Solar panel yield rises

Solar panels have been achieving good yields for years. They’re affordable and reliable, but there are still further gains to be made. For example, we expect a doubling of the conversion efficiency of photovoltaic (PV) systems. And it will be possible to reduce prices by at least a factor of 3. We’re working on technology to enhance performance and reduce costs.

Various types and sizes

Solar panels come in a number of types and sizes. There are the well-known solar panels, but also bifacial panels and panels with cells where all the contacts are on the back. Independently of the form, there are 3 categories of PV technology:

- based on crystalline silicon slices

- based on thin-film solar cells

- based on stacking individual solar cells, for example, a tandem.

Crystalline silicon PV

The most widely used technology for solar panels is crystalline silicon. It has been around for more than 50 years and has a global market share of 95%. More than half of all solar panels worldwide contain TNO technology. The yield of silicon solar cells manufactured on a large scale has risen sharply in the last decade, to more than 20%. Silicon is derived from the Latin word silex, meaning flint. It used to be called ‘silicium’, with the ‘-ium’ ending because it resembles a metal.

The latest technology worldwide

The expected maximum efficiency of solar panels is estimated at 26%. Together with our partners, we want to get closer to that level, through new developments and applications. A specific example is to apply functional layers to the silicon to make complete solar cells. These are ultrathin layers, down to several thousandths of a micrometre thin – i.e., nanometre thickness. We’re developing this technology in our solar lab, together with companies and other knowledge institutions, and we’re global leaders in this field.

