Old locks tell new stories

Safe operation of our hydraulic infrastructure cannot be taken for granted. With over 100 locks and weirs—many of them ageing—the Netherlands faces a complex challenge: how do we gain a complete picture of the maintenance required for infrastructure built over the past century? Together with Rijkswaterstaat, TNO is investigating construction methods, variations in concrete types, and regional differences in the design and construction of hydraulic structures.

The impact of a failed weir

‘In 2016, an inland vessel collided with the weir at Grave,’ says Johan van Sloten, Senior Advisor for Structural Hydraulic Engineering at Rijkswaterstaat. ‘The water level fell by three metres, leaving houseboats stranded in the mud, and shipping came to a halt.’ Johan illustrates what can happen if one of the more than 100 Dutch locks or weirs were to fail.

‘When you look at a lock, you actually see several networks coming together,’ he explains. ‘It’s not just a waterway for ships. There’s always a difference in water level, so it’s part of water management. The lock may also be part of a flood defence system. And often, there’s a road on top of it. So, multiple networks and interests converge in a single structure.’

Finding the right moment for maintenance

Whether it is collisions like those at Grave or, more recently, at the Borgharen weir, or the widening of the Julianakanaal, the economic impact can be considerable. Timely maintenance is therefore essential. Yet determining the optimal moment for maintenance is a complex puzzle.

‘A large part of our locks was built in the 1920s and 1930s, before the Second World War. After the war, there was another wave of construction,’ Johan explains. ‘Those structures are now between 60 and 100 years old. The question is: will they last another 10 years, 20 years, or perhaps even 100 years? You don’t want to be caught off guard, but for many locks, we simply don’t know exactly when intervention will be necessary.’

‘You don’t want to be caught off guard, but for many locks, we simply don’t know exactly when intervention will be necessary.’

Repairing rather than replacing

‘This has become essential, especially as we increasingly rely on preventive maintenance. In recent years, there has been a shift in how we view infrastructure maintenance,’ says Herdis Heinemann, Technical Lead at TNO and expert in historic concrete.

‘The current approach is to build less new infrastructure and focus more on extending the lifespan of existing assets. We can’t afford to rebuild everything, nor is it sustainable. We need to collaborate more intelligently and set priorities based on up-to-date information.’

Not all locks are the same

Why can’t you simply look at the year of construction to assess the condition of a lock? ‘If you make a rough selection based on age, you risk writing off well-functioning assets and overlook vulnerable structures,’ Herdis explains. ‘Many people think: concrete is concrete. But what they forget is that we are dealing with about 100 years of locks, alongside 100 years of concrete development.’

Herdis and Johan are delving into various archives to investigate. ‘We see all sorts of nuances,’ says Johan. ‘A lock from the 1920s in Limburg can differ greatly from one built in the same period in North Holland. In Limburg, gravel from the Meuse was used, whereas in North Holland, locally sourced dune sand was common. At the time, there was also a heavy reliance on foreign cements. So, the properties of the concrete can vary greatly.’

The differences go beyond just materials. The researchers observe significant regional preferences in construction methods, as well as geographical and economic factors that contribute to these variations.

