Smart windows make climate-neutral living more attainable

Sustainable innovations are crucial to achieving an energy- and climate-neutral built environment by 2050. TNO’s SunSmart smart windows can significantly reduce residential energy consumption. A thermochromic coating keeps solar heat out in summer and lets it through in winter. This enables an average household to save 5-9% on the energy bill.

There are more than 7 million buildings in the Netherlands, which together currently account for 40% of our energy consumption. The built environment also accounts for almost a third of carbon emissions. To meet the requirements of the Paris Climate Agreement, all homes and offices need to become substantially more sustainable.

The intended end result is an energy- and climate-neutral built environment by 2050, which will require innovations to help reduce energy consumption. In addition to solar panels and heat pumps, smart windows could soon start making a significant contribution to energy and emissions reduction.

Air conditioning and heating can be turned off more often

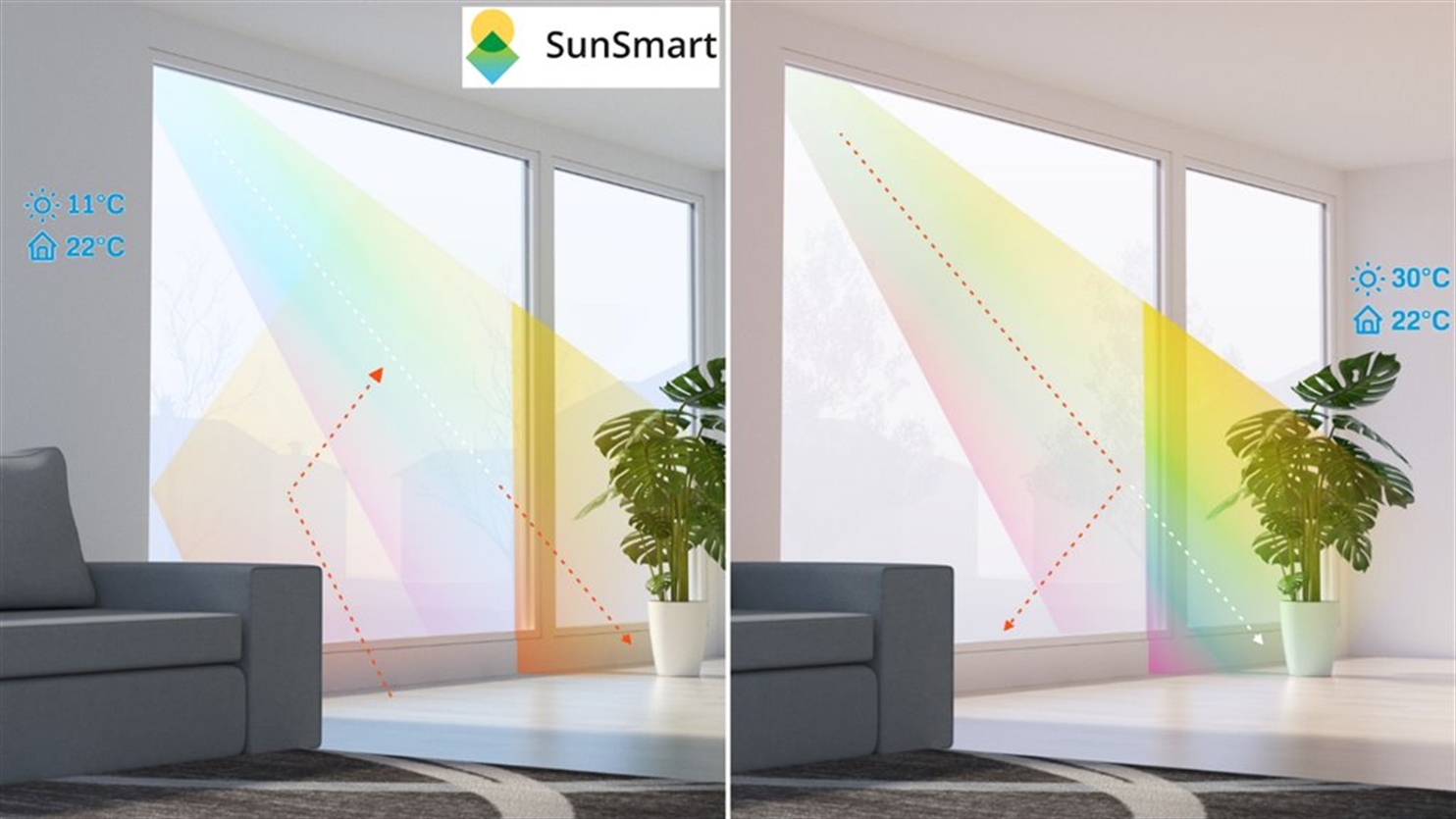

Brightlands Material Center, part of TNO, is currently working on the SunSmart smart window, which has a special coating. This thermochromic coating helps regulate indoor temperatures by blocking solar heat in summer and letting it through in winter.

As a result, smart windows can reduce the use of air conditioning and heating, and thus cut energy consumption. With this innovation, an average household could save around hundreds of euros (approximately €500) on energy bills.

Making windows smart

The special feature of the SunSmart smart window developed by TNO is that the thermochromic coating autonomously switches between letting in and blocking solar heat at a fixed temperature.

