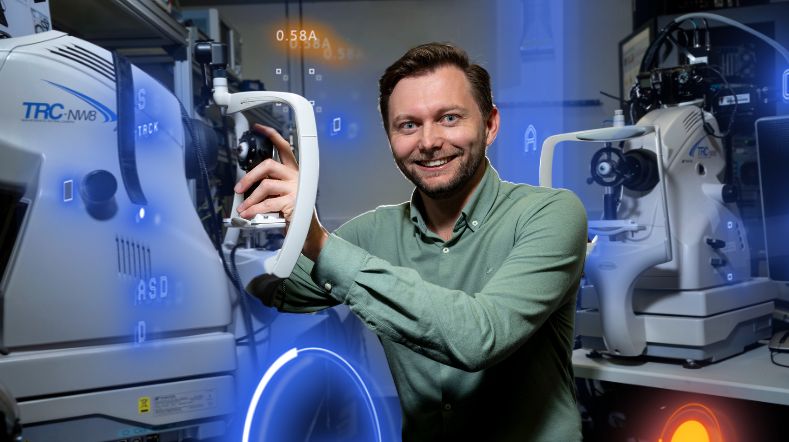

Developing accurate and inclusive medical devices

3D printed food: the future of personalised nutrition

TNO develops ultrasound patch for organ monitoring

Time setters: wearables that monitor your health