TNO Green Print accelerates sustainable industry

Industry is responsible for almost half of the energy consumption, CO2 emissions and use of raw materials in the Netherlands. To accomplish a sustainable industry is a huge task which requires taking radical long- and short-term decisions on an ongoing basis. Making the right decisions not only requires facts and figures, but also insight into how the value chains of industrial companies, their suppliers and other parties involved develop.

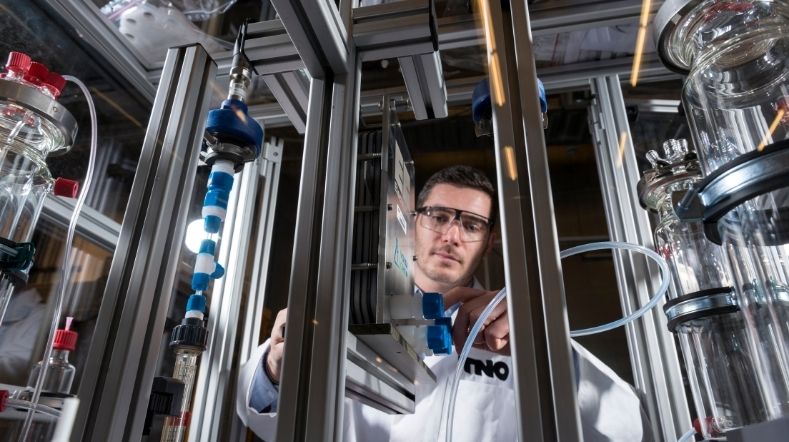

Customised solutions for a sustainable industry

That is why TNO works with partners and offers knowledge, innovation and concrete solutions for companies, government and suppliers. In a nutshell, we call this TNO Green Prints. A TNO Green Print is a blueprint for radical greening of your value chain in the industrial sector.

Customisation: from calculation models leading to new government policy, scaling up electrolysis, CO2 capture solutions for the chemical industry, designing circular products to technologies to recycle and reuse plastics.

All available knowledge, experience and innovations are processed in a TNO Green Print into a specific solution. In this way you can contribute to the acceleration of a clean industry in 2050.

Industrial transformation: sustainable value chains

Traditionally, industry has been accustomed to relying on fossil-based raw materials such as coal, oil and gas. Their operations and infrastructures have been based on these raw materials for decades. The challenge now is to transform the industry and find new ways towards a carbon free and CO2 neutral industry and to face out fossil energy supply and making a sustainable and green value chain. Manufacturing products using sustainable and renewable energy. The task is to ensure that industry can continue to make products but without harmful emissions.

The transformation to sustainability means that companies must operate in value chains other than those to which they are accustomed. Suppliers must provide sustainable raw materials and fuels. There are many uncertainties, such as the availability and supply of renewable energy and raw materials, new legislation, and changing market demands.

Webinar: CO2 reduction and green carbon in the industry from residual flows

Learn more about three unique technologies that convert carbon en CO2 into sustainable products.

How TNO Green Print accelerates a sustainable industry

We help to face this task by supporting governments in their policy development, and working together with the industry on technological solutions. In this context, we create so-called collaborative business models, knowledge and technologies which enable parties to establish new value chains. With our ‘Green Prints’, we offer clearly defined solutions to policy makers, managers energy transition in the industry.

- TNO has a solid foundation of expertise in the field of sustainable energy, electrification and production of hydrogen, CO2 capture and reuse raw materials.

- We work closely with companies and government, knowledge institutions and governments in Europe and beyond.

- New technology that will allow the capture and re-use of CO2 in the industry that was previously impossible.

- With technology to recycle and reuse plastics, we make it possible to make plastics circular.

- Our ambition for 2030: still this decade, TNO and its partners will succeed in making plastic from air and industrial residual gases in a Dutch factory.

Projects, papers and collaborations

Recently, we have been working together with industry and parties in projects and platforms to develop and upscale sustainable solutions for the industry.

To keep the energy transition feasible and affordable in the short term, it is essential to use blue hydrogen. Our SEWGS breakthrough innovation enables steel producers and refineries to cheaply and easily convert CO2 captured from process gases into blue hydrogen.

