Circular scenario models for insight into the circular value chain of materials

The Netherlands, like the rest of Europe, aims to achieve a 100% circular economy by 2050. This is a significant challenge, as the entire system must be adapted alongside the energy transition. To understand what is required for this circular transition, TNO is developing circular models. These models provide governments and businesses with independent insights into circular strategies and the system impact of the value chain.

Future scenarios for technology and policy

Through these models, we map out future scenarios for technology and policy. Our focus is on the broad value chain of materials, as well as specific materials such as the plastics value chain.

By gathering and processing large volumes of data, knowledge, and expertise – exclusively available within TNO – we can analyse system scenarios. This enables governments and large industries to make informed decisions about the transition to a circular economy.

We have developed two circular models for this purpose:

CITS Model: insight into the circular value chain of materials

One example of such a model is the ‘Circular Industrial Transformation System’ (CITS). The CITS model provides a clear overview and insight into how materials and products move through the production chain. Additionally, CITS calculates the impact of all these steps in the production chain, based on the Life Cycle Analysis (LCA) method.

It generates technology and policy scenarios using data related to the circular economy, analyses, and forecasts. This helps governments and businesses understand the long-term impact of their decisions and make sustainable choices.

CITS supports the development of strategies that balance economic and environmental objectives. The model also enables the analysis of the effects of various energy and recycling options and identifies synergies between climate goals and the circular economy.

In 2023 and 2024, TNO conducted a product group analysis for the PBL Netherlands Environmental Assessment Agency for the packaging product group. The goal of this analysis was to develop a circular future scenario .

Our results indicate that the demand for consumer packaging could increase by 17% between 2022 and 2050 if consumption patterns do not change. Currently, 55% of packaging material is not processed, and only a small proportion is reused as packaging.

An optimal circular scenario could reduce greenhouse gas emissions from packaging by 62% and decrease material use by 67%. Significant results in this scenario are achieved by avoiding packaging (refuse) and reducing the material used in packaging (reduce).

Additionally, new recycling technologies are crucial in these scenarios. A major challenge of a circular packaging scenario, is the high safety requirements for packaging. Chemical recycling may play a role here, as it can remove contaminants. However, many chemical recycling technologies come with a higher CO2 impact.

