Biobased Building Materials Innovation Centre

With the Biobased Building Materials Innovation Centre (BBMIC), TNO offers construction partners the knowledge and facilities to scale up the production of circular and biobased building materials into promising products to make construction CO2-neutral.

Why BBMIC?

To achieve CO2-neutral construction, the construction sector faces the challenge of using biobased and circular materials on a large scale. Innovative building materials produced from residual wood and fiber crops are often still in an experimental phase. In the market, there is extensive knowledge of raw materials, production processes, and building requirements, but these are not always present within the same party.

Additionally, there is often a lack of resources to invest in costly production facilities, and the risk of disinvestment is high. Therefore, for market acceptance and validation of building requirements, innovative products can be produced and applied on a limited scale at the BBMIC.

How does the BBMIC help with these challenges?

With the BBMIC, TNO supports producers in the development process: from raw material to building product. TNO's expertise makes it possible to produce on a scale that is attractive to the construction sector. This helps demonstrate market potential and reduces investment risks.

The innovation centre offers partners advanced facilities and expertise for the development and pilot production of biobased building products and systems. These products and systems must meet building physics and structural requirements.

Before producers invest in costly machinery, such as a fibre press, the BBMIC offers the opportunity to fully test and optimise the process.

Additionally, the BBMIC has equipment to determine material specifications. Complementary the existing TNO Building Innovation Laboratory tests and validates prototypes, providing valuable feedback for further development.

TNO invests ahead of the market, with a broad scope and without commercial interest.

What core expertise does the BBMIC offer?

TNO focuses on four technology lines:

(Waste) wood from demolition projects is fully scanned in 3D with an X-ray CT scanner for dimensions, density, and metal positions to determine potential reuse. After the CT scan, robots (in development) remove the remaining metal and wood moisture is measured. The wood is then sawn and finger-jointed. The wooden parts are planed on four sides and glued with a vacuum press into new window frame or wood for making doors.

