Biorizon makes chemical industry more sustainable with bio-aromatics

At the Biorizon research centre, we are developing new technologies for bio-aromatics. Our goal? To enable the commercial production of bio-aromatics starting in 2025. This will reduce the carbon footprint and make the chemical industry more sustainable. Find out more about our approach, the advantages of this innovation, and the various collaboration opportunities.

Aromatics are essential

Aromatics, or aromatic compounds, are important building blocks for the chemical industry. As many as 40% of all chemicals are aromatic in nature. Aromatic molecules add essential functionality to products such as plastics, resins, and coatings. For example, thermal stability and UV resistance.

Currently, the chemical industry still uses fossil-based aromatics, because commercially available renewable aromatics do not yet exist. That is why we set up shared research centre Biorizon with the Flemish research organisation VITO. In this research centre, we are working on innovative, sustainable solutions for the chemical industry. By doing so, we are reducing the carbon footprint.

Curious about how this works? Watch Biorizon's introduction video.

Chemical building blocks

We tested ideas and determined which technology developments were suitable for realising bio-aromatics. In consultation with the chemical industry, the Biorizon team determined the most technically and economically interesting routes and products. We started with technology development in the lab following a sugar-based route and a thermochemical route.

Sugar-based route

The sugar-based route consists of two steps. In the first step, we make furans – widely applicable platform molecules – from industrial sugars. These sugars are emphatically not in competition with the food chain. They are, for example, residual products from sugar refineries or from the wood processing industry.

In a second step, we convert these furans into a wide range of functionalised bio-aromatics. To do this, we have developed special processes that enable the production of bio-aromatics with a very high purity and yield.

The chemical industry then processes these bio-aromatics into existing and new high-quality materials. For example, coatings, polyurethane foams, and various types of plastic. This sugar route produced the spin-off Relement in 2020. Relement focuses on the production and marketing of first-generation bio-aromatics, for application in coatings, amongst other thing.

Thermochemical route

The thermochemical route on the other hand is based on pyrolysis and (low temperature) gasification, with which we produce aromatics from biogenic waste streams. These processes enable the production of sustainable bio-aromatics as an integral part of biorefineries.

The focus is on cost-effective ways to produce bio-aromatics as a co-product alongside other chemicals, transport fuels, electricity, and heat.

We are also developing process routes for the use of lignin as a sustainable, aromatic resource. (Lignin is one of the important components of woody biomass and agricultural waste streams). Finally, we are researching the recovery of aromatics from plastics using chemical recycling.

The Biorizon Shared Research Centre works with the entire value chain on the technological development of aromatics based on renewable resources.

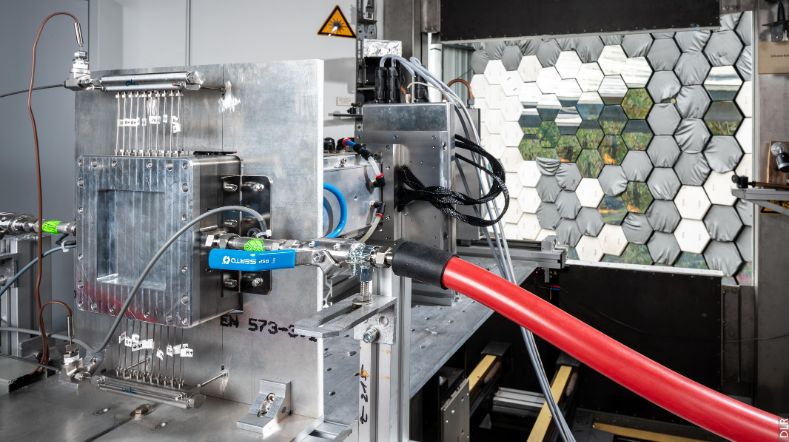

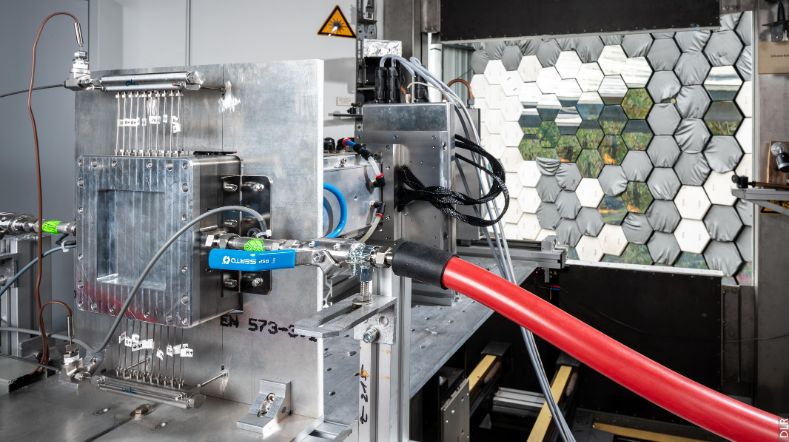

Scaling up technology concepts

Making these processes work in a continuous process on a commercial scale requires the necessary expertise. Through close collaboration, our process technologists and organic chemists were able to translate the lab's chemistry into pilot facilities. This allows us to produce bio-aromatics on a kilogram scale for industry.

For instance, in the BIO-CAPPP project, we collaborate with companies, experts, and students on renewable aromatics for commercial production.

In the coming years, we will use this expertise to develop and scale up a next generation of technology concepts. We will also scale up the technology concepts already developed to demo facilities with a technology readiness level (TRL) of 6/7 and a production capacity of 50 to 100 tonnes per year.

Benefits of bio-aromatics

With Biorizon, we are developing routes to bio-aromatics with exactly the same molecular structure as their fossil counterparts (drop-in aromatics). We are also developing new, innovative bio-aromatics. In addition to gains in sustainability, these innovative bio-aromatics have another potential benefit.

Because we start with biomass as a resource, these aromatics have a slightly different structure than aromatics made from fossil resources via conventional petrochemical processess. This is interesting, because it allows a manufacturer, for example, to create improved features in high-end products. Examples include better UV resistance, scratch resistance, more gloss in paint or greater flexibility for foams in chair seats.

Opportunities

It is precisely the various technology options that make it interesting to participate in Biorizon. For example, we can develop technology for drop-in aromatics with exactly the same molecular structure as the petrochemical industry now makes. Or we can make new, functional bio-aromatics that traditional petrochemicals cannot produce. In our applied research, we like to collaborate with all parties in the value chain:

- the suppliers of resources, such as the wood-processing industry and the agro/food sector

- technology developers/suppliers

- the chemical industry that wants to produce or purchase bio-aromatics

- the product owners at the end of the value chain who buy the new materials

Collaboration with Biorizon?

Do you share our ambition to make the commercial production of bio-aromatics possible from 2025 onwards? And do you want to work with Biorizon on the transition to a circular bio-economy? Join the Biorizon community, see our current calls for collaboration or visit the Biorizon headquarters at the Green Chemistry Campus in Bergen op Zoom.

Get inspired

VoltaChem Year Event 2025

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale

Time setters: Smart windows bring climate-neutral living a step closer