VoltaChem for electrification in the chemical industry

The international chemical industry has a large carbon footprint. We can reduce it through industrial electrification. This helps us work towards a sustainable and CO2-neutral chemical industry. Electrification of the chemical industry mainly concerns production of fuels, (bio)plastics and fertilisers. Find out how we do it, and how we can help businesses.

Technologies for innovation

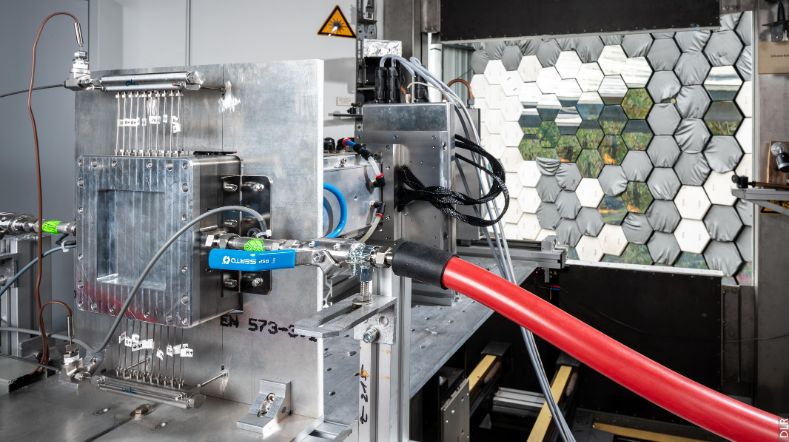

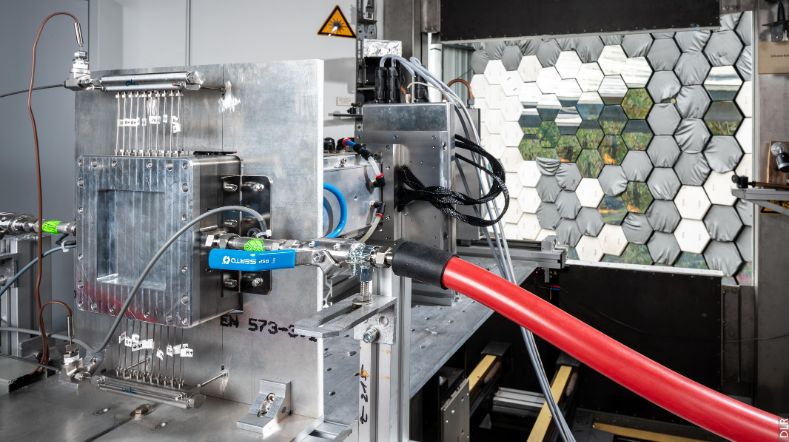

In the VoltaChem programme, we focus on the production of green hydrogen and chemical building blocks for industry from electricity. Here, we combine three technologies to arrive at an effective and efficient production system:

- electrochemistry, where we produce a product using an electrochemical cell

- plasma technology, where we use plasma for chemical conversion

- integrated thermocatalytic processes and separation steps

Challenges of CO2-neutral production

Of course, CO2-neutral production also requires energy. It’s important to use renewable energy for these processes so as to achieve fully CO2-neutral or even CO2-negative production. The basic principles of these technologies are known, but we still have major challenges to address to:

- achieve a long-term, stable operation

- achieve technological chain integration

- scale up to factory production

- bring the right value chains together

- ensure continuous improvement of the business case

Sustainable chemical building blocks

Industrial electrification is also called Power-2-X. Under the Power-2-Hydrogen name, we are working with VoltaChem on the production of green hydrogen. The focus is specifically on upscaling and improving the efficiency of existing electrolysers, such as PEM and alkaline. We use high-tech solutions, such as atomic layer deposition and web processing. Within Power-2-Chemicals we support the chemical industry and its suppliers in the development of electrochemical processes. We produce (high-quality) chemical building blocks from renewable (bio)raw materials, water and CO2. In doing so, we make use of various research facilities and an extensive network of technology providers and scientists. We focus on promising products and alcohols, such as:

- ethylene

- formaldehyde

- formic acid

- oxalic acid

- methanol

- ethanol

A faster and more efficient production

Continuous further development and innovation results in advanced electrochemistry enabling much faster and more efficient production. This makes for an interesting business case. Electrochemistry is particularly valuable here, because it results in a very pure product. No additional energy-intensive separation steps are required following the reaction. Apart from the more traditional, low-temperature electrochemical processes, we are also looking at disruptive technology. Such as plasma technology and solid-oxide-electrolyser technology. These technologies are expected to lead to breakthroughs in efficiency, enabling us to achieve the goals of a CO2-neutral chemical industry far sooner.

Business cases in the electrification industry

We also apply our in-depth knowledge to companies with business cases involving the integration of large-scale electrification solutions. We specialise in electrochemistry, plasma technology, separation technology, process technology, scale-up and techno-economic analyses. We are mapping:

- what is required to run the process within existing specifications

- the costs involved

- what equipment this will require when scaling up the technology

Locations for scaling-up research

Scaling up research is carried out at various field lab locations, such as:

- Fieldlabs Brightsite (aimed at upscaling plasma)

- Hydrohub (aimed at upscaling hydrogen)

- FLIE (aimed at upscaling CCU and power-2-heat)

Monitoring developments

Developments in both the market and in technology are moving forward rapidly. This means that constant attention is needed. In our Power-2-Integrate programme, we develop models for business cases. We also make a clear inventory of the most important issues. We put raw material and energy flows alongside market demand for chemical products and the opportunities of new technology.

Want to know more or participate?

Do you want to know what potentials there are for electrification of the production process? Do you want to use electrochemistry or plasma technology to convert a raw material into a specific product? And do you want it to be developed into a pilot and then implemented? We are happy to use our knowledge, experience and network to work together on a business case and accelerate implementation. This can be done in various ways:

VoltaChem community

The most accessible way is to join the VoltaChem community. This is a platform where companies exchange views on the progress of the programme, and where new alliances and projects are formed.

Research programme or project

We can set up a shared research programme, a bilateral project or a co-financing project. We are happy to discuss the possibilities and your requirements with you.

Get inspired

VoltaChem Year Event 2025

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale

Time setters: Smart windows bring climate-neutral living a step closer