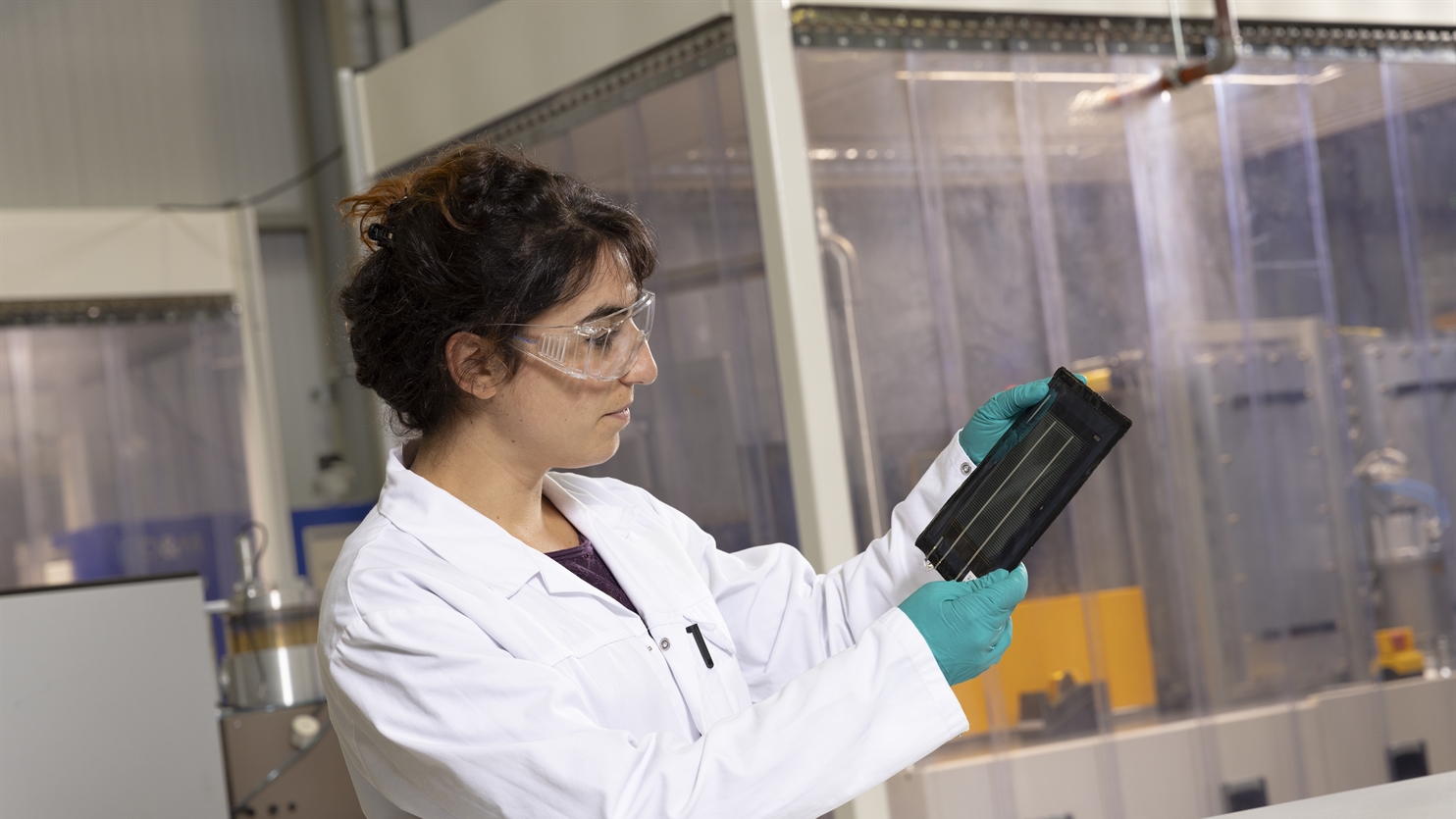

Thin-film solar cells

Thin-film photovoltaic (PV) cells and modules, which can be applied flexibly, are an alternative to silicon. Silicon solar cells are currently around 150 micrometres (0.15 millimetres) thin. In thin film, this is 1 to 3 micrometres. These are very different materials, which are applied so thinly that they make flexible PV modules possible.

Efficient solar panels in all types and sizes

We focus mainly on the 2 materials Copper Indium Gallium Selenide (CIGS) and the new perovskite. CIGS solar modules are already being produced on a large scale. Due to its flexibility, thin-film PV is easier and more widely applicable than silicon. The modules also look better because they are uniform in colour. The technology we’re working on integrates the thin-film solar cells into products with a wide variety of shapes and colours (customised products). And we’re focusing on packaging technologies that make the products highly reliable.

Collaborating on thin-film solar cells

In the thin-film PV lab, we’re working on thin-film PV technology together with industry, universities, and other research institutes. Much of the research is done within the Solliance partnership, in which we are a key partner.

Stacking solar cells in a tandem

Energy from sunlight is better exploited by using tandem constructions. These are combinations of silicon and thin-film solar cells or combinations of thin-film solar cells. Such combinations boost the solar cell yield, up to about 1.4 times higher than simple solar cells. The efficient solar panels require less PV surface area, which is essential for a densely populated country such as the Netherlands.

Greater efficiency of solar panels

The higher yield of tandem constructions reduces the system costs, such as cables and supporting constructions, in relative terms. The costs per kilowatt hour are also lower as a result. In addition to a better yield and lower costs, we’re also working on scaling up production processes and extending the service life of the tandem modules. We now test not only in the lab but also under real outdoor conditions.

Bifacial solar panels

Solar panels normally capture sunlight on one side only. We were among the first to develop bifacial solar panels, which are now used on a large scale. They provide 10 to 20% higher energy efficiency than monofacial panels, depending on environmental reflection. However, the manufacturing costs are comparable. Therefore, with the right application, bifacial solar panels provide a lower cost per kilowatt hour. For example, on large roofs, inland waterways, the sea or farmland where crops grow or cattle walk between the rows.