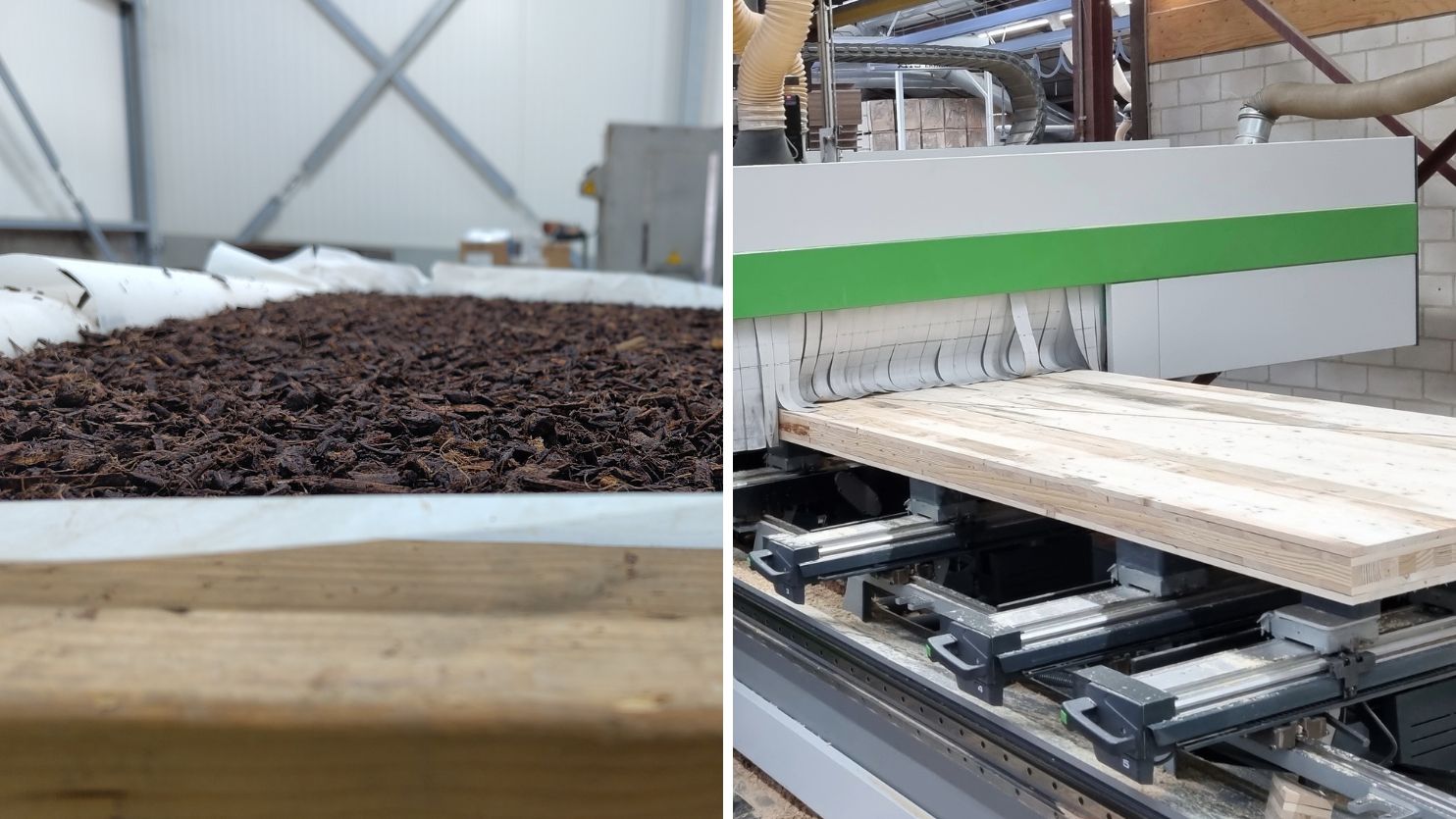

Unused pallets are dismantled and made nail-free. The pallet wood is sawn, finger-jointed, planed, and glued into CLT elements. Elements up to 8 x 3 meters with a maximum thickness of 40 cm can be produced. In the CLT elements, the pallet wood can be combined with, for example Dutch softwood in the distinct layers. These elements are further processed into, constructive prefab floors and walls using a CNC milling machine.

Various fibres, such as those from pepper plants, branch wood, or waste wood, are examined for their adhesion characteristics into sheets. Additionally, suitable, preferably biobased, adhesives are explored. It is also investigated whether pressing without adhesive is possible under extremely high pressure and temperature.

TNO is working on an extrusion or pultrusion line to mix wood fibers and create a new product. Additionally, it is being investigated whether CLT elements can be made with biobased sheets and/or integrated biobased insulation, so called Hybrid CLT.

Who could benefit from the BBMIC?

- Start- and scaleups with innovative circular and biobased products: They can work on scaling up and a successful market introduction without large investments or risks.

- Established suppliers: Companies that want to add a biobased product, such as circular CLT, as a special to their range but do not have suitable production facilities for small series can have trial batches produced at the BBMIC.

- New timber builders: Prefab producers who want to reduce the environmental performance of buildings by using biobased materials can collaborate with the BBMIC.

- Providers of residual waste: Organisations looking for a more sustainable and valuable alternative to waste combustion. The BBMIC investigates how secondary wood or horticultural waste can be upgraded into high-quality building materials.

Want to collaborate with TNO?

Discover how TNO can help turn your raw material or concept into a promising and scalable biobased building product. Together, we overcome obstacles that stand in the way of a successful market introduction. Partners can collaborate within the innovation centre in three flexible partnership ways:

- Partners can submit a specific research question to the BBMIC that they want an answer to. For example, to optimize a production process or to meet a product's relevant requirement.

- A partnership with TNO can also involve working together on a project in the BBMIC.

- Additionally, partners can independently use the facilities in the BBMIC.

Get inspired

Industrial and conceptual construction

Reliable Structures

Building materials

Building Materials and Structures

Western North Brabant becomes hotspot for biobased building blocks for the construction industry