Time setters: Smart windows bring climate-neutral living a step closer

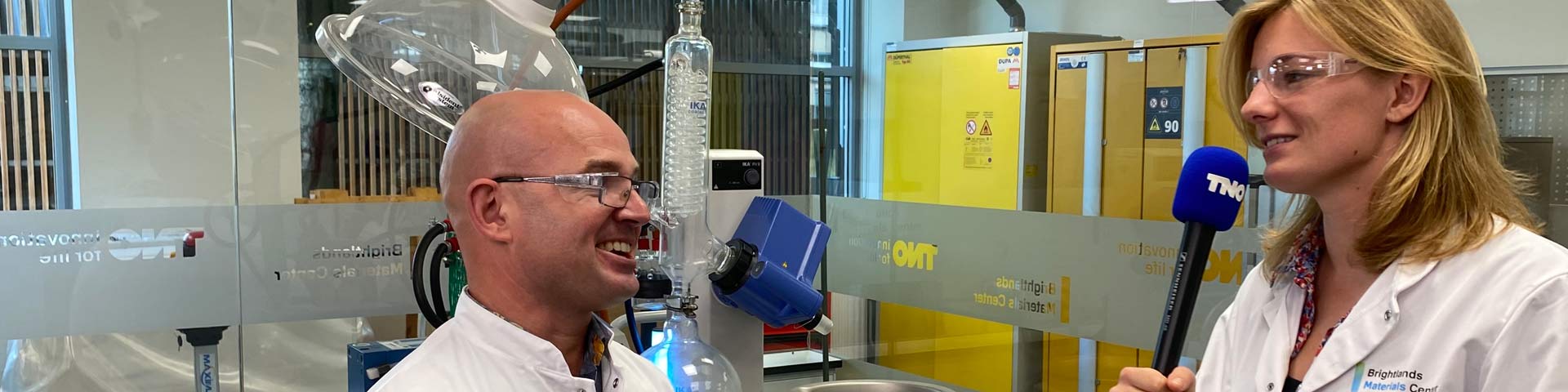

At TNO, we make a mark on our time. In this series, you’ll meet the TNO employees behind the innovation – the time setters. What do they do exactly and what impact does their work have on society? In this episode, we talk to time setter Roberto Habets, Lead Researcher, about how smart windows bring climate-neutral living one step closer.

Innovative technology for climate-neutral living

The built environment in the Netherlands currently accounts for 40% of energy consumption and almost a third of carbon emissions. The more than 7 million buildings in the Netherlands need to become substantially more sustainable to be climate-neutral by 2050. To meet this target, we may soon use another innovative technology in addition to insulation, solar panels, and heat pumps.

TNO is working on SunSmart windows that block solar heat in summer, while letting it through in winter. In this way, they help regulate the temperature in your home, thus reducing the use of air conditioning and heating. This innovation could save an average household around 400 kg of CO2 annually and hundreds of euros on energy bills.

Cool in summer, warm in winter

Electrically controlled windows already exist, but that technology is expensive and makes windows switch between lighter and darker shades. The ultimate solution, an affordable smart window with invisible integrated temperature regulation, is at an advanced stage. TNO’s SunSmart window features a special thermochromic coating that can switch between transmitting and blocking solar heat at a defined switching temperature.

'In winter, the solar heat warms your house; in summer the solar heat is kept out and your house stays cooler.’

Roberto Habets, Lead Researcher at TNO-Brightlands Materials Center, explains how it works: ‘If it’s warmer than 20 degrees Celsius outdoors, the thermochromic coating blocks the sun’s heat, keeping it cooler indoors. If the outdoor temperature drops below 20 degrees, the coating switches automatically to allow the sun’s thermal radiation to pass through. The interior of the home then warms up.’

In search of the ideal coating

Habets and his colleagues at TNO-Brightlands Materials Center began their research on thermochromic windows in 2017. ‘We knew from scientific literature that vanadium dioxide possesses thermochromic properties. At 68 degrees Celsius, this material can switch between transmitting and blocking solar heat.’ To achieve the desired switching temperature of 20 degrees Celsius and optimise the optical characteristics of the window, Habets and his colleagues had to mix vanadium dioxide with other ingredients.

This is a time-consuming process: ‘In 9 cases out of 10, you don’t get the desired improvement right away. But you become a little wiser with every step,’ Habets says. Around 2019, the first coatings emerged that showed promise, even if only on a 10-by-10-centimetre piece of glass. The solution also had to meet aesthetic requirements: a transparent coating that does not change shade or colour when switched. Habets says: ‘The idea was that while the window does switch in functionality, you don’t see any of it with the naked eye. It just filters thermal radiation from the sun.’

