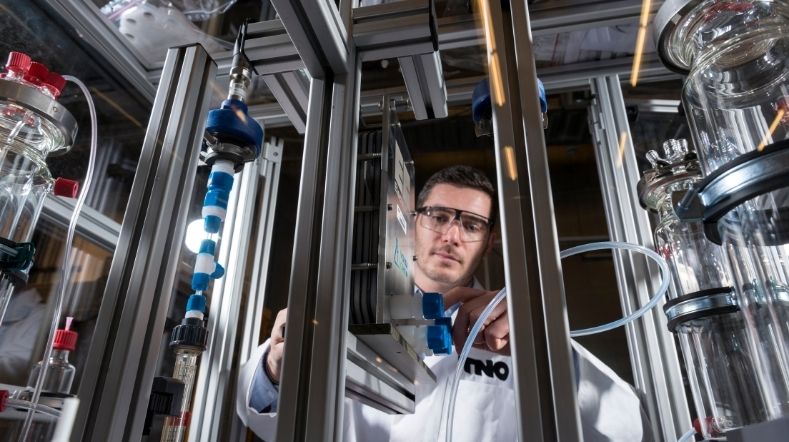

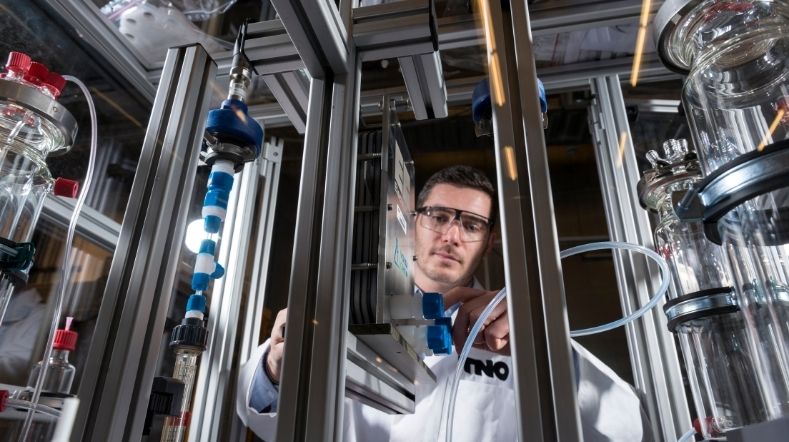

Carnot lab accelerates sustainable industry

Achieving the climate objectives in industry requires more research and development into industrial heat technologies. More than 80% of industrial energy consumption is related to the use of heat, which could prove beneficial on the way to a sustainable energy economy. The Carnot lab is taking up this challenge. This heat lab in Petten offers companies the unique opportunity to further develop industrial heat technology on a small and large scale together with TNO.

Industrial high-temperature conditions

The Carnot lab is a facility where TNO, in cooperation with the industry, develops concepts for sustainable industrial heat management and leads the way towards implementation. This involves technology for heat pumps and storage, concepts for residual heat conversion and direct electrical process heat (Power2Heat). The technology is being developed for relevant industrial (high-temperature) conditions. The Carnot lab facilitates the technology development by creating the right conditions at different scales, from lab scale to pilot installations, at up to 2 megawatts (MW) of thermal output. The lab contains state-of-the-art measuring equipment and software models to support the technology development.

This facility has been made possible by a subsidy from the Ministry of Economic Affairs and Climate Policy.

Knowledge, technology and application

TNO experts have in-depth knowledge of (industrial) heat pump and storage technology, application in industrial processes and geothermal energy. The knowledge institute also cooperates with other knowledge institutes and universities. In the Carnot lab, knowledge, infrastructure and technology development come together in an easily accessible manner. It is the gateway to knowledge and infrastructure for all heat conversion and storage technology related developments.

Partner for industrial sustainability

TNO has in-depth knowledge of industrial heat management and an ability to develop and test technology in the Carnot lab for a wider range of conditions than is possible in an industrial environment. This makes TNO the perfect partner for the manufacturing industry that wants to market technologies and for end users that want to make their heat management more sustainable. Together with partners, TNO researches and develops new technologies and concepts and helps to put them into practice. This will enable Dutch industry to make the transformation towards a CO2 neutral industry in 2050. Dutch industry can also lead the way in this respect and distinguish itself in the global market with innovative products.

Get inspired

Energy infrastructure and transport

The North Sea as Europe's energy heart requires smart choices

Tomorrow’s hydrogen production and infrastructure: building towards a secure and robust energy system

World Hydrogen Summit 2025

Scaling-up electrochemical technologies for renewable ethylene production