Recyclable solar panels made in Europe

Status project

Duration until 2025

In cooperation with

PILATUS consortium

Traditional solar panels are constructed in such a way that you can hardly recycle them at the end of their service life. In a few years’ time, this should no longer be the case. There will then be an alternative design that makes individual components and materials more accessible and therefore easier to reuse. Factories in Europe and the US will be able to produce them, reducing dependence on Asia.

Recyclable solar panels 'Made in Europe'

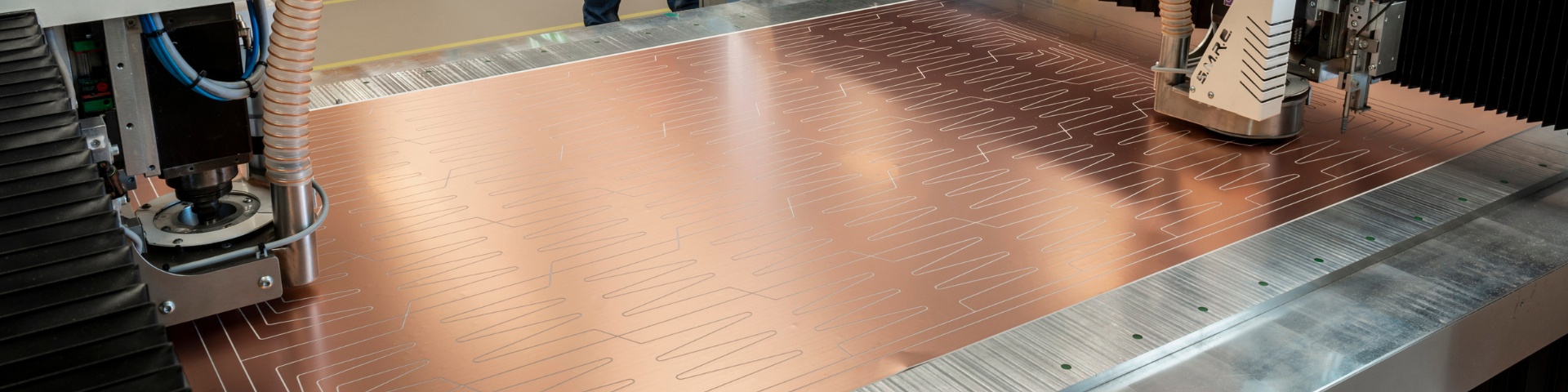

19 companies and research institutes are working together to achieve this in the EU Horizon project PILATUS. At the heart of this project is the construction of a pilot line to produce heterojunction silicon solar cells with back-contact technology (IBC SHJ) by 2025. TNO is contributing to this project with research and development of circular materials. The ultimate goal is a pilot line that will form the basis for manufacturing ‘made in Europe’ circular solar panels.

Easy to remove

TNO is involved in the project because it previously developed what is called the release encapsulant. The encapsulant normally forms a bonding layer to embed the solar cells in the solar module. It provides the necessary mechanical integrity, but is difficult to remove at the end of the product’s life. The newly developed encapsulant is easier to remove and ensures that the materials used in the panel can ultimately be easily separated again.

Webinar: The next generation of solar technologies

How to make solar energy smarter and greener? Join our webinar to delve into cutting-edge developments in photovoltaic (PV) technology, circular solar solutions, flexible modules, and tandem architecture.

“The long-term intention is to manufacture solar panels in Europe designed to be circular products. Good for the environment and for creating new business.’’

Circular solar panels: from waste to value

“The long-term intention is to manufacture solar panels in Europe designed to be circular products,’ says TNO expert Martin Späth. ‘Good for the environment and for creating new business. EU legislation is on its way: the Net Zero Industry Act and the Critical Raw Materials Act, aimed at producing circular products with reduced greenhouse gas emissions. In the PILATUS project, we’re working with companies that are already very active in this area. We need to move from weight towards value, that is to say, from tonnes of waste to recovering and reusing valuable materials, such as glass plates for solar panels, silicon and silver.’’

Recycling solar panels responsible decommissioning

Solar panels are still widely ground up in a shredder and end up as filler material in construction and road building. In the EU, this is the fate of some 4,000 tonnes of solar panels every year. In the Netherlands, an estimated quarter of a million panels will be due for removal by 2030. By 2050, this would involve 10 billion solar panels worldwide, weighing 60 million tonnes.

The motto is therefore ‘from shredding to responsible decommissioning’. In the previously completed, nationally funded DEREC project, TNO demonstrated in the lab that this is possible. In PILATUS, this will be applied to Meyer Burger’s heterojunction silicon (IBC SHJ) solar panels.

New factory

Swiss company Meyer Burger, which supplies machinery to produce solar cells and is coordinator of the project, will build a plant based on the new IBC SHJ technology. Another partner in the consortium, Norwegian Crystals (NCR), will supply the ‘wafers’ – the base material for making the solar cells. Here, the production process is being changed, so that the ‘waste’ created when the wafers are sawn to shape is completely reusable and new heterojunction solar cells can be made with the material.

Europe at the forefront

“The combination of knowledge and practice in the collaboration between the parties in this project will put Europe at the forefront globally. In Asia, huge investments have been made in precisely those technologies that we want to abandon here, because the resulting solar panels are not easy to recycle.

TNO is focusing in particular on circularity through a specific emphasis on the application of closed loop materials and disassembling a solar panel into pure components for further targeted recycling. Among other things, we test the manufactured solar panels in our climate chambers, with the aim of a practically feasible and cost-effective decommissioning process.’’

Much longer service life of solar panels

Apart from the fact that the panels will soon be circular, they’ll also last much longer. The aim is to extend the service life of solar panels from 25 to 40 years. The PILATUS project will be completed in 2025.

Read more about the PILATUS project

Study for Stichting Open

Upon request by Stichting OPEN we carried out a study giving an outlook towards future processes which may be used to extract all other valuable materials from discarded solar panels in addition to aluminum.

Get inspired

Shade screens with rollable solar foil combines energy generation with climate control in greenhouses

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

Carbon footprint floating solar energy systems similar to land systems

The next generation of solar technologies

Solar panel production back to Europe