Research facility for industrial electrification

Electrification is a spearhead for making industry more sustainable. For example, the Rotterdam-Moerdijk port industry cluster is a major consumer of energy and causes almost twenty percent of CO2 emissions in our country. In order to accelerate the transition from fossil sources to electricity and green hydrogen, existing technologies must be taken to a higher level more quickly. The research facility Industrial Electrification will play an important role in this.

The Field Lab Industrial Electrification (Dutch only) (FLIE), is a mutual initiative of Deltalinqs, Port of Rotterdam, InnovationQuarter, FME and TNO in close cooperation with the EFRO funding, local authority Rotterdam and the province of South Holland.

TNO is responsible for the investment and will also scale up part of the developments in the international shared VoltaChem innovation programme in the central hub of the facility.

Demonstrations in practice

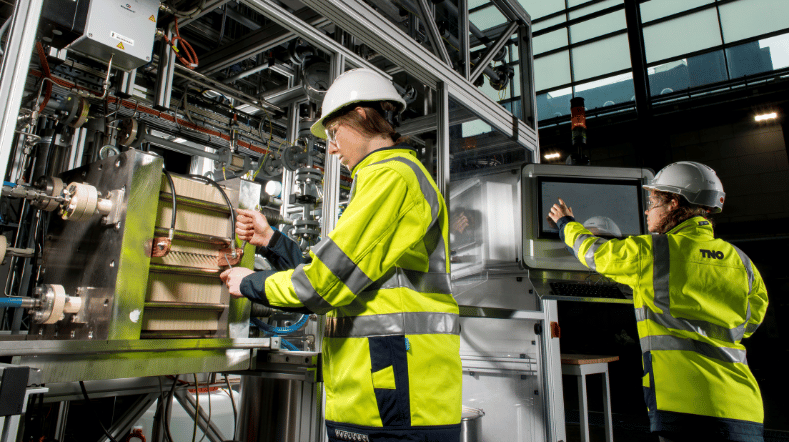

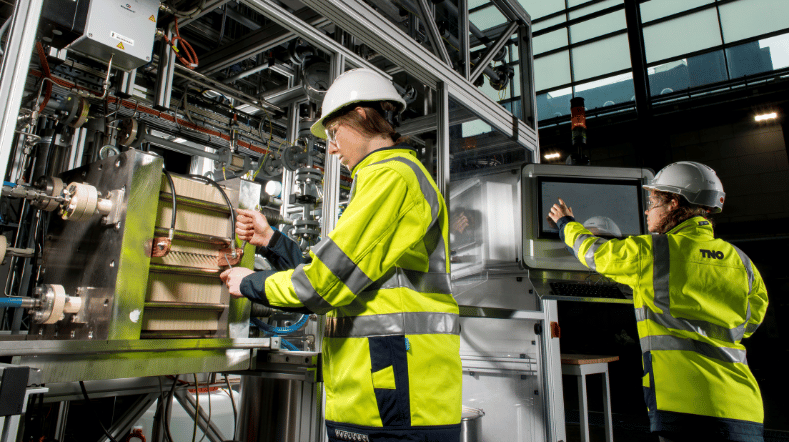

The research facility will contain three types of cluster-aligned installations that can be demonstrated in practice. These concern techniques in the field of industrial heat, integration of green hydrogen and direct conversion of CO2, all using sustainable electricity. Manufacturers of equipment and installations can demonstrate the operation of their latest heat pumps, electric boilers, electrolysers or conversion processes to potential customers as the final step towards market introduction.

The special feature of the facility is the ability to fit newly developed equipment into existing installations. This also makes the initiative unique: the infrastructure forms the link between the development labs of manufacturers and knowledge institutes themselves with industrial practice.

From prospect to reality

The facility focuses on the integration, demonstration and improvement of electrification technologies, such as heat pumps (Power-2-Heat), high temperature heat storage, electrolysers (Power-2-Hydrogen) or green hydrogen conversion processes (Power-2-Chemicals/-Fuels) in realistic conditions.

In the coming years, these technologies must be propelled from prospect to reality. For the market, the risks are still too great to finance such a lab itself. Sectors and stakeholders are also too diverse to tackle this jointly. This initiative by these partners, with national and regional authorities as the driving force, will break down this barrier.

Bringing interests together

The research facility brings innovative manufacturers from the FME grassroots together with Deltalinqs companies in the port area to use new equipment that enables production processes to be made more sustainable. Common interests are evident here.

Market research among a large number of parties has shown that there is a need to combine knowledge and practical demonstrations around industrial electrification. The facility is open to the manufacturing and industrial companies that want to become greener, and to research institutes.

New business and employment

The main objective of the Field Lab Industrial Electrification is to accelerate the electrification of industry in order to drastically reduce CO2 emissions. As a result, it will also contribute to new sustainable business activity and high-quality employment through the innovations it will generate.

A third advantage is that the Rotterdam port area will once again become more interesting for international parties to demonstrate their products here or to locate here.

Get inspired

Ten things to know about carbon capture and storage (CCS)

Unique test installation for CO2 capture and conversion to green chemicals

SEWGS: revolutionary CO2-reduction technology

Capturing carbon emissions

Award-winning excellence: CO2 capture applied