Industrial transformation

The transformation to a carbon emissions-free and circular industry by 2050 is feasible and affordable if the right choices are made. However, the many possible choices threaten to slow down the decision-making process. We therefore approach the industrial transformation from a system perspective. Discover how we do this.

Dutch industry: a strong position, but the future is not guaranteed

The Dutch industry is productive and internationally competitive, but faces pressure from globalization, geopolitical tensions, and rising energy costs.

According to the TNO report 'Dutch Industry: Strong Position, but No Guarantee for the Future', coherent industrial policy, European collaboration, and targeted investments in innovation, CO₂ infrastructure, and hydrogen are essential to preserve value chains and ensure a robust, future-ready industry.

We support major consumers such as the steel industry, petrochemicals, and refineries in their strategic decision-making by calculating the consequences of choices. In addition, public authorities can make informed decisions to accelerate the industrial energy transition. And to keep the energy and raw material supply clean, available, and affordable for the future.

Reports

This overview contains various reports on industrial transformation.

If we really want to get the Clean Industrial Deal off the ground, we have to dare to make choices. TNO's fact sheet brings the core into sharp focus: reduce electricity costs for industry, invest in strategic infrastructure, and opt for technologies with proven impact.

TNO's independent analyses help governments and companies choose a direction. Because without clear priorities, the transition will remain stuck in good intentions.

Download the fact sheet (pdf) (in Dutch).

Energy-intensive industries in Northwest Europe face mounting pressure from high energy costs and transition demands. The new WEC NL study Valuing Industries outlines four scenarios for 2040, from full retention to full relocation. It calls for a social cost-benefit analysis and highlights risks related to CO₂ emissions, energy infrastructure, and strategic autonomy.

Download the report 'Valuing Industries' (pdf).

Accelerating the industrial energy transition

The goals of the Dutch national government and the European Union are clear: a 55% reduction in carbon emissions (compared with the 1990 benchmark year) by 2030 and zero carbon emissions by 2050. That means a very steep drop in emissions over the next 8 years, while negative emissions will actually be required over the following 20 years. In addition, there are targets in the area of circularity. Although this transition affects all sectors, industry, as the largest emitter (32%), faces the biggest challenge.

Emission-reducing potential

Fortunately, large industrial consumers have many emission-reducing options to choose from for their industrial transformation, such as energy capture, storage, and conversion. There’s still considerable energy-saving potential in existing processes. But companies can also invest in completely new and more efficient processes.

Green energy carriers

Industry can also reduce its emissions by replacing fossil raw materials with organic alternatives. Another important step towards decarbonisation is the use of sustainable energy carriers, such as green electricity, green hydrogen, and ammonia.

Blue hydrogen

Where renewable sources are not sufficient, it’s also possible to make cleaner use of fossil fuels. By converting the carbon dioxide in natural gas in advance (blue hydrogen) or capturing it after combustion and storing it underground, you avoid the large emissions into the atmosphere. If this CO2 is extracted from biogenic raw materials and stored underground, you can even achieve negative emissions.

Circular raw materials

Industry is also at the beginning of the transition to circular raw materials such as waste (recyclate), bio-based raw materials, or CO2. With the help of renewable electricity, it’s even possible to use carbon dioxide as a raw material for high-quality chemical products, for reinforcing concrete, or as a transport fuel, for example.

Links of industry chain interdependent

The biggest challenge for industry is that the consequences of its choices are extremely difficult to identify. Many branches of industry are already interlinked with suppliers and customers, and these chains will also change due to the energy transition. The consequence of this interdependence is that every decision not only affects a company’s own operations, but also the chain and, ultimately, the entire energy and raw materials system. Collaboration is therefore essential for industry to be sustainable, reliable, and affordable.

Importance to society

In order to keep the various transition paths heading in the right direction and to orchestrate the industrial transition, we need an independent organisation that can connect all the links. As a non-profit organisation, we’re the right party to represent the interests of society in the energy transition. Our independent scientists provide not only the technical competence to shape the industrial transformation, but also insight into legislation and regulations, open innovation, and transition modelling.

Mission-driven research on industrial transformation

Companies want to know the best time for them to invest in sustainable technology. Public authorities have the societal task of keeping industrial production clean, reliable, and affordable. For their part, citizens are concerned about the consequences of climate change, high energy prices, and liveability.

Fortunately, the models show that the cost price of steel, plastics, or, for example, fertilisers does not increase significantly in emission-free production. But the companies and public authorities do have to make the right choices, work together, share burdens, and make appropriate plans for the transition. This is where TNO, with our mission-driven research, can be a strong, independent partner.

