Sustainable industry

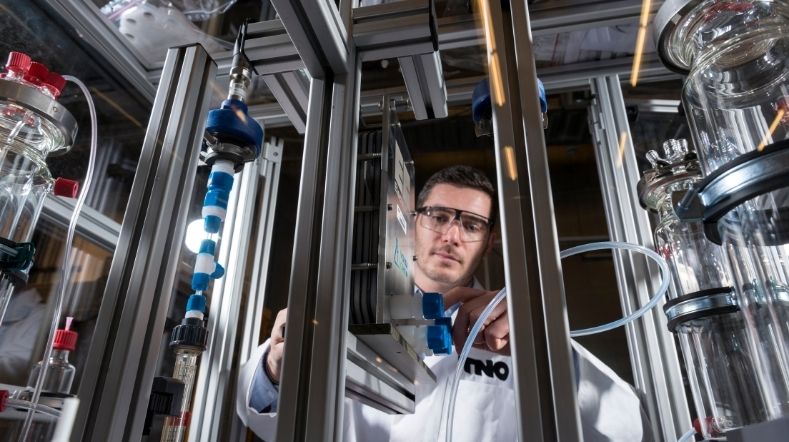

The chemical and process industries face enormous challenges. The pressure to reduce CO2 emissions, embrace circular economy and stay competitive at the same time is increasing. Companies are looking for ways to make their processes more sustainable without sacrificing efficiency and profitability.

At TNO, we understand these challenges. We research, develop and orchestrate breakthrough innovations that enable the transition to a carbon-neutral industry and society.

Towards a CO2-neutral industry

Industry accounts for about one-third of CO2 emissions in the Netherlands. We’re working to make industry carbon-neutral by 2050, so there’s a huge amount to do.

Our latest developments

62 resultaten, getoond 1 t/m 5

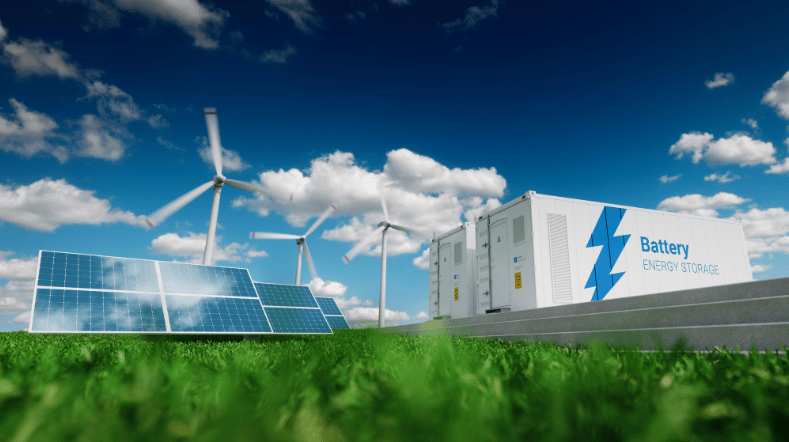

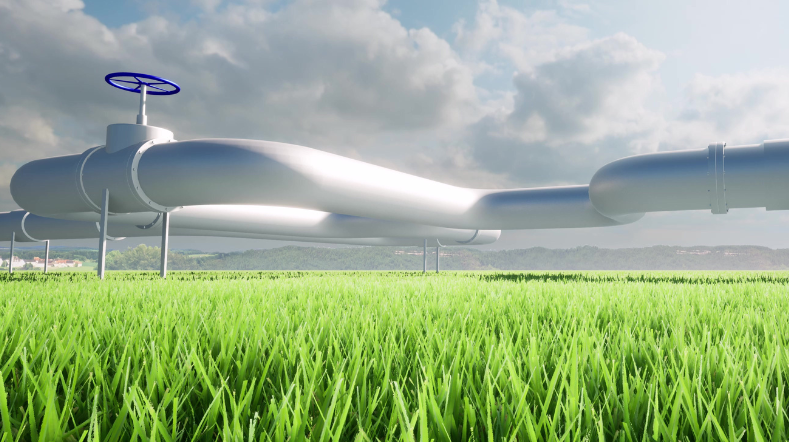

Energy infrastructure and transport

Together with our partners, we are developing infrastructure that safely, efficiently, and sustainably transports CO₂ and hydrogen across land and sea.

The North Sea as Europe's energy heart requires smart choices

Tomorrow’s hydrogen production and infrastructure: building towards a secure and robust energy system

World Hydrogen Summit 2025

Scaling-up electrochemical technologies for renewable ethylene production