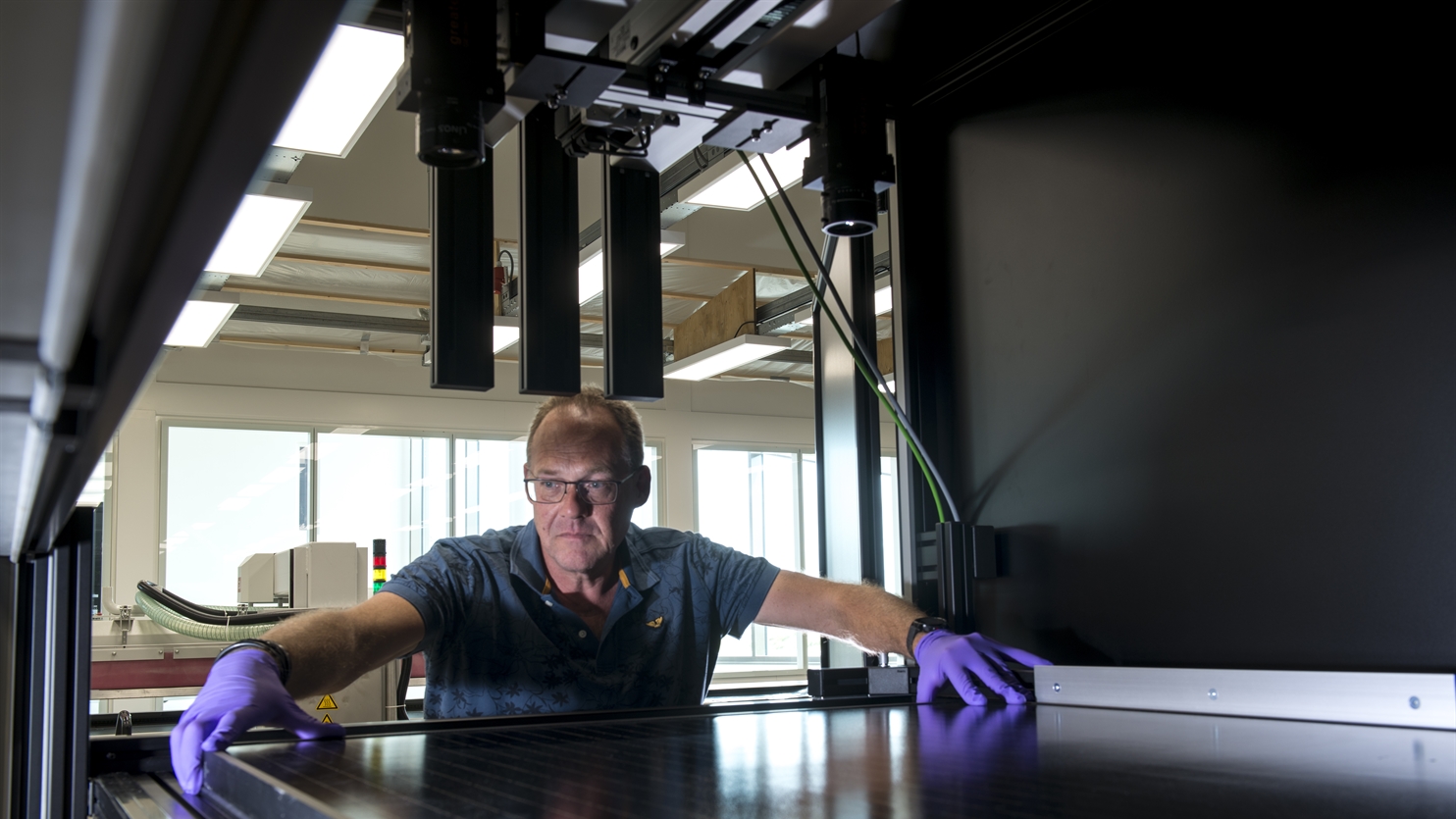

Technology for the back of the panels

Together with partners in science and industry, we’re also working on back contact silicon solar cells and modules. Here, the electrical connection of the cells is at the back. The metal covering at the front is therefore partially or completely absent, so that the metal patterns are barely visible, if at all. Also, there are no more shading losses and resistive losses are minimised.

Improving the technology

We’re optimising this technology with industrial partners, including manufacturers of materials, machines, cells, and modules. We’re also working on the resulting products, for example for integration into buildings and cars.

Trends in solar panels

You can find more about the market share, efficiency, and trends in solar panels in Issue 12 of the International Technology Roadmap for Photovoltaic (ITRPV), which was published at the end of April 2021. Solar Magazine published an article (in Dutch) with some of the key conclusions.

Webinar on innovations in solar energy technology

Solar energy has become affordable and reliable thanks to innovation, scaling up, and standardisation.

Get inspired

Shade screens with rollable solar foil combines energy generation with climate control in greenhouses

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

Carbon footprint floating solar energy systems similar to land systems

The next generation of solar technologies

Solar panel production back to Europe