Renewable syngas: essential for industrial decarbonisation

We are another step closer to renewable energy sources with the 'clean' production of syngas, thanks to the EU Horizon 2020 project SPOTLIGHT. The SPOTLIGHT consortium uses sunlight and photonics to convert CO2 and green hydrogen into green syngas. This even makes green syngas cost effective at a carbon tax of 200 euros per tonne. The project, for which TNO is the coordinator, was completed in June this year and is entering the next phase. TNO project manager Nicole Meulendijks, who was involved in this project, explains how this promising technology works and how it can make a difference.

How SPOTLIGHT is working on green chemicals

The SPOTLIGHT consortium was formed with a clear goal: to harness the sun as an energy source for sustainable chemical processes. Nicole Meulendijks (TNO) explains: "The sun helps convert raw materials such as CO2 and green hydrogen into green chemicals. These chemical building blocks can completely replace fossil building blocks, drastically reducing greenhouse gas emissions."

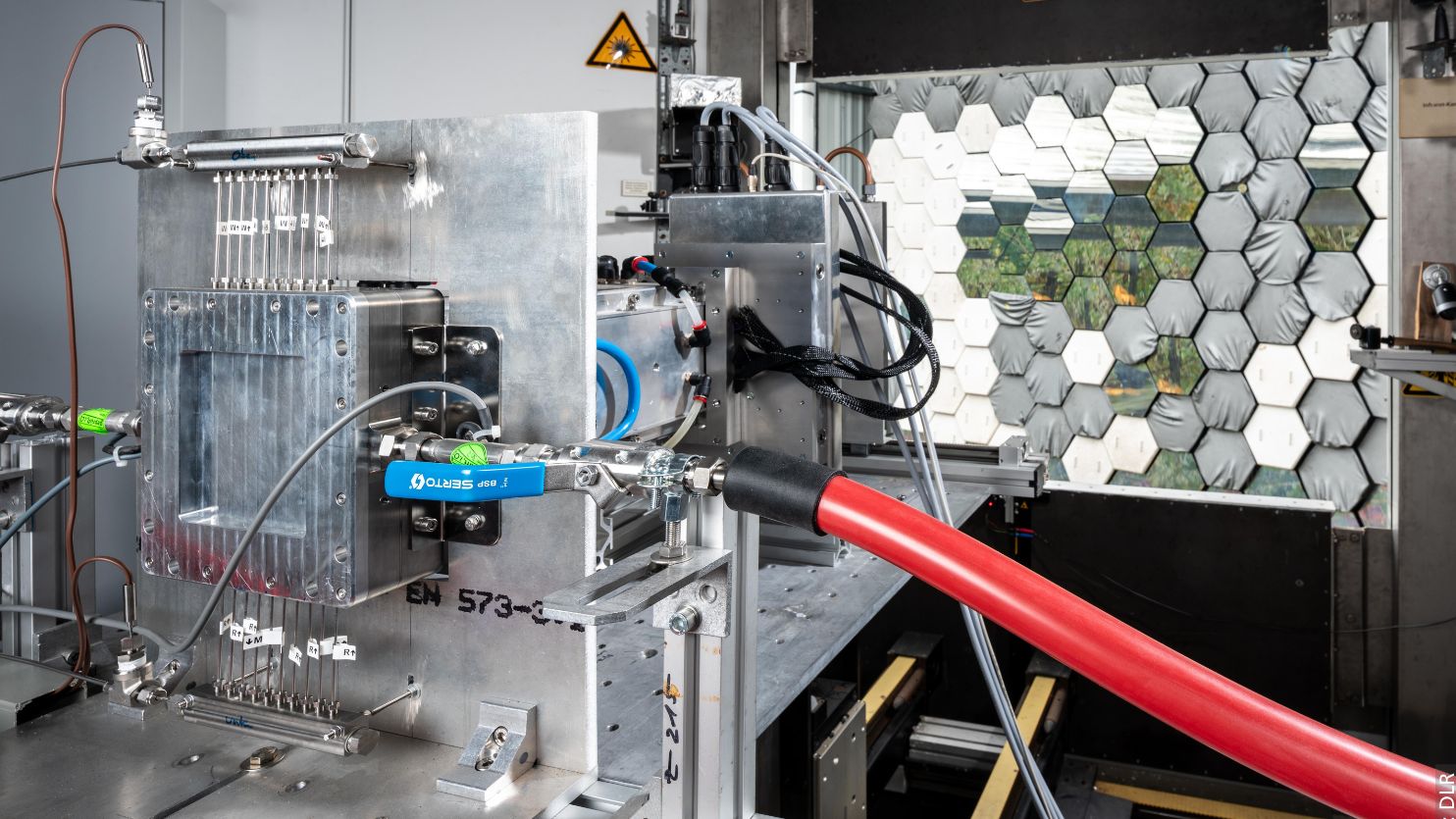

"At TNO, we manage the day-to-day activities of the consortium and contribute our expertise to the prototype", Meulendijks explains. "We supplied the catalyst, coordinated the construction of the equipment, and analysed the results together with partner DLR (the German Aerospace Centre). After initial testing in our facilities, the process was validated at DLR under real-life conditions."

Production of renewable syngas

The main objective of the project is to develop and validate a photonic device and chemical process to convert CO2 and green hydrogen into syngas (CO).

The production of green syngas serves as a basis for the production of hydrocarbons and methanol, for example. The technology can also be expanded for other applications, such as for the production of fine chemicals

By producing renewable syngas in this way, we are taking a promising step towards sustainable chemistry and reduced emissions.

Syngas is a mixture of carbon monoxide (CO) and hydrogen (H₂). It is used as a base for the production of valuable chemicals such as methanol.

By making syngas renewable, we can replace fossil fuels and reduce greenhouse gas emissions, contributing to a more sustainable chemical industry.

Sunlight and LEDs for clean energy

How does the technology work? "The technology to be deployed uses plasmonic catalysts", Nicole explains. "These materials absorb a lot of sunlight and are used in chemical processes driven by sunlight. By then tuning the catalysts, the reaction can be optimised for specific processes, such as syngas production."

The device developed for this purpose consists of 3 parts:

- a transparent plate-type reactor;

- secondary solar optics (mirrors and lenses): to focus concentrated sunlight on the reactor;

- an energy-efficient LED light source: for operation in the absence of sunlight.

This arrangement allows continuous operation even without sufficient sunlight.

Large-scale application is simple

The technology also supports carbon capture and utilisation (CCU), use of climate-neutral energy sources such as electricity and hydrogen, and sunlight as a CO2-free energy source for chemical processes. The modular design makes scaling up easy by simply adding more devices.

Watch the VR tour

Curious to see what the setup looks like in practice? We have prepared a VR tour that will take you through the high-flux solar furnace of our partner DLR (the German Aerospace Centre)

Technology development and scale-up

The production and validation of the photonic device for syngas production, among other things, has been successfully completed. Moreover, techno-economic analyses and life-cycle assessments have been carried out to assess its economic and environmental feasibility as well.

These analyses show that renewable syngas can become cost competitive. However, this is under the condition that the price of natural gas is at least around €3/GJ and that the CO2 tax rises from €90/tCO2 to €200/tCO2.

The technology will be further developed and scaled up to pilot scale in follow-up projects.

Want to know more about using sunlight as a renewable energy source to power chemical processes?

Get inspired

Power-to-X: cornerstone for decarbonisation and economic resilience of the chemical industry

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale

TU Delft and TNO prepare industry for scale-up phase of clean factory

Collaboration for European platform on industrial transformation