High Tech Industry

The Dutch high-tech sector is a research and development hub that plays an essential role in European and global solutions to society’s greatest challenges. From advances in healthcare to sustainable energy, from increased security to mitigating climate change. TNO High Tech Industry works with local, regional, and international partners to enable effective, sustainable, and revolutionary technological innovation.

A partner in change

TNO High Tech Industry adapts to the ever-changing needs of the highly competitive Dutch high-tech sector. In the early 2000’s the focus was primarily on consumer electronics. Today, it is the manufacture of semiconductor equipment that enables innovation. And in the near future, advancements in integrated photonics, quantum technology and AI will require another shift in focus and innovation to keep the Dutch sector competitive. At the same time, societal challenges are driving the need for technological innovation in healthcare, sustainable energy, and manufacturing. Amidst this competitive landscape, rising geopolitical tensions are increasing the need for open strategic autonomy, technological sovereignty and production reshoring.

Dutch high-tech companies are poised to play a pivotal role in the development of key enabling technologies. They will not only contribute to prosperity in the Netherlands, but also enable Europe to maintain its competitive advantage in the global high-tech landscape and, of course, address some of the most complex challenges of our time. TNO High Tech Industry is positioned to support and accelerate their work by stimulating innovation and identifying and creating market opportunities.

High-tech industry in 2040

By 2040, a successful Dutch high-tech industry will generate around 50% of its revenue from newly created value chains. Download TNO’s whitepaper, which outlines how TNO will contribute to and advance these value chains.

TNO offers knowledge, insight, and innovations in future technologies that support the Dutch and European high-tech sectors. In a variety of (international) public/private partnerships and consortia, we contribute to a sector that will thrive and grow in the years to come, and ensure the Netherlands remains a leader in both existing and future industrial value chains.

Our work is divided amongst five business segments:

Future electronics

By leveraging flexible electronics, 3D hybrid printing and digital manufacturing, TNO develops systems and technologies that will advance existing and new value chains in energy storage, accelerated drug development, digital healthcare, advanced chip packaging, integrated photonics, and personalised food and pharma solutions.