Ready for production by 2025

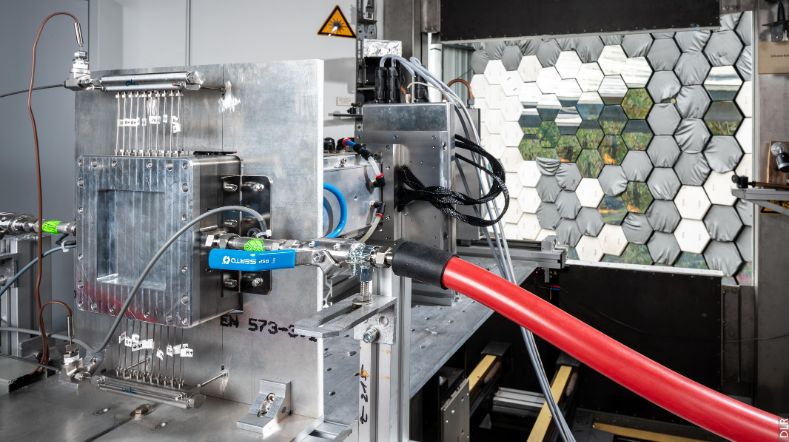

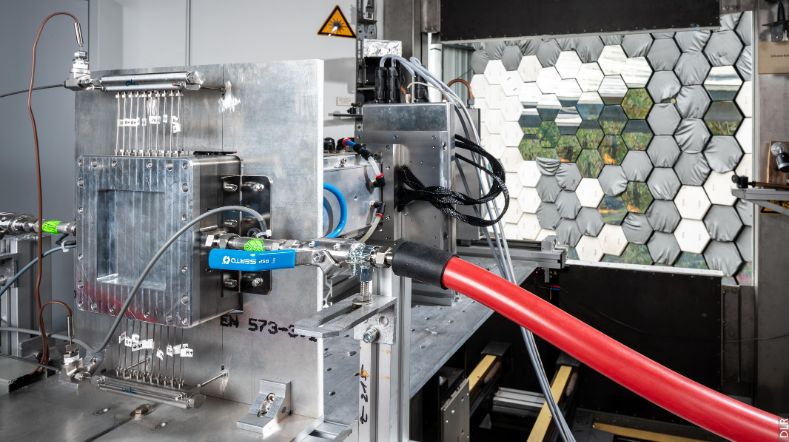

The coating’s performance has now been demonstrated, but the process is not yet ready for use in large-scale production. The next goal is to apply the coating in an industrially relevant way to a glass surface of one square metre.

For this purpose, TNO has built a special ‘pilot demonstration line’: a mini test plant equipped with technology that industry also uses, complete with a washing station, coating machine, and high-tech oven. ‘For optimum results, we need to find the ideal settings for all those processes and machines,’ Habets explains. ‘That’s a challenging development path.’ The thermochromic windows must be ready for production no later than 2025. ‘Once we demonstrate that we can produce the windows at pilot scale, the technology can be brought to a large-scale production by commercial parties.’

Fast payback

Habets expects the SunSmart thermochromic windows to have a payback period of 5 to 7 years. ‘During development, we explicitly looked for raw materials and production steps that are low in cost. The idea is that our innovation will be implemented on a large scale.’

'It’s a matter of installing the windows and you’re good to go. The coating switches automatically, without the user having to do anything.'

Based on the test results, Habets believes that an average Dutch household with a home full of smart windows will save 400 kg of carbon emissions on an annual basis. In addition, thermochromic windows can reduce annual energy bills for air-conditioned homes by around 500 euros.

Those without air conditioning benefit from keeping the house cooler in summer. ‘It’s a matter of installing the windows and you’re good to go. The coating switches automatically, without the user having to do anything. It’s an intrinsic property of the coating material. In summer and in winter, you win. In summer, your house warms up less, and in winter, the solar heat actually contributes to warming your home.’

Solar panels and hydrogen

With the smart windows nearing production readiness, Habets and his colleagues are continuing to innovate. In addition to coloured coatings for solar panels, he is currently working on a new invention based on functional coatings: active layers that can split water into hydrogen and oxygen.

‘With this technology, you can make solar panels that produce hydrogen instead of electricity,’ says Habets. This new invention may also soon find its way to market in the now tried-and-trusted pilot plant. Habets concludes: ‘Houses and offices can become much more sustainable thanks to our innovations. That’s what ultimately gives us the most satisfaction; that’s what we do it for.’

Want to know more?

If you would like to know more about our SunSmart windows, or are interested in collaborating to bring this innovation to market, please contact us.

Want to be a time setter?

Come work at TNO and make your mark on our time.

Get inspired

VoltaChem Year Event 2025

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale

Smart windows