Discover TNO

Creating impactful innovations for the sustainable wellbeing and prosperity of society.

Our latest developments

668 resultaten, getoond 1 t/m 5

Japanese DNP opens Dutch R&D hub in partnership with TNO

DNP and TNO are opening the very first international R&D hub of the Japanese technology company at the High Tech Campus in Eindhoven.

TNO’s Unit Defence, Safety & Security strengthens ties with South Korea

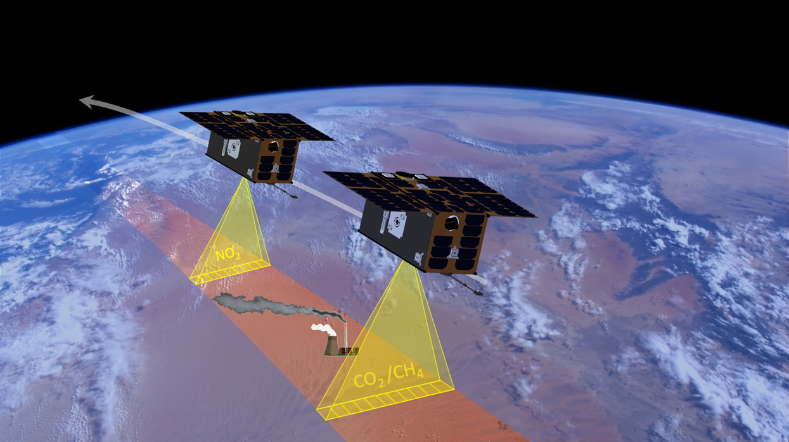

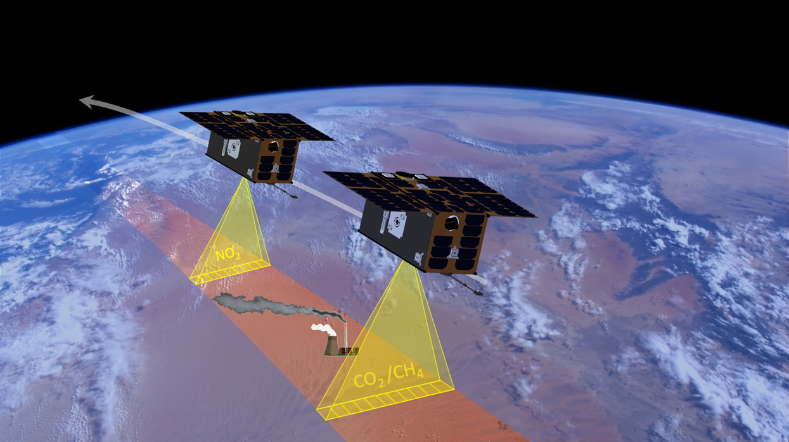

Dutch partners announce construction of climate satellite TANGO

3D pharma printing: Personalised medicine begins here

Early results show the potential of circular healthcare plastics

Contact us about your R&D challenge