Mass customization labs: innovation integration solar energy

Mass customization is a new PV manufacturing concept based on cleverly designed semi-finished products. TNO wants to use this concept to enable the production of a wide variety of affordable integrated solar energy end products. We are developing a research line, conceived by TNO and built by partners, that will demonstrate the industrial approach to create such semi-finished products as well as a facility to produce solar PV elements in many shapes, sizes and designs. As a next step they can be flexibly integrated into all kinds of surfaces and objects, such as facades and cars.

In our labs in Eindhoven and Petten we develop this new mass customization technology and together with companies, we design innovative solar energy products. Customization, low production cost and integration are the key concepts here. This responds to the demand from industry to incorporate solar PV functionality in their own products and thus no longer be dependent on the standard solar panels.

Shifting roles

These developments open the way for new entrants to the market or for existing parties to open up new routes. For example, a construction company will in the near future be able to order complete roofs in which solar cells and all electronics have been incorporated invisibly or in a pattern of their choice. We also anticipate changes in the supply chain: new players will be able to supply semi-finished products that manufacturers of building components and prefabricated products can then integrate into their manufacturing process.

Open innovation

Companies can make use of the open innovation environment of TNO in Eindhoven and Petten. The facilities are suitable for both silicon and thin-film PV technology and for the new high-efficiency solar cells, also knowns as tandems.

Prototyping, testing, analysing

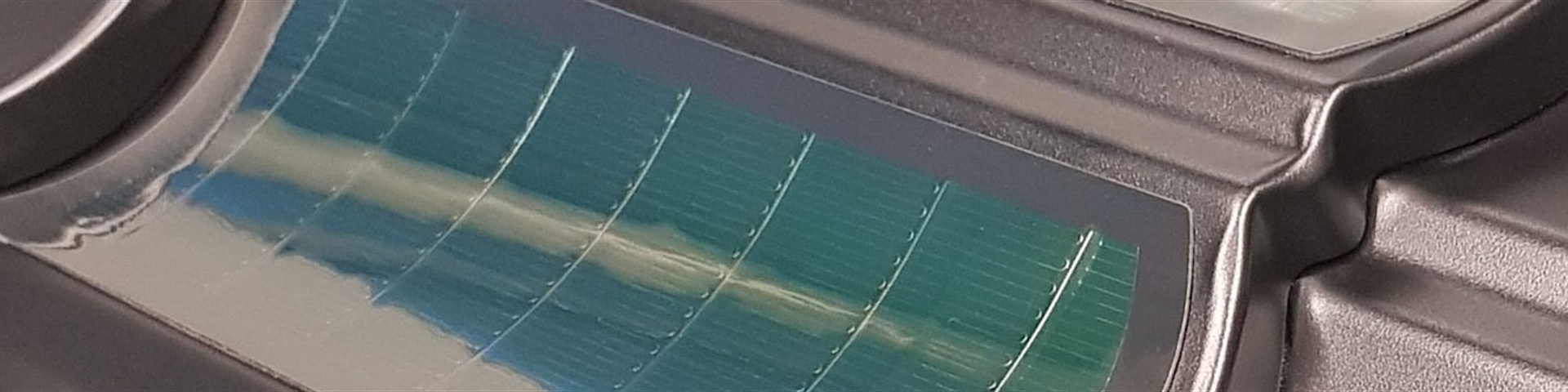

The research and development line that was commissioned in Eindhoven in 2022 is unique in the world: here we will make flexible laminates with solar PV functionality, in all conceivable variations of size, shape and electrical power. Vacuum lamination will soon be replaced by roll lamination, which will remove the restriction on the length of the material.

The new solar PV integration lab in Petten is especially equipped to conduct research on all types, shapes ands sizes of silicon based solar panels. This can be full solar panels or solar laminates that can be further integrated in various end products. This location also offers the opportunity to determine the energy yield of various products and examine lifetime, reliability and safety. The latter is important as mass customisation will lead to a wide variety of products with a higher complexity compared to the current generation of solar panels.

Get inspired

Shade screens with rollable solar foil combines energy generation with climate control in greenhouses

Dutch consortium develops manufacturing technology for perovskite solar cells

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

The next generation of solar technologies

Solar panel production back to Europe