Towards carbon-neutral industry

Industry accounts for about one-third of CO2 emissions in the Netherlands. We’re working to make industry carbon-neutral by 2050, so there’s a huge amount to do. The target for 2030 is to cut harmful emissions by half. We support government, industry, and the business community in this transition.

Towards carbon-neutral industry

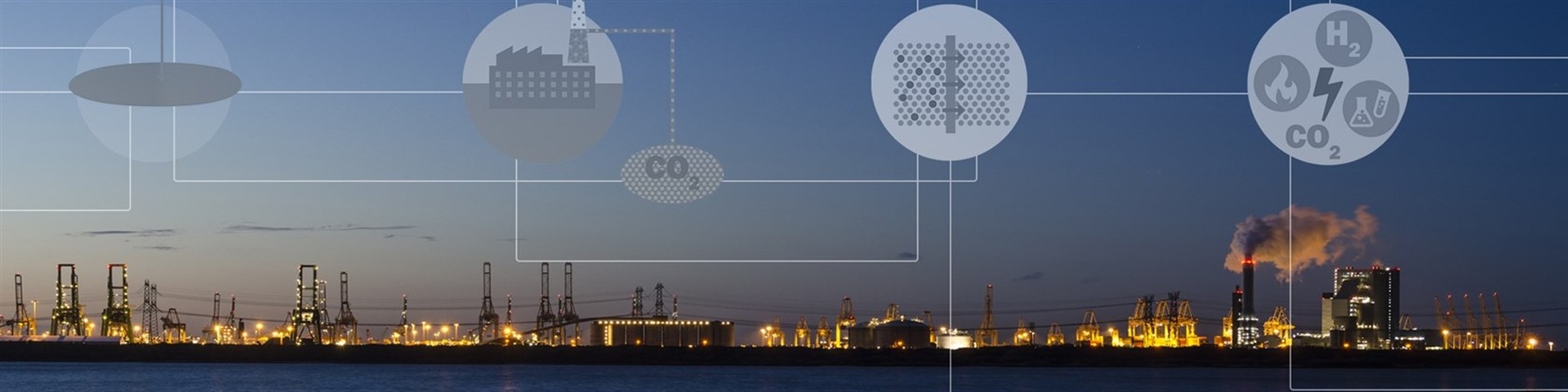

The Netherlands is almost entirely dependent on fossil fuels and raw materials. The following 4 solutions will ensure climate-neutral energy consumption, so that CO2 emissions will be eliminated by 2050:

- making heat management sustainable

- carbon capture, reuse, and storage

- electrification of production processes (sustainable electricity replaces fossil fuels)

- efficiency and circularity

TNO helps cut carbon emissions

We work together closely with the Dutch government and the business community. We’re developing innovative technology that can be brought to market in the near future, in order to accelerate hitting the targets for CO2. In doing so, we ensure that the energy transition:

is cost-effective creates new export and other opportunities for the manufacturing industry in the Netherlands makes the Netherlands an attractive location for new sustainable industry.

We also carry out feasibility and transition studies, and collaborate in large partnerships with companies and knowledge institutions. We describe below the solutions we’re working on for each area involved.

More than 80% of industrial energy consumption is related to the use of heat, from temperatures below 100oC to above 1,500oC. Heat currently comes mainly from fossil fuels that emit CO2, such as gas, oil, and coal. More research and development of industrial heat technologies is needed to achieve the climate targets.

We’re investigating how to supply high-temperature heat using carbon-neutral fuels. These include biomass, hydrogen, sustainable electricity, and metal fuels. We’re also working on heat pump and heat storage technology for a more efficient process of reusing and upgrading residual heat from industry.

At refineries, waste processing plants, and steel companies in the petrochemical industry, benefits can be achieved by capturing CO2 so that it isn’t emitted. One of the technologies we’ve developed for this purpose is the Sorption Enhanced Water-Gas Shift process (SEWGS) (see box). This is already being used in industry.

