Thin-film solar panels and circular design

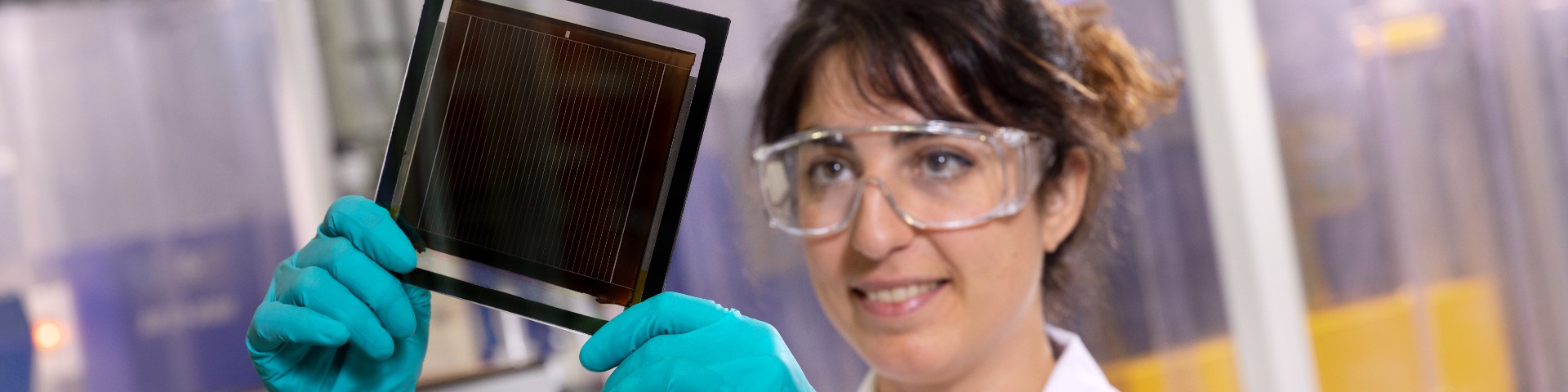

We develop advanced module technologies for packaging, interconnection, and sustainability of thin-film CIGS and Perovskite PV. This research is part of the Solliance Shared Research Program for Innovative Module Technology.

Customised interconnection

New integrated solar systems, used for example for vehicle integration, may vary in their dimensions. They may also be curved to fit the surface of the application into which the solar system has been integrated. This calls for new designs and flexibly adaptable manufacturing technology to adapt the solar panel’s electrical design to the product.

Currently, thin-film solar cells in a module usually consist of long, straight strips. But new shapes may require curved, rounded, or oddly shaped cell designs. To meet this requirement, we want to demonstrate a fully digital back-end interconnect process for CIGS and Perovskite-based solar cells in the coming years. This will make it possible to produce solar modules in any shape and output – flexible and robust modules based on CIGS or Perovskite technology.

Protecting longer service life

Another step towards low-cost integration of custom thin-film modules is the development of reliable and inexpensive protection and packaging. The service life of a solar panel is a critical factor in the cost of electricity production. Glass is the perfect packaging material for rigid applications. But because it’s rigid and fragile, it isn’t suitable for the flexible applications of thin-film PV.

Through our research on cost-effective packaging materials and application processes for lightweight and flexible applications, we’re creating technologies for the planned use of customised thin-film in vehicles, infrastructure, and buildings.

Circular design

The guiding principle for any new module technology and any design is to minimise material and energy consumption in production. And at the end of the service life, it should be possible to separate components and materials properly for reuse and reprocessing. The aim is also to conserve the energy used to clean, process, and shape the material. This means not grinding or pulverising products for reprocessing, but instead leaving components such as glass plates, silicon wafers, and fibres as intact as possible, and making them available for reuse.

Solliance

As TNO, we carry out research on thin-film solar technology in the Solliance partnership. This partnership was set up by the Dutch TNO, Belgian imec, and ECN (Energy Research Centre of the Netherlands, part of TNO since 2018). Together with industrial and academic partners, Solliance Solar Research is playing an ambitious role in worldwide research to create the solar technology of the future.

Get inspired

Shade screens with rollable solar foil combines energy generation with climate control in greenhouses

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

Carbon footprint floating solar energy systems similar to land systems

The next generation of solar technologies

Solar panel production back to Europe