STEPWISE and FReSMe: CO2-reduction solutions for the steel industry

Status project

EU Horizon 2020 programme

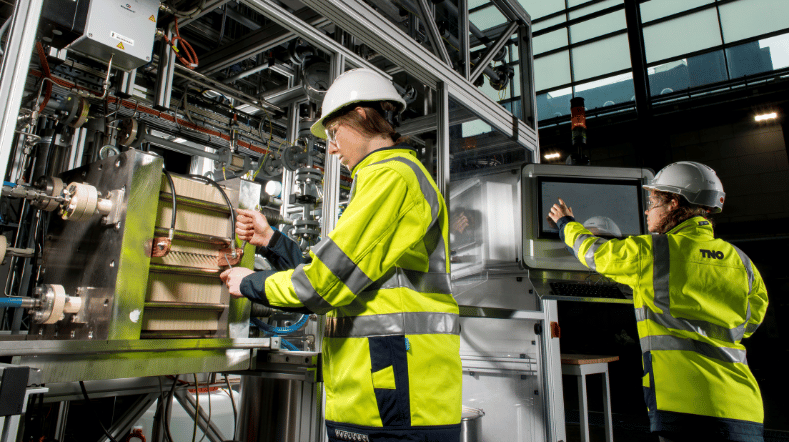

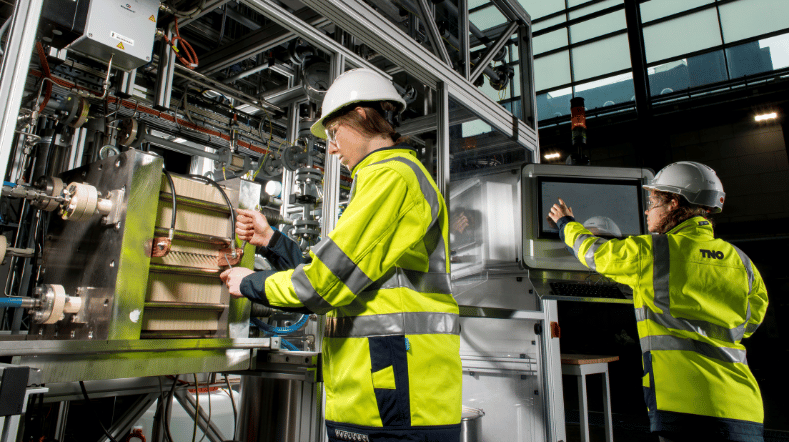

The STEPWISE and FReSMe projects demonstrate the cost effective CO2 capture from residual gases in the steel industry using advanced technologies y valorising the energy content of the blast furnace gas. Together with our partners, TNO operates a pilot plant with real industrial gas in Swerim, Sweden.

Together with our partners, TNO operates a pilot plant with real industrial gas in Swerim, Sweden.

STEPWISE and FReSMe

STEPWISE and FReSMe are two projects executed within the European Horizon 2020 program. The projects demonstrate TNO's advanced CO2 removal technology in the Iron and Steel industry, resulting at reduced CO2 footprint of steel production.

Real Blast Furnace Gas is used and decarbonized and subsequently used for power and methanol production. The CO2 removal is performed with TNO's advanced CO2 removal technology, making use of regenerative solid adsorbents.

The technology combines the conversion of the carbon monoxide into CO2 and H2 by reacting it with steam via the Water-gas shift reaction, with the adsorption of the CO2 on a selective solid adsorbent at elevated temperature.

Regeneration of the solid adsorbent by means of pressure swing results in CO2, suitable for transport and storage. In the STEPWISE project, this process is demonstrated at a scale of 14 t/day CO2 removal. The FReSMe project is producing 1000 liters of Methanol per day from the Blast Furnace gas that will be used as a ship transportation fuel.

These project have received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 640769 and No 727504.

Get inspired

Ten things to know about carbon capture and storage (CCS)

Unique test installation for CO2 capture and conversion to green chemicals

SEWGS: revolutionary CO2-reduction technology

Capturing carbon emissions

Award-winning excellence: CO2 capture applied