Discover the Infrascan

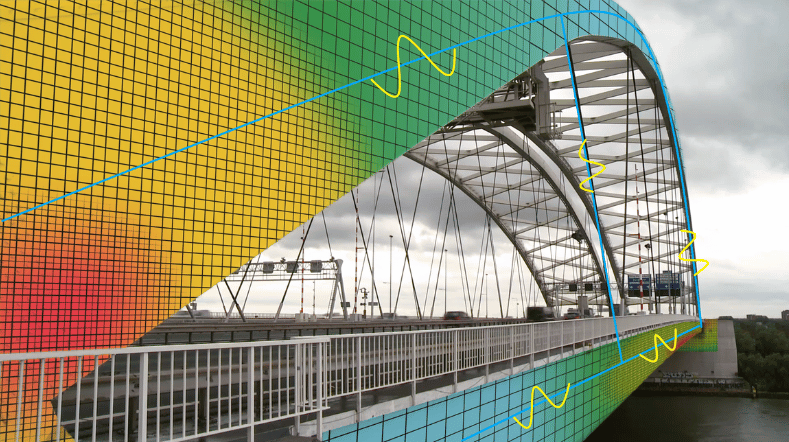

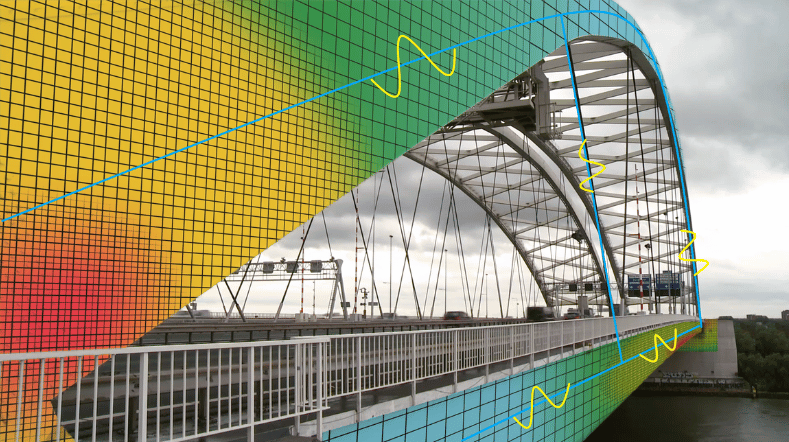

To help asset managers justify their renovation decisions, TNO, together with Rijkswaterstaat, is developing a promising tool: InfraScan.

Assessing what you cannot see

The easiest way to assess the condition of a lock is, of course, to inspect it directly. But this is easier said than done, Johan notes: ‘With a lock, you only see the part above the waterline. In some cases, you can lower the water level, but the backside of a lock wall is often inaccessible. For large locks, you are talking about depths of ten metres or more. Just getting there is a major operation.’

For this reason, TNO has launched a project in which locks are inspected during demolition. The oldest locks in the Netherlands, which are no longer fit for use, provide a wealth of information about how concrete ages and reveal the ‘blind spots’ that are normally impossible to inspect.

Disappearing knowledge

‘But you only benefit from this data if you know what to look for,’ says Herdis, who holds a PhD in historic concrete. And here lies a striking problem: the loss of historical knowledge. ‘Current training focuses on new construction. There is no course dedicated to 100 years of concrete history. Even the terminology has changed. If you read an old specification from 1920 without the right background, you overlook critical issues.’

This knowledge is crucial for accurate assessment. ‘If inspectors don’t know what to look for in a lock from 1920, they may miss critical issues. In practice, we see that engineers sometimes need extra guidance.’

‘Current training focuses on new construction. There is no course dedicated to 100 years of concrete history. Even the terminology has changed. If you read an old specification from 1920 without the right background, you overlook critical issues.’

In-depth collaboration leads to new insights

Ultimately, it’s the combination of different sources that helps build a complete picture: historical inspection reports, archives, or inspecting similar locks. ‘We want to recognise patterns so we can identify hydraulic structures that require extra attention.’

For this, TNO and Rijkswaterstaat are ideal partners, says Johan: ‘Rijkswaterstaat has the assets, the archives, and the concrete problems that need solving. TNO brings decades of experience in concrete and inspections, plus a fresh perspective.’

Herdis adds: ‘We have a broad range of expertise—people who carry out inspections, people who model, people who specialise in concrete. At TNO, we can zoom out from the asset level to the national scale and back again.’

‘Sometimes I share documents from our archive with TNO. We’re talking about 900 pages from 1928,’ says Johan. ‘You need to know which three pages are truly valuable. TNO has the expertise to identify those gems.’

Knowledge sharing is essential

Both experts have a clear message for other infrastructure managers. ‘If you’re working on this too, let us know. Share your knowledge,’ says Johan. ‘There are no competitors here. The more we share, the more we learn, and the better we can make things together.’

Herdis adds: ‘People need to realise that ‘old’ doesn’t automatically mean ‘demolish’. Old concrete is a different category of material that requires extra attention. Look at it with fresh eyes.’

‘Even when using innovative technical solutions and new inspection methods, such as laser scanning, knowledge of historic concrete remains crucial,’ says Herdis. ‘It’s of little use if you lack the fundamental understanding of history and concrete. If you do not know where to measure, why you are measuring, or what the results mean in the context of a 100-year-old structure, you will miss the point.’

Would you like to know more about the research by Rijkswaterstaat and TNO, or do you need advice or inspection of existing water infrastructure? Please get in touch.

Get inspired

Make informed decisions on maintenance and renovation with InfraScan

Building Materials and Structures

Predictive Twin Lab for the built environment

International recognition for TNO’s spin-off ‘SHM NEXT’ at 15th EARTO Innovation Awards

SHM NEXT: time travelling into infrastructure integrity with predictive twins