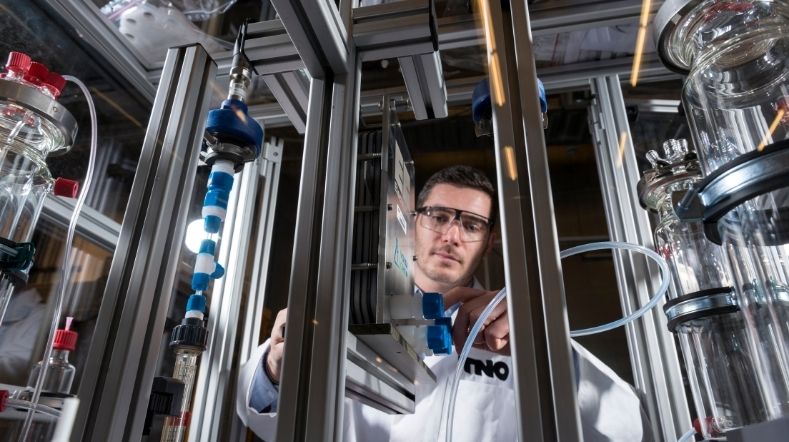

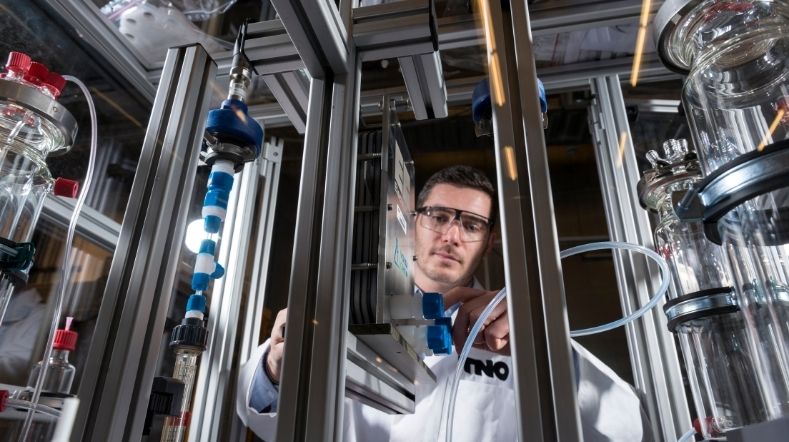

Fluids for carbon capture

Another promising technology is based on liquids. At waste processing plants, we use our unique mobile capture system to analyse flue gases that are released. These measurements can be used to design and build installations for large-scale carbon capture. This technology is currently at the final step before market introduction.

Extracting CO2 from the air

We’re also working on evaluating and developing technologies to extract CO2 directly from the air. This is called negative emission. This should lead to a reduction in the amount of CO2 in the atmosphere, from 400 CO2 parts per million to the pre-industrial level of 300 per million.

Reducing CO2 emissions with SEWGS

Using the SEWGS absorption technology, with solid sorbents, the steel industry can remove CO2 during the production process in a relatively low-cost manner. It’s no longer necessary to capture carbon from the chimney.

In addition, SEWGS is a revolutionary Dutch platform technology that’s attractive for producing blue hydrogen from industrial residual gases and synthesis gas. Industry can use the technology to produce hydrogen more cheaply, more energy-efficiently, and on a larger scale than is currently possible with green hydrogen.

Electrification of production processes

Converting wind energy to hydrogen

Offshore wind farms are an important source of renewable energy. But when electricity is generated offshore, it has to be integrated into the existing energy system on land. The energy also needs to be stored, because energy supply and demand are constantly changing. Converting electricity from offshore wind into hydrogen makes it possible to transport and store energy in the form of electricity and molecules.

Cheaper and very suitable for use

Converting the energy offshore makes transport to land cheaper than through an electricity cable. On land, the green hydrogen can be put to good use in industry, the built environment, or transport. It’s expected to become commercially viable to produce hydrogen offshore after 2030.

Clean hydrogen

We’re working on technology to produce carbon-free hydrogen, through electrolysis using electricity from wind and solar. But this technique is still too expensive and too small-scale. Together with innovative companies, we’re organising a network to take electrolysis to the industrial scale. We’re doing this together with various parties, including equipment builders and material suppliers, in the Faraday Lab, the largest and most advanced hydrogen research facility in Europe.

Making fuels carbon-neutral

Carbon-neutral fuels are needed to make heavy transport, shipping, and aviation more sustainable. We’re working on production technology for biofuels and synthetic fuels. Valuable chemicals and fuels can be made from waste streams, such as waste wood and agricultural residues.

The search for affordable solutions

In our biofuels lab, our experts are working with companies on affordable solutions to convert these biomass waste streams into environmentally friendly biofuels. We’re also focusing on developing technologies to produce synthetic fuels made from CO, CO2, and hydrogen.

Efficiency and circularity

Integrating new technology

New ways of generating energy must always be integrated into the existing energy system; this is called systems integration. The energy sources listed above require existing infrastructure to be adapted and, to some extent, new infrastructure to be built. Other sustainable gases, such as green gas, synthetic gases and CO2, as well as raw materials or semi-finished products, may also require new infrastructure.

Current projects

We’re involved in all major initiatives aimed at achieving carbon neutrality by 2050, in collaboration with public authorities and businesses. We focus on developing technologies and on economic feasibility, affordability, security of supply, and safety of the infrastructure.

Take a look at the projects we’re working on:

- The North Sea Energy Programme: research on systems integration in the North Sea.

- PosHYdon: a trial to produce green hydrogen on a North Sea platform

- HY3, with Germany: a project to bring green hydrogen from the North Sea to the industrial clusters in the Netherlands and abroad, such as Antwerp and the Ruhr area.

Changing industry

Another solution we’re working on is to redesign industry, which currently runs on fossil fuels and raw materials. These technological developments are for the long term, around 10 to 20 years. Together with experts from various disciplines, we’re devising new processes and materials, taking account of the consequences for society. We share these insights with the business community and government.

The impact of COVID-19

In 2020, the COVID-19 pandemic led to a reduction in global carbon emissions. We now travel, work, and communicate differently. The question is whether there is a lasting effect that reduces CO2 emissions and accelerates the energy transition. Partners in the World Energy Council in the Netherlands have jointly done research on this topic and summarised their findings in the report.

Get inspired

Energy infrastructure and transport

The North Sea as Europe's energy heart requires smart choices

Tomorrow’s hydrogen production and infrastructure: building towards a secure and robust energy system

World Hydrogen Summit 2025

Scaling-up electrochemical technologies for renewable ethylene production