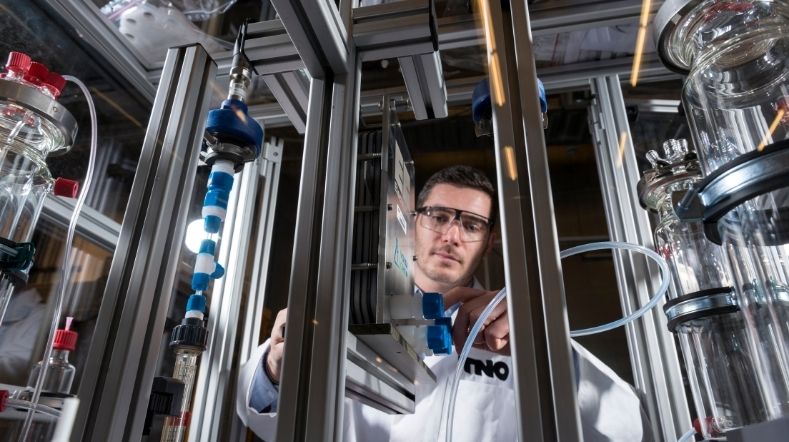

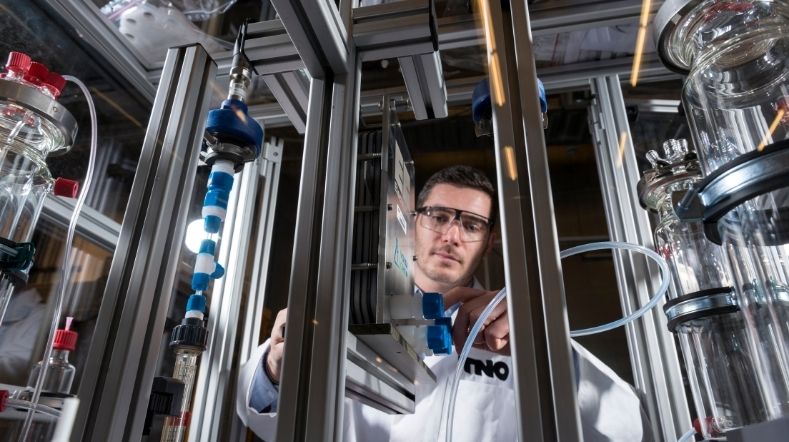

HyPRO: the road to cost-efficient green-hydrogen production

Status project

2024 - present

In cooperation with

Eleven universities, five universities of applied sciences and forty companies.

If we are to make the transition to a fossil-free energy supply, green hydrogen produced from renewable sources is indispensable. Producing this hydrogen using electrolysis or plasma technology is still a very expensive process, however. Over the next four years TNO will be working with sixteen Dutch knowledge institutions and over forty companies from the Netherlands and abroad to optimise hydrogen technologies and significantly drive down costs. This will enable the Netherlands to play an important role in developing and producing materials, components, and systems for hydrogen-production technologies.

Improving the speed to market of innovations

HyPRO, funded from the GroenvermogenNL growth fund, is the largest research project ever undertaken in our country in this field. The consortium, which is being coordinated by TNO, consists of eleven universities and five universities of applied sciences, which are making more than a hundred researchers available. The industry is represented by hydrogen users and producers, as well as by component developers, stack and system manufacturers, and system integrators. Of the 41 companies involved, eighteen have their headquarters outside the Netherlands. International collaboration is crucial if we are to accelerate the development of hydrogen-production technology. Companies from the UK, Italy, Denmark, France, Germany, Brazil, Japan, and the US are contributing financially and in kind to the consortium. Seventeen promising startups from our country are also participating. This means that the entire hydrogen-production and use chain is involved. This should ensure that innovations are embraced by the market much faster.

Optimising technologies

The consortium is focusing on optimising the four common electrolysis technologies AEM, PEM, alkaline, and SOE, as well as plasma as a relative newcomer. Although alkaline as a technology has been around for about a hundred years, there is still a long way to go to perfect it. The other three technologies also each have their own obstacles and imperfections. In the case of alkaline electrolysis, flexibility in particular is the major challenge. The proton-exchange-membrane (PEM) electrolysers widely used in Europe contain PFAS components, or fluorine compounds. Here, the focus is on working with companies to make fluorine-free membranes using new technologies and materials. Solid oxide electrolysis (SOE) is the only technology that functions at high temperatures, which makes the process very efficient, but electrolyser components are subject to rapid wear and tear. Extending the life of components is the big challenge here.

Getting ready for market

TNO previously achieved a breakthrough for PEM electrolysers by reducing the required amount of iridium, an increasingly scarce raw material, by a factor of two hundred. The ambition is to further develop this technology as part of the HyPRO project, together with companies from the value chain, and make it market-ready. Intensive collaboration between the knowledge institutions and companies in the chain will facilitate the transformation of all the envisaged innovations into concrete products and processes much more quickly.

Promising startups

Besides the established parties in the consortium, an important role is also being played by almost twenty Dutch startups, each of which has great ambitions to make its products a success. Their chances are enhanced thanks to the collaboration with the knowledge partners, which allows them to have their innovations tested, but also thanks to short lines of communication between suppliers and manufacturers within the consortium. This will enable Dutch startups to achieve technological breakthroughs and continued growth. HyPRO is about strengthening our country’s knowledge position in hydrogen technology and functions as a breeding ground for new business activity and innovative products.

- Knowledge organisations: TNO, Utrecht University, Leiden University, TU Delft, University of Groningen, Maastricht University, TU Eindhoven, Radboud University, University of Amsterdam, University of Twente, Differ, Wageningen University, Saxion University of Applied Sciences, Avans University of Applied Sciences, Fontys University of Applied Sciences, HAN, Hanze University of Applied Sciences Groningen.

- Companies: Total Energies, Shell, LyondellBasell, Johnsons Matthey, Braskem, RWE, Vatenfall, Ionbond, Hauzer, Veco, BASF, Teijin, Bosch, SolydEra, TOPSOE, FEV energy, Sairem, Bosal Group, Eneco, VDL, PRODRIVE, Sitech, I-Qatalyst, TSG Group.

- Dutch startups: VS Particle, Powall, SALD, SparkNano, Nano Hybrids, NEWES, AVOXT, Circonica, Battolyser Systems, Dr Ten, HyET E-Trol, On2Quest, Adsensys, Fluidwell, HyStream, ELEXEL.

Get inspired

Energy infrastructure and transport

The North Sea as Europe's energy heart requires smart choices

Tomorrow’s hydrogen production and infrastructure: building towards a secure and robust energy system

World Hydrogen Summit 2025

Scaling-up electrochemical technologies for renewable ethylene production