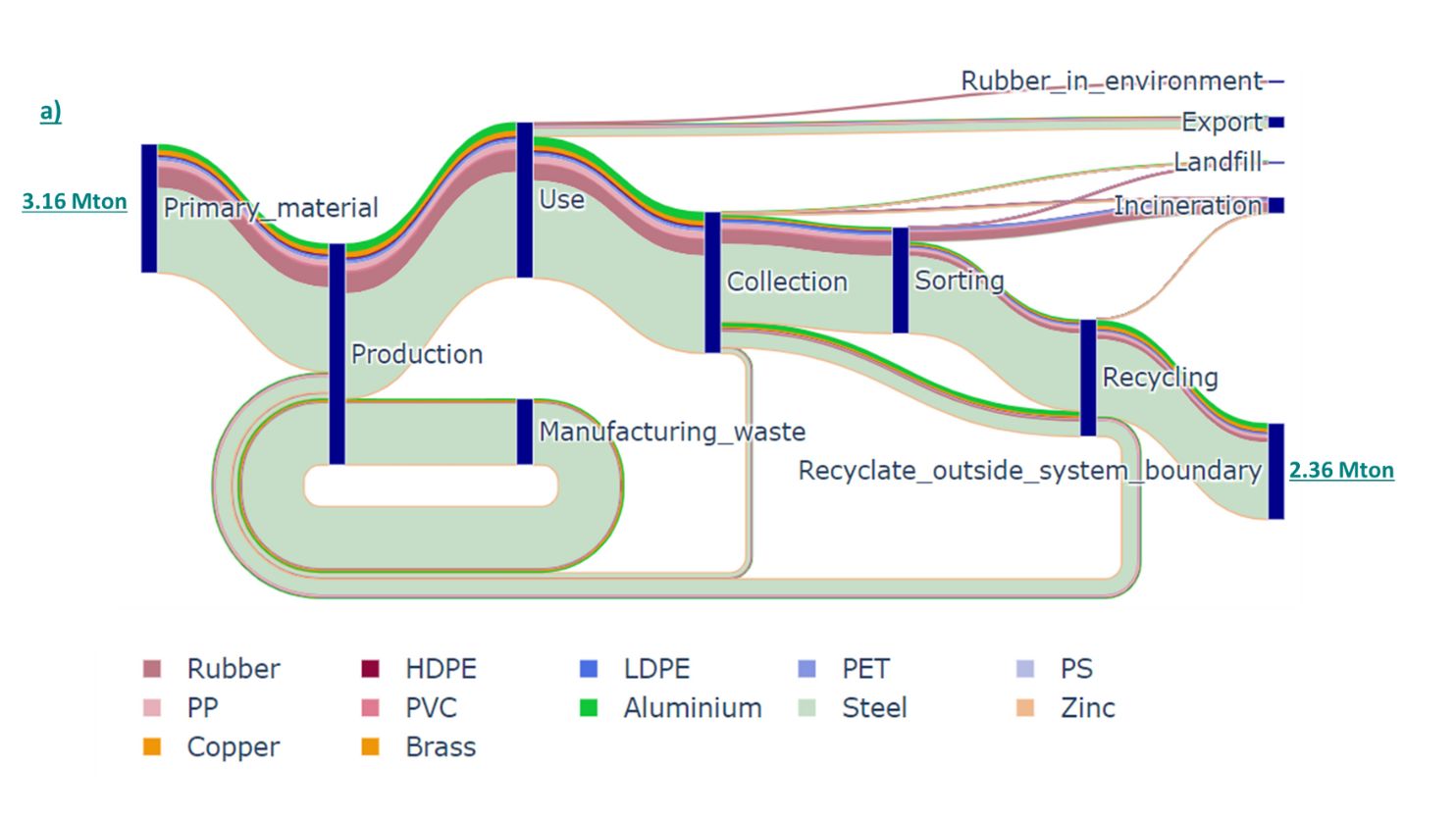

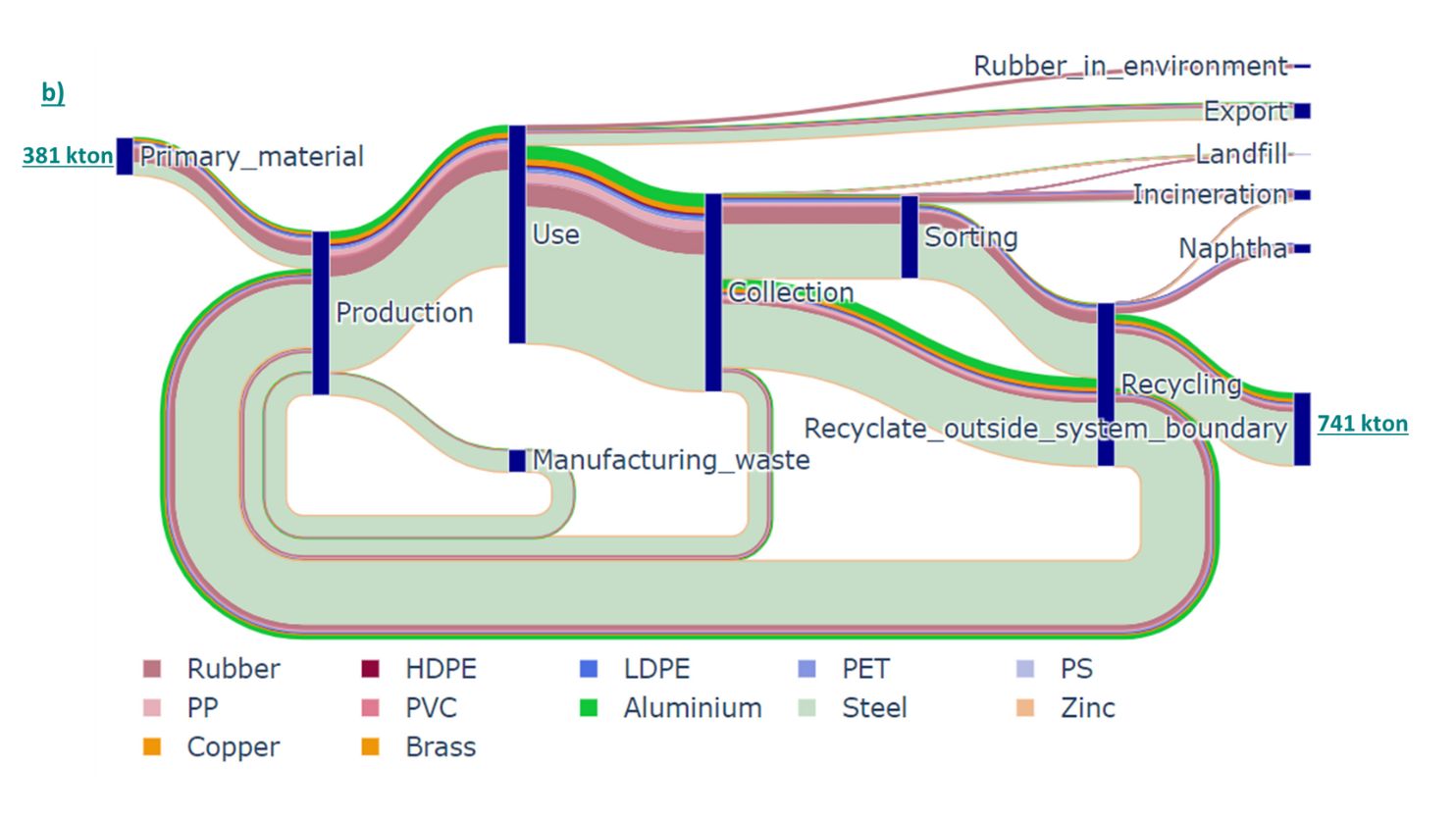

One of the results from the CITS model for the automotive sector is insight into the volumes of materials in the value chain. As depicted in the flowcharts below, the automotive sector as it is right now (A) requires a high volume of virgin materials; 3.16 Mton on a yearly basis.

However, in a future scenario with circular interventions (B), such as an increase in recycling, car sharing and lifetime extension of cars, virgin material demand decreases strongly, especially for metals, to about 381 kton per year.

With these insights, interventions and their effectiveness are highlighted, as well as their consequences in the value chain, such as an increase in recycling capacity.

Read the scientific article: The Circular Industrial Transformation System (CITS) model - Assessing the life cycle impacts of climate and circularity strategies.

TNO's PRISM model for deep dive into plastic recycling impact

In addition to the CITS model, TNO has developed a specialised model that focuses on plastics recycling, known as the Plastic Recycling Impact Scenario Model (PRISM). This model incorporates knowledge of all currently known recycling technologies, including innovative methods such as thermochemical recycling or dissolution. PRISM assists organisations in developing strategies for efficient and circular plastic design and recycling. We achieve this by modelling and optimising current and future plastic recycling routes.