In addition to SEWGS, we also developed the SEDMES technology. We use it to convert captured CO2 with green hydrogen into useful by-products, chemicals and fuels (such as dimethyl ether).

Industrial thermal energy storage (TES) has the potential to make a major contribution to reducing the greenhouse effect. The majority of industrial energy demand consists of process heat, which is currently generated from fossil fuels. TES makes it possible to meet this demand using renewable energy. These are the conclusions drawn in a study by the European Energy Research Alliance (EERA), to which TNO made important contributions.

We’re working on several projects to make industrial heat management more sustainable. We’re doing this in collaboration with end users, suppliers, and other partners. Find out what projects we’re currently working on.

In the project SOLIDARITY, TNO and partners are working together to demonstrate cost-effective drying & dewatering in the process industry. They do this by combining technology and innovations in liquid-solid and liquid-liquid separations, leading to less use of heat, increased use of (clean) electricity and improved process efficiency.

Together with tech employers' organisations FME, Deltalinqs, the Port of Rotterdam Authority and InnovationQuarter, we established the Fieldlab Industrial Electrification (FLIE). FLIE offers companies practical support and clearly defined solutions for transitioning from fossil fuels to electrification.

In line with this, we are working with companies in the manufacturing industry to optimise electrolysers. This is done in the Electrolyser Makers Platform.

With our knowledge partner Forschungzentrum Jülich, we are developing a joint German-Dutch hydrogen market which has the potential to grow to seven times its current size by 2050. In the HY3 project, we are exploring new value chains with our partners. Hydrogen production on the Dutch and German North Sea will then be connected to large industrial clusters in both countries.

The transport sector is a major consumer of fossil energy. The proportion of renewable energy is only a few percent. European regulations require this to be 14% by 2030, of which 3.5% must be biofuels to provide affordable biofuels for road transport, shipping and, eventually, aviation.

From innovations for new plastic product designs to sustainable technologies to recycle plastics. TNO makes it possible to make the plastics we use circular.

To this end, we also develop system models with which we sketch future scenarios, such as our Plastics Recycling Impact Scenario model. With this, TNO has shown that, in an ideal situation, the Netherlands could be 87% circular by 2050.

Microplastics: much in the news, but there is still very little knowledge of exactly where they come from, how they are formed and what the risks are for humans and nature. The focus here is mainly on packaging, tyres and textiles.

Esther van den Beuken, TNO: 'Through research, we want to accurately characterise microplastics to identify the risks and counteract their formation. Ultimately, this is how we want to realise a society that is one hundred per cent circular.'

The transformation to a sustainable industry requires system changes. Our society faces major challenges from climate change, depletion of natural resources, loss of biodiversity and other threats. Collaborative business models support working on practical applicable methods to help coalitions of parties shape the transition.

Two scenarios illustrate a vision for energy supply in the Netherlands after 2030 and provide insight into the implications of the more stringent targets. They show how a climate-neutral energy system can be achieved by various sustainability initiatives. The starting point is the pursuit of an energy system at the lowest cost to society.

The energy transition must happen more quickly. For a number of dominant sectors, TNO indicates important options that could accelerate the current pace of development. It has also established which knowledge questions per sector still need to be answered. It is clear that the energy transition requires much more than only technological solutions. At least as important are costs, behaviour and the availability of professionals.

Now that the electricity and gas infrastructure is facing large-scale expansion and renewal, the government must be able to answer the many questions that may consequently arise. As an independent knowledge-based organisation, TNO advises and supports ministries, provinces, municipalities and regions in implementing effective policies. We also bring public and private parties together. As an orchestrator of innovation, we help government and industry to join forces. This requires more transparency from both sides. With our energy experts, economists, behavioural scientists and other disciplines, we offer all the knowledge required to help accelerate the sustainability of industry.

We work with government, suppliers and industry together in projects and platforms to develop and upscale technologies. Our aim is to make this possible within a few years, and on a large scale.

Get inspired

The North Sea as Europe's energy heart requires smart choices

Tomorrow’s hydrogen production and infrastructure: building towards a secure and robust energy system

World Hydrogen Summit 2025

Scaling-up electrochemical technologies for renewable ethylene production

CO2 infrastructure and transport