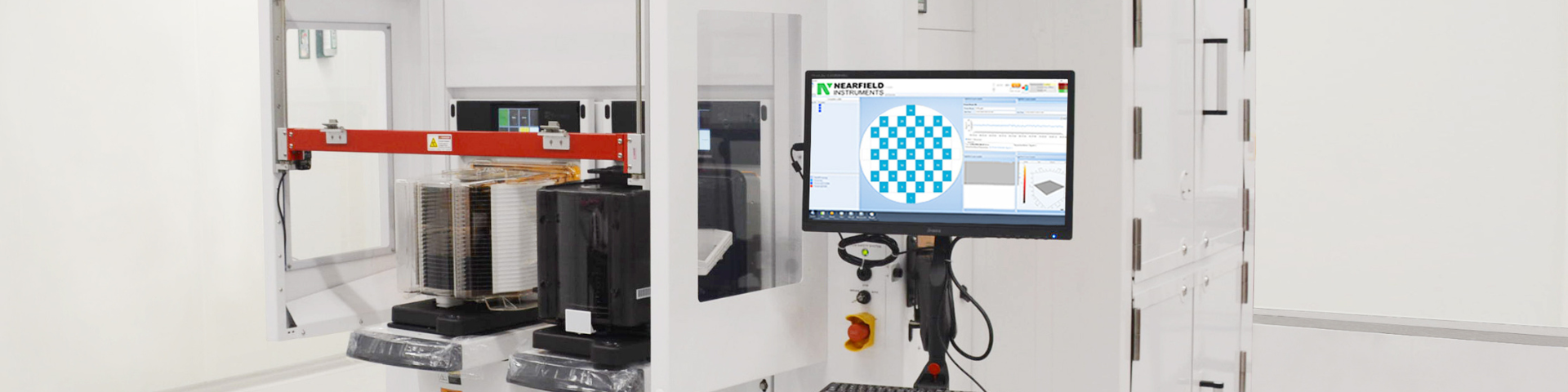

Nearfield Instruments: revolutionising chip measurement at nanoscale

The world as we know it would be unthinkable without advanced microchips. However, manufacturing ever more powerful chips brings new challenges. Measuring at the nanoscale is crucial to ensure quality without damaging the fragile structures. TNO spin-off Nearfield Instruments developed a unique nanoscale metrology machine that can measure the critical structures of microchips in the manufacturing process.

Innovation at the nanoscale

Nearfield's metrology machines use highly precise AFM probes that operate at the nanoscale. They measure changes in atomic force fields without touching the surface of a chip. Additionally, they can use sound waves to ‘see’ through multiple chip layers, creating a three-dimensional image of the chip structure. This enables manufacturers to detect defects early and improve production efficiency.

From vision to global breakthrough

The story of Nearfield Instruments started with Hamed Sadeghian's vision. After earning his doctorate at Delft University of Technology, he joined TNO and developed technology to measure microchips at nanoscale. Existing methods were either too slow or caused damage. The idea was clear: create a fast, non-invasive metrology solution for chip manufacturers.

Supported by a multidisciplinary TNO team, the first prototypes were developed. The result: Nearfield’s QUADRA machine, capable of scanning the smallest chip structures with unmatched speed and precision.

'The kind of equipment we make does not involve a one-off €1 million investment, but multiple rounds involving hundreds of millions. Yet if we were to succeed, then not only the financial reward would be huge, but we would also make a big impact on society.'

Impact on the semiconductor industry

Nearfield’s machines offer an unparalleled combination of speed, precision, and non-destructive metrology suitable for probing the best chips and expected to play a key role in testing new microchip generations. This is crucial for the semiconductor industry, where manufacturers constantly strive for higher yields and more efficient production processes. Major players such as Samsung recognise the strategic value of Nearfield’s technology and have become key partners.

Why chip manufacturers are enthusiastic about the Nearfield machine

An EUV machine from ASML produces complex chips that can consist of hundreds of layers. For chip manufacturers, it is vital to know whether all those structures are correctly positioned on the wafer. Ideally, this should be checked by high-speed sampling during production, without the loss of chips. Existing equipment was either agonisingly slow or caused damage. Nearfield now fills this gap in the market. Their machines operate at the nanoscale and are deployed during chip production to perform rapid, random measurements without damaging wafers and chips. This is unique and precisely what manufacturers of advanced chips currently require. Chip factories are extremely expensive, and if chip inspection takes too long or results in significant chip loss, it becomes difficult to maintain economic viability.

Milestone: delivery of the first machine

December 2020: the first QUADRA system, the High-Throughput Scanning Probe Metrology solution for 5-nanometre nodes and beyond, was completed. Nearfield shipped the equipment components by air to Samsung Semiconductor’s chip factory in South Korea. Assembly could only begin two weeks later, as the assembly crew flown in from the Netherlands had to quarantine due to the COVID-19 pandemic.

Nonetheless, it was a true milestone. More importantly: once the machine was finally commissioned, it delivered exactly what Nearfield had promised.

Future outlook

Nearfield stands on the verge of a global breakthrough. In the coming years, demand for advanced chips will continue to grow, driven by AI and other technological innovations. Nearfield’s expertise and patents provide a strong position to play a key role in the semiconductor industry, once again demonstrating the Netherlands’ strength in innovation, poised to capture much of this global market with billions. All indications point to this Dutch scale-up and TNO spin-off playing a vital part in measuring and checking the latest-generation chips.

With its revolutionary technology, Nearfield Instruments contributes to more efficient and sustainable chip production, which is essential for global digital and technological progress.

Impact

Nearfield Instruments shows how combining vision, perseverance, and technological excellence can transform a high-risk idea into a global success. This topic is part of an impact story. View the full impact story via the link below.

Get inspired

Airbus and TNO demonstrate secure laser link between aircraft and satellite

Globally relevant success: Airbus and TNO achieve new heights in optical communication

State of Dutch Tech 2026: The Netherlands must dare to scale at a global level

New blueprint helps organisations share data reliably

Province Noord-Brabant, TNO and partners join forces on cybersecurity