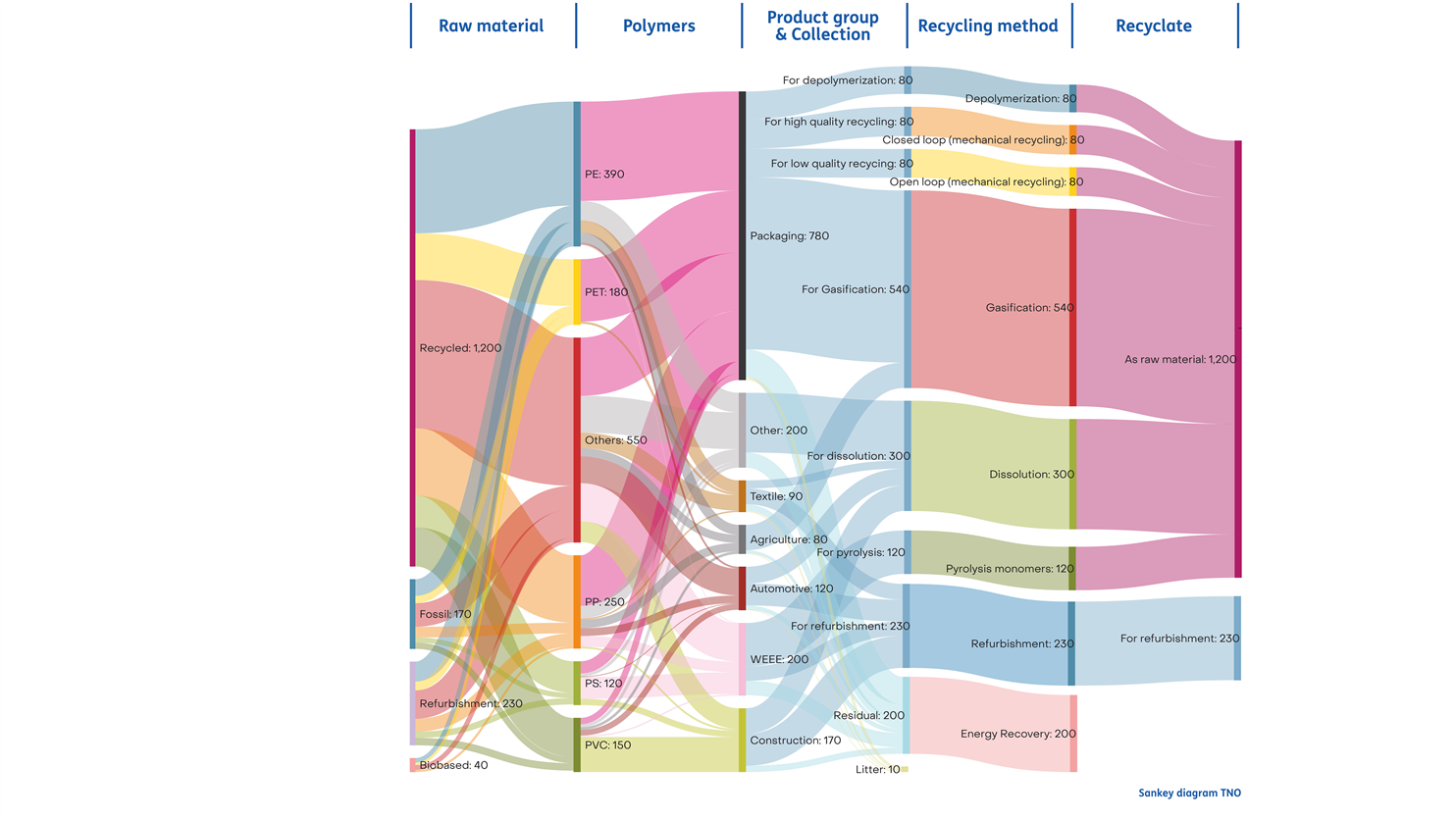

The figure shows a flow chart (a Sankey diagram) that represents how plastics can "flow" through our society in a circular economy in 2050, from raw material to end of life. Each color of the flow reflects a different process, and the thickness of the flow equals the size of the stream. The flow chart starts with raw material, which is either fossil (such as oil), recyclate (already recycled plastic) or bio-based (from agricultural products). The next column presents the type of polymers made from this. The third column shows the different product groups made from these polymers, such as packaging or electronics. Column four shows the flow of different methods of plastic waste collection and what the optimal recycling option is in 2050. Column five then shows how much new raw material we can produce from plastics by applying recycling.

PRISM demonstrates that it is technologically feasible to achieve up to approximately 87% efficiency in recycling, assuming we can manage to prevent all losses. This will require significant technological advancements in sorting and recycling, as well as other factors such as consistent policies, consumer acceptance, and a sense of responsibility across the entire value chain.

Download the whitepaper 'Don't waste it!'

Don't waste it! Solving the dark side of today's plastics.

Understanding the methodology for environmental impact calculations

The PRISM and CITS models both use the extensive knowledge TNO has on doing environmental impact calculations. These are ways of identifying the environmental impact in the chain of a product or process.

They consist of three core elements:

- Good reliable independent data

- Knowledge and expertise of the value chain

- Integrated assessments at system level. This allows us to investigate and solve problems integrally by combining assessment tools such as: Life Cycle Assessment (LCA), Life Cycle Costing (LCC), Techno-Economic Assessment (TEB) and scenario modelling.

For new technologies, it is challenging but not impossible to perform such calculations because the data is not always available. Nevertheless, it is still important to do this as early as possible, as these assessments can help design the technology.

Assessing sustainability early with so called prospective LCA’s can save costs and time, which can be spent on developing and marketing technology.

Does your company produce or process plastics? Ensure you are well-prepared for the future with new business opportunities!

Get inspired

Plastic waste in Indonesia gets value in 2 new P4G projects

TNO developed Waste treatment Tool for plastics in rivers