The SunSmart smart window’s ability to switch is an intrinsic feature of the coating material, which has been optimised for use in this application after years of research.

Advantages over existing solar control glass coatings

SunSmart windows, like solar control glass, block heat during the summer without altering the transparency or colour of the window. This results in energy savings on air conditioning, reduced heat stress, and greater comfort through both lower temperatures and ample daylight.

The major advantage over solar control glass is that SunSmart windows can adjust, allowing solar heat to pass through at lower temperatures (whereas solar control glass always blocks solar heat). This allows for optimal use of solar heat during other seasons, reducing the need for additional heating. The SunSmart smart windows, developed by TNO, are affordable and feature integrated temperature regulation. As a result, no extra (electrical) connections or replacement of window frames are necessary, increasing their applicability for architects.

This is how smart windows work

The smart windows feature a temperature-sensitive glass coating of vanadium dioxide mixed with other ingredients. Depending on the temperature, this layer either allows the sun’s infrared light to pass through or blocks it.

If it is colder outside than 21 degrees, the smart window allows solar heat to pass through, so the heating system does not have to work as hard. If it is warmer outside, the coating blocks thermal radiation. It then stays more comfortable inside and the air conditioning does not have to be turned on as often.

The smart window therefore offers benefits in all seasons. The thermochromic coating is primarily designed for temperate climates in large parts of Europe and the US.

Affordable innovation

While developing the smart windows, TNO explicitly considered the affordability of the raw materials as well as the production process. As a result, SunSmart thermochromic windows have a payback period of 5 to 7 years. This is roughly comparable to the investment in solar panels.

According to TNO, air-conditioned homes could save around 500 euros a year on their energy bills thanks to thermochromic windows. Another sustainable feature is that the windows are also durable, with a guaranteed service life of 20 years.

Other applications

Since we can also apply the thermochromic functionality in various polymer matrices, multiple applications are possible beyond just coated insulating glass. By adding thermochromic pigments to a polymer film, laminated windows (safety glass) can also be equipped with SunSmart, as well as retro-fit films for existing glass or use in polycarbonate sheets, for example.

From pilot line to large-scale production

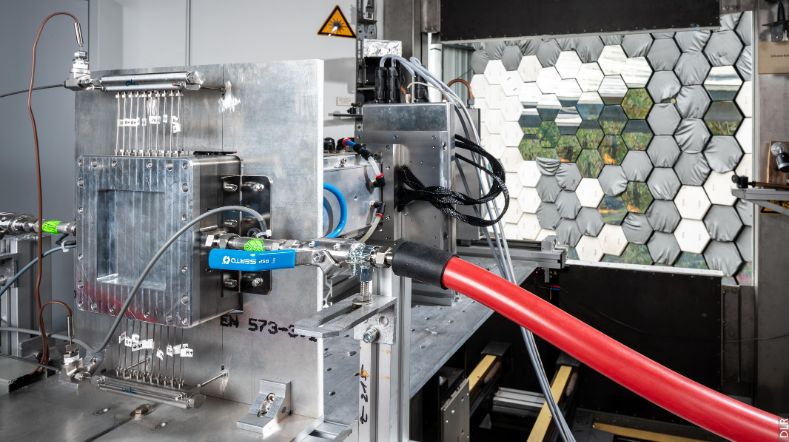

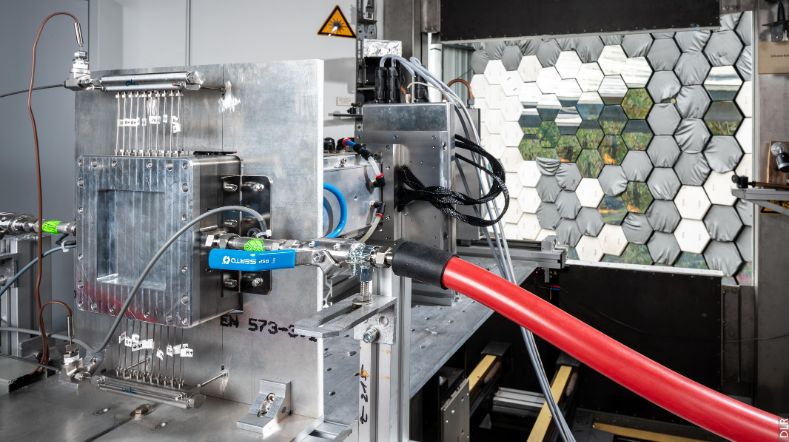

To test the performance, two prototype windows with the SunSmart coating and two standard windows were installed and tested at TNO's SolarBEAT test facility.

For a year, the radiation passing through the windows was measured with special equipment. These measurements showed that the SunSmart windows effectively switched between allowing and blocking heat, depending on the temperature.

We also won the Encouragement Award of the Dutch Glass Award 2025.

Thanks to the positive results and feedback from potential customers, we will prepare the spin-off technology as an independent company for the European market in 2025. We see great potential in new construction and renovation of windows to reduce heat stress in buildings and thus create more well-being for users.

Do you want more information about the possibilities, or a demonstration of the pilot line in Geleen?

Get inspired

VoltaChem Year Event 2025

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale

Time setters: Smart windows bring climate-neutral living a step closer