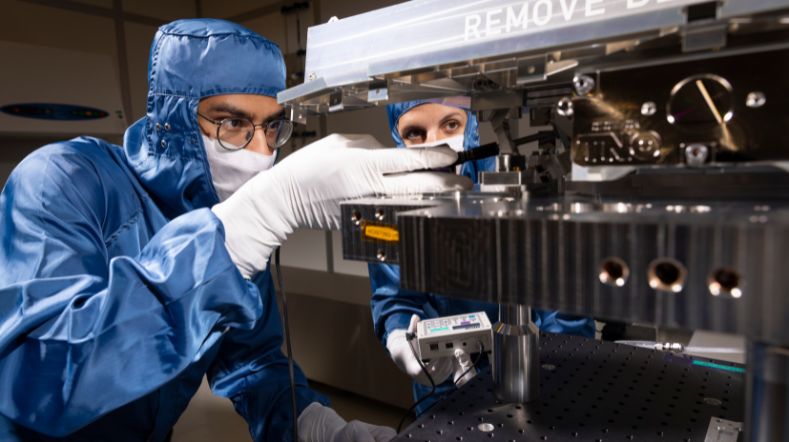

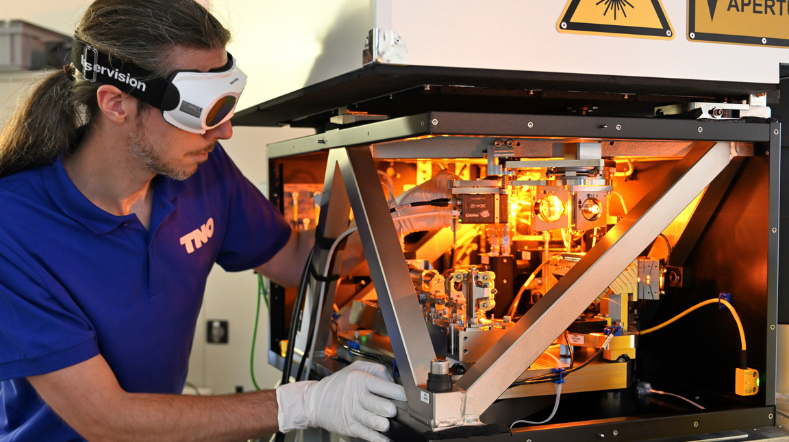

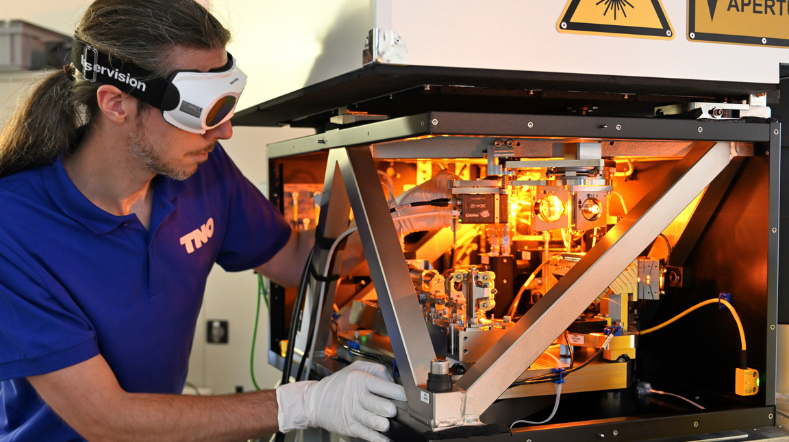

Semicon and quantum

The rapid development of quantum technologies will revolutionise computing, sensing, and diagnostic capabilities. Technologies like photonic integrated circuits, acoustic metrology, chip cooling, and tissue optics will bring new innovation leadership to the Dutch industry, and TNO will contribute to it all.

