Surprisingly, in addition to packaging, car tyres and agricultural plastic biggest sources of microplastics in the Netherlands

A model developed by TNO shows that car tyres and agricultural plastic in particular, but also clothing, are a much larger source of microplastics than expected based on the absolute amounts of plastics used in the Netherlands. The use of packaging plastic is by far the largest source of plastic in kilograms and also a hefty source of microplastics. So, microplastics are not only a problem in water, but they also mainly end up on and in land. These insights provide tools to address the formation of microplastics, with an achievable reduction of 70%.

Read the white paper microplastics

Microplastics are everywhere: 70% reduction achievable.

Precautionary principle

The effect of microplastics on human health is currently insufficiently clear. The WHO recently reaffirmed this. However, we know enough about the health effects of other small particles such as (ultrafine) particulate matter to minimise the formation of microplastics based on the precautionary principle.

Life cycle of plastics in new model

Reducing microplastics requires a systemic understanding of the entire life cycle of plastics: their production, use, and end-of-life phase. This insight was lacking until now.

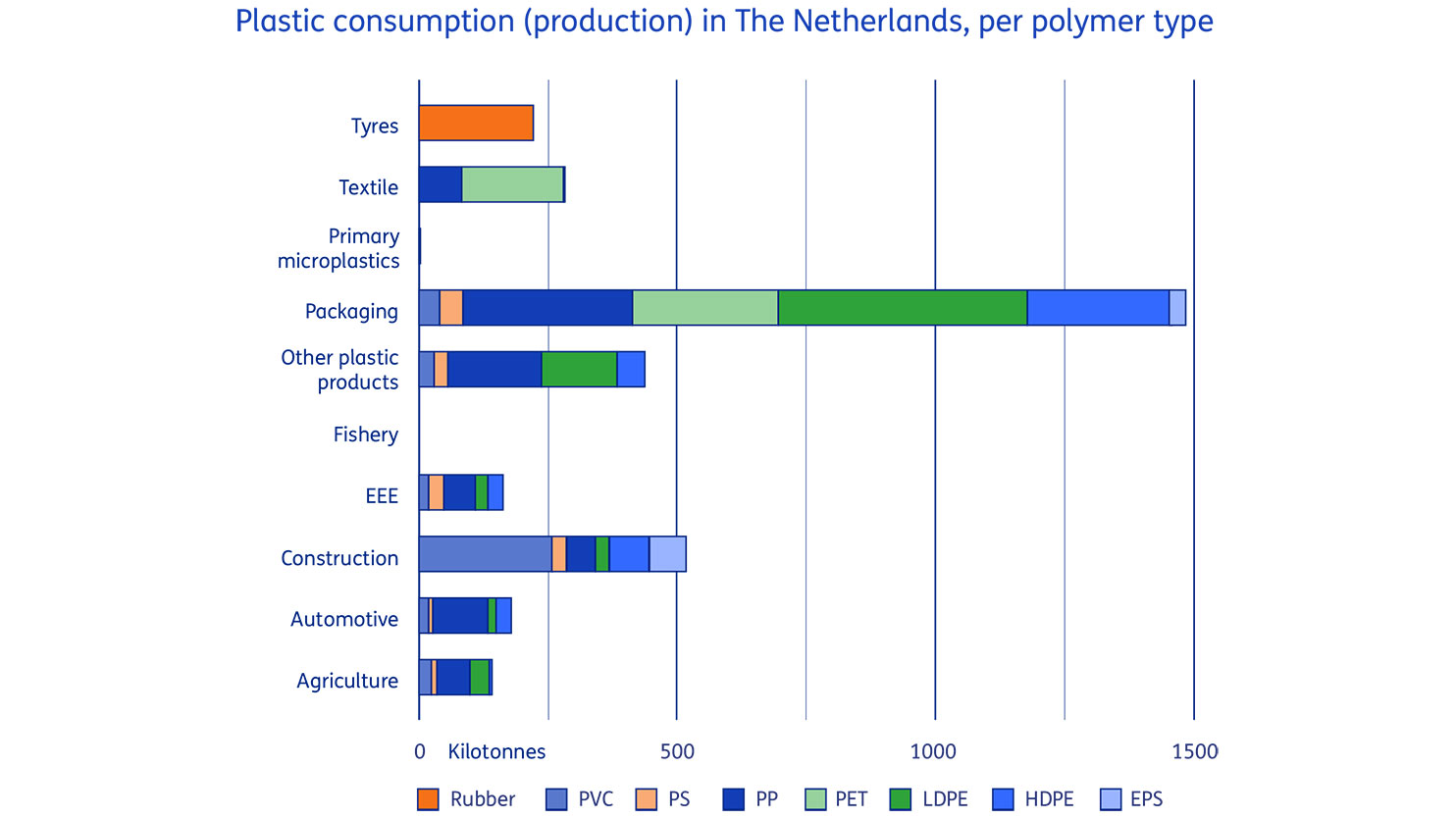

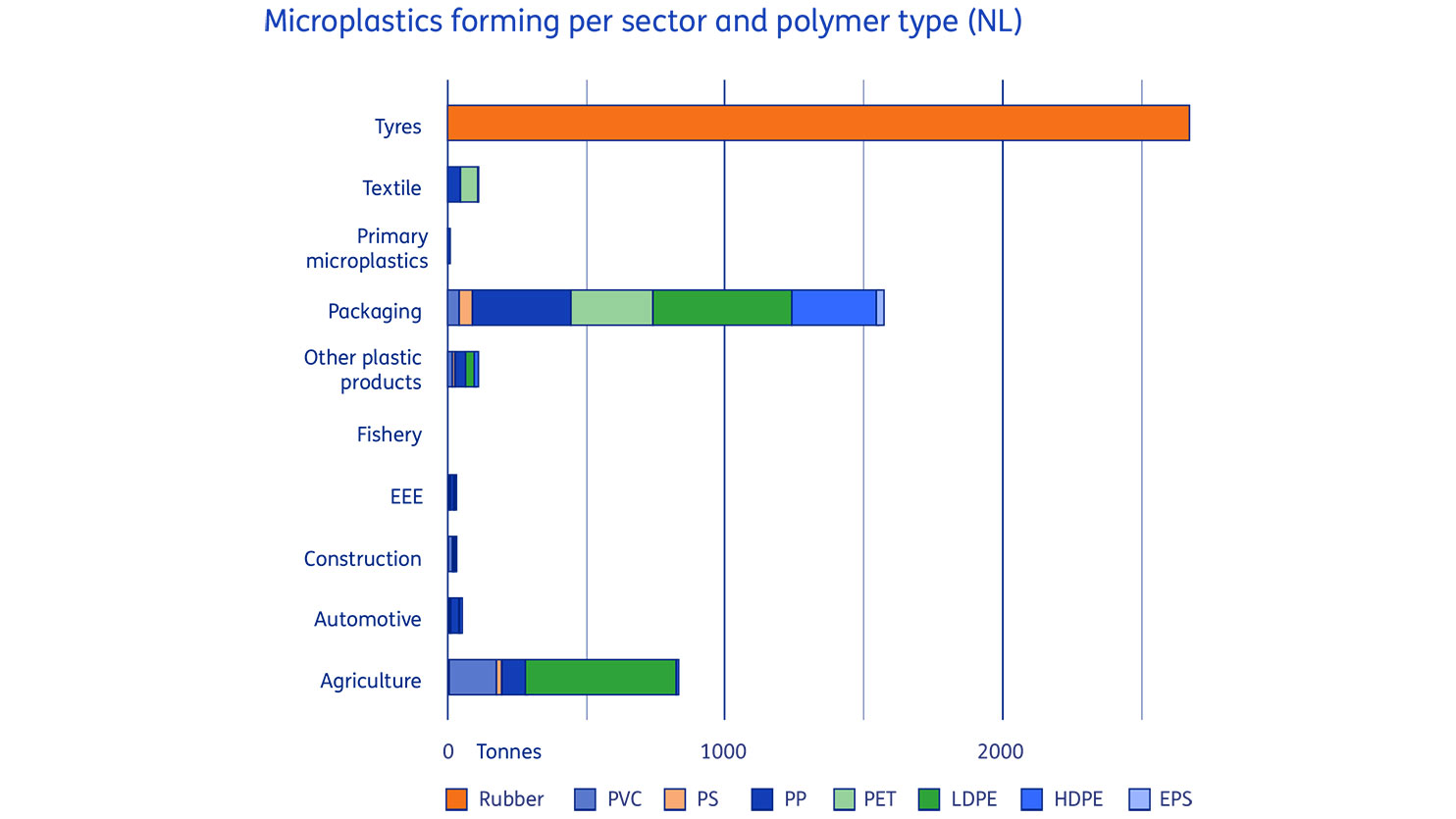

That is why TNO – based on validated databases and scientific publications – has designed a model that calculates which sectors make the greatest contribution to the formation of microplastics and where they subsequently end up.

TNO's Material Flow Analysis Model shows that car tyres, packaging, and agricultural plastic provide the greatest contribution in the Netherlands.

Mitigating microplastics: up to 70% reduction possible

TNO used the model to calculate the effectiveness of 17 strategies to prevent or reduce the formation of microplastics.

A variety of strategies that can contribute to the solution were considered in the following categories: policy, choice of materials, product design, recycling and separation technology, behaviour, waste management, and clean-up actions.

TNO researchers believe that implementing these strategies will allow a 70% reduction in microplastics by 2050 (37% by 2030), even in a scenario where plastics consumption increases.

Cost-effective measures

The Netherlands has much to gain from the roll-out of the 'R strategies' – Refuse, Rethink, Reduce – and associated technological, marketing, and behavioural concepts.

A major contribution can also be made by banning Single-Use Plastics (SUPs) and extending the system of disposal fees and deposits on returnable plastic items so as to positively influence ‘throw-it-away’ behaviour on the part of consumers. The same is true of the use of innovative materials that reduce the formation of microplastics resulting from car tyres and packaging.

Get inspired

Early results show the potential of circular healthcare plastics

Biobased materials

Enhanced solvolysis contributes to the future of composite recycling

Collaboration for sustainability: better results through joint innovation