Get inspired

Producing renewable DME using renewable energy and CO2

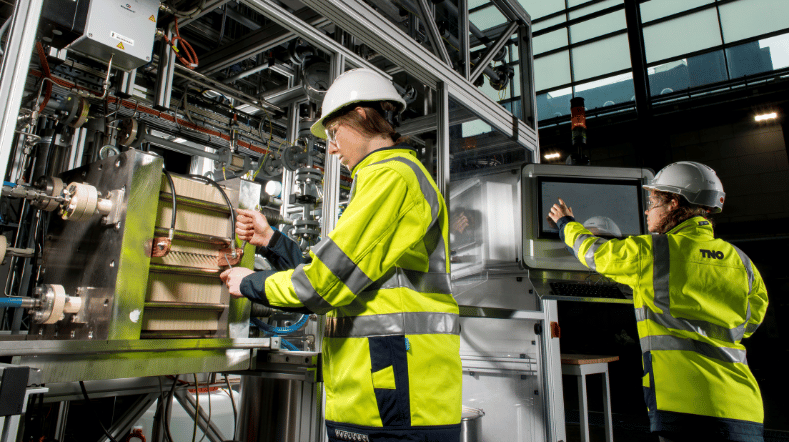

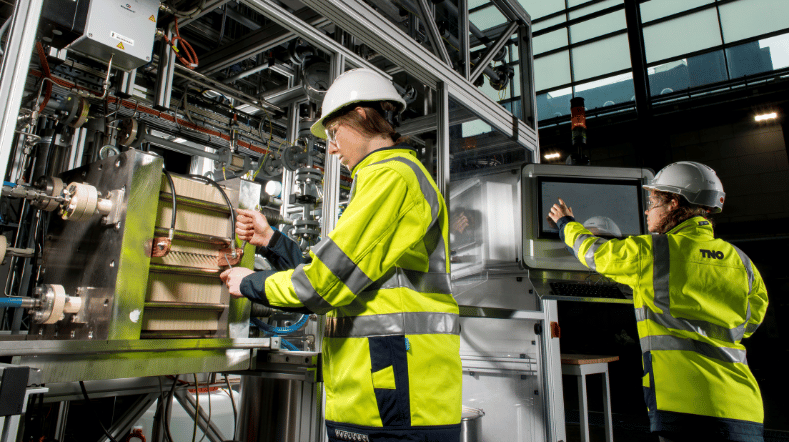

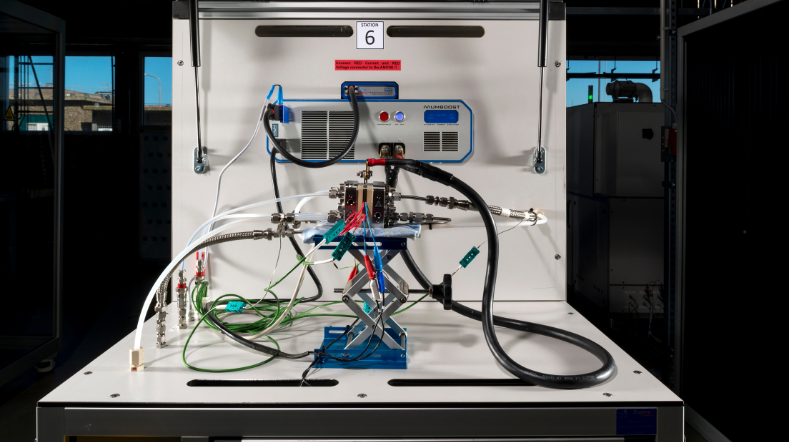

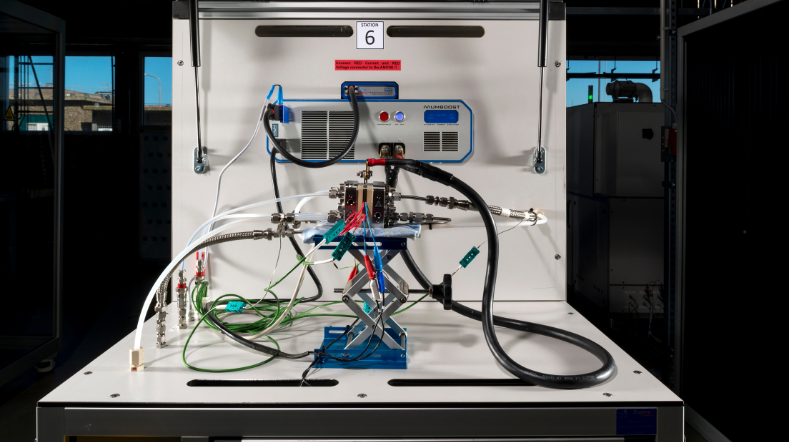

Unique test installation for CO2 capture and conversion to green chemicals

Climate goals achievable with strategic approach

Breakthrough electrolyser development: 200 times less iridium needed

TNO and partners to work together to boost the efficiency of renewable hydrogen production