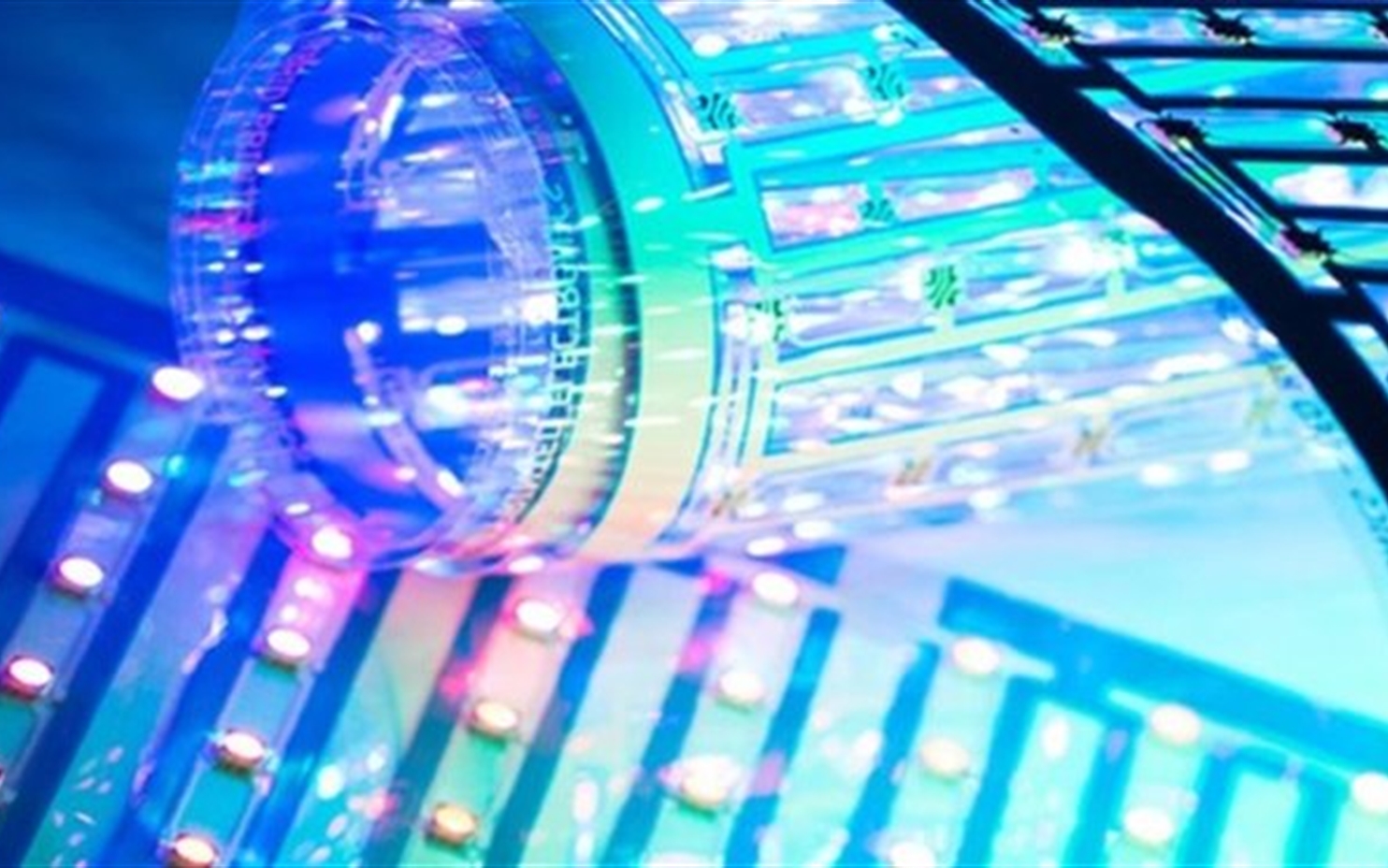

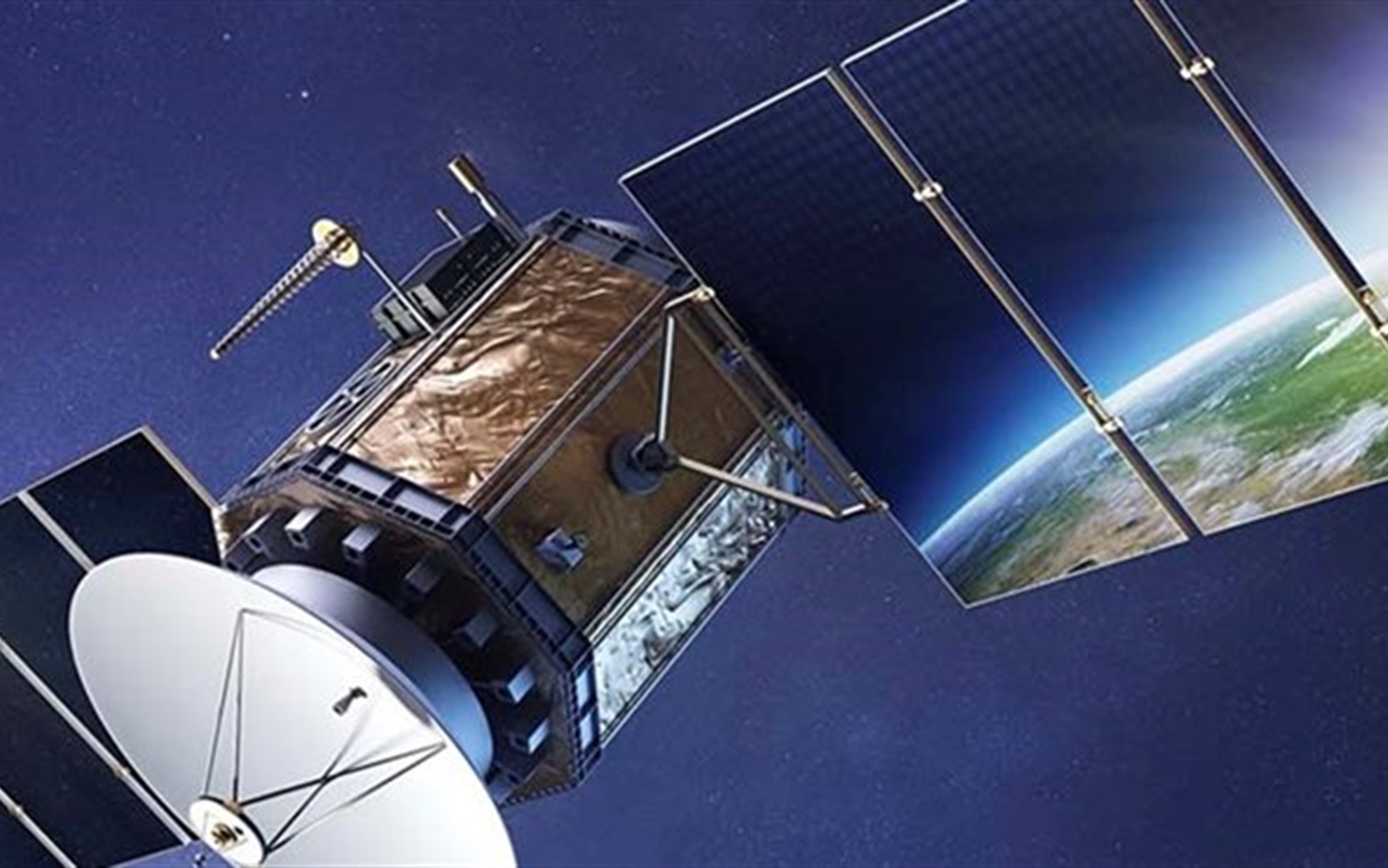

Space and scientific instrumentation

Laser and satellite technology are the key to monitoring and mitigating greenhouse gas emissions, expand secure broadband connectivity, enable a quantum internet and advance global defence systems. TNO’s decades of expertise in optical, optomechatronics and radar systems contribute the ground-breaking technologies and systems of the future.

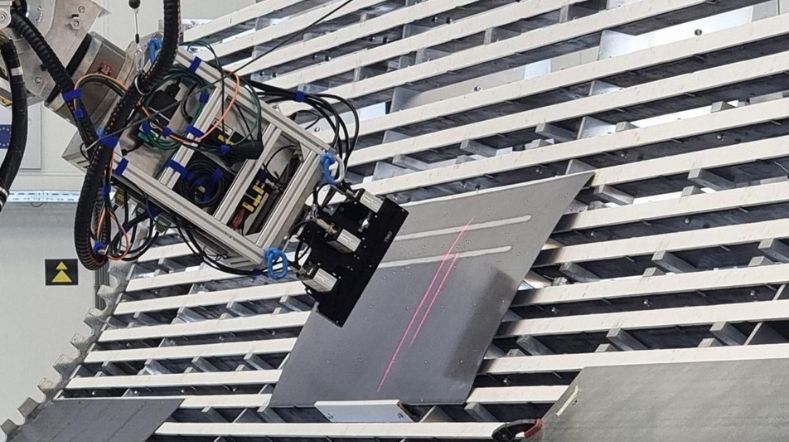

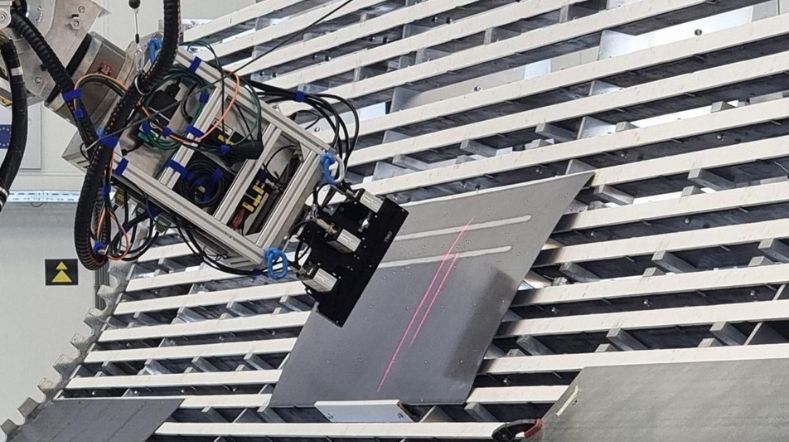

Smart manufacturing

Addressing critical societal challenges and securing European strategic autonomy requires circular production processes and hyper-efficient and resilient digital supply chains. TNO develops equipment and fabrication engineering technologies that will support the transition to a flexible, sustainable, and digitally connected European production network.

Small- & medium-sized enterprises (SMEs)

TNO’s Fast Track programme, start-up accelerator and strategic partnerships strengthen the competitiveness of SMEs and accelerate and de-risk their innovation processes. A true R&D partner, TNO aims to enable SMEs to contribute to key innovations, stimulate job development, and add maximum value to high-tech industries.

Research groups

Get inspired

Optics

Time setter story: Nienke Dijkstra

Non-destructive inspection

Semicon equipment and metrology

Space systems engineering