High-end Optics Manufacturing

Central to the functionality of numerous scientific instruments are optical components. Encompassing spectrometric and imaging optics vital for diverse applications such as scientific research, astronomy, lithography, and space exploration. TNO Optics Manufacturing stands as a prominent expertise center specializing in the manufacturing and qualification of intricate optical components and coatings.

Our commitment extends to delivering cutting-edge solutions tailored for complex optical systems, catering to high-stakes markets like space exploration and the semiconductor industry. As the landscape of instrument development evolves, demanding ever-reduced shape tolerances and surface roughness in optical components, TNO remains at the forefront, dedicated to the continual enhancement of our processes and facilities.

Technologies

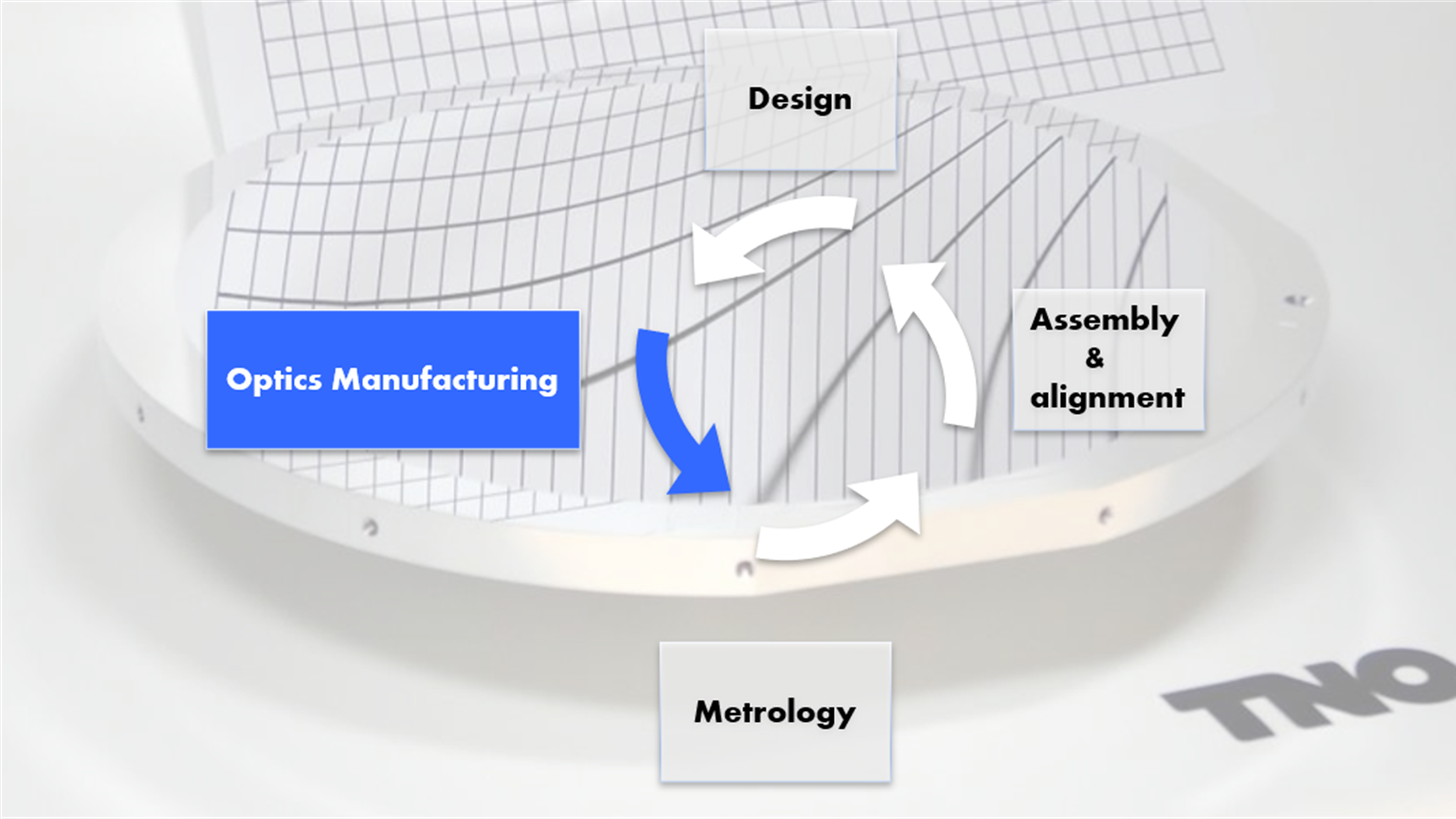

Our optical manufacturing experts focus on experimental research and the manufacturing of high accuracy and low roughness optics, in a completely in-house production process also including design, metrology, assembly, alignment and calibration of instruments.

Glass optics procurement for High Tech Industry projects

Optical components are vital to advanced applications in science, astronomy, lithography, and space exploration. TNO combines expertise with strong supplier partnerships to deliver specialised, high-quality optics tailored to unique project needs. Within the Glass Optics Procurement group, we bridge internal projects and the supplier chain to meet exacting standards. This booklet illustrates our capabilities through examples of complex, precision-engineered components.

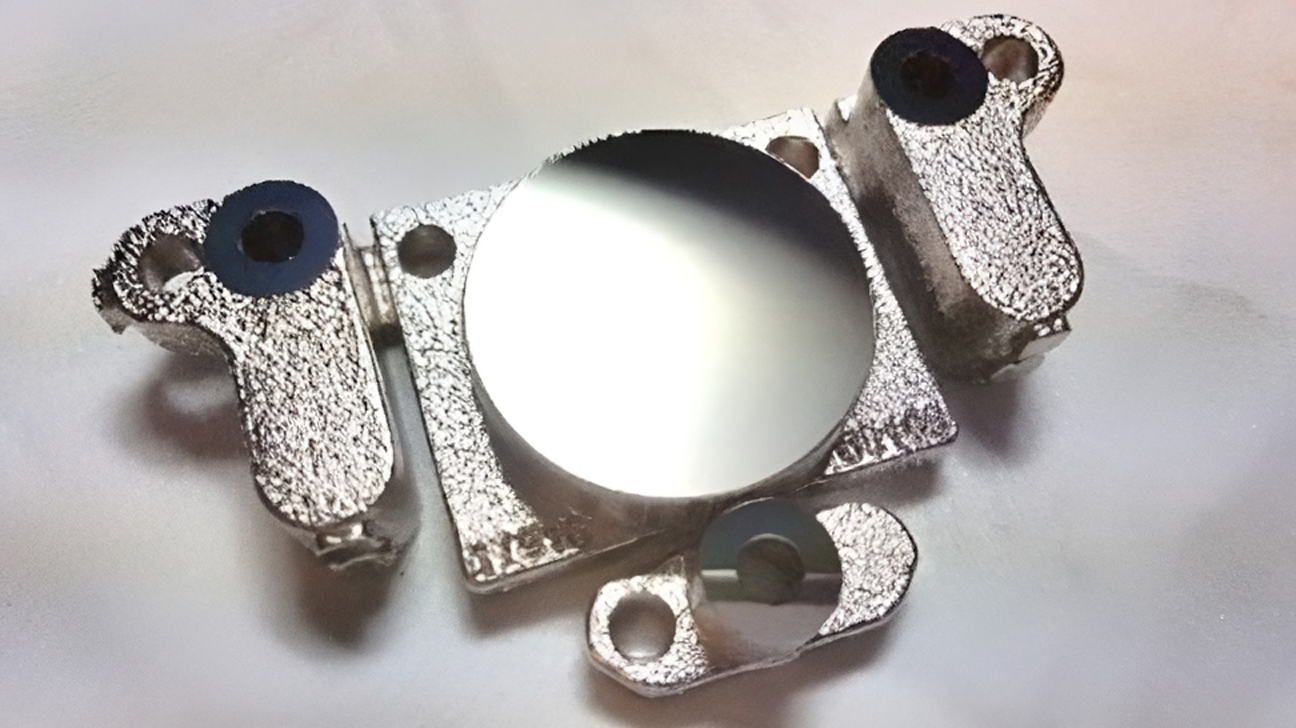

Single Point Diamond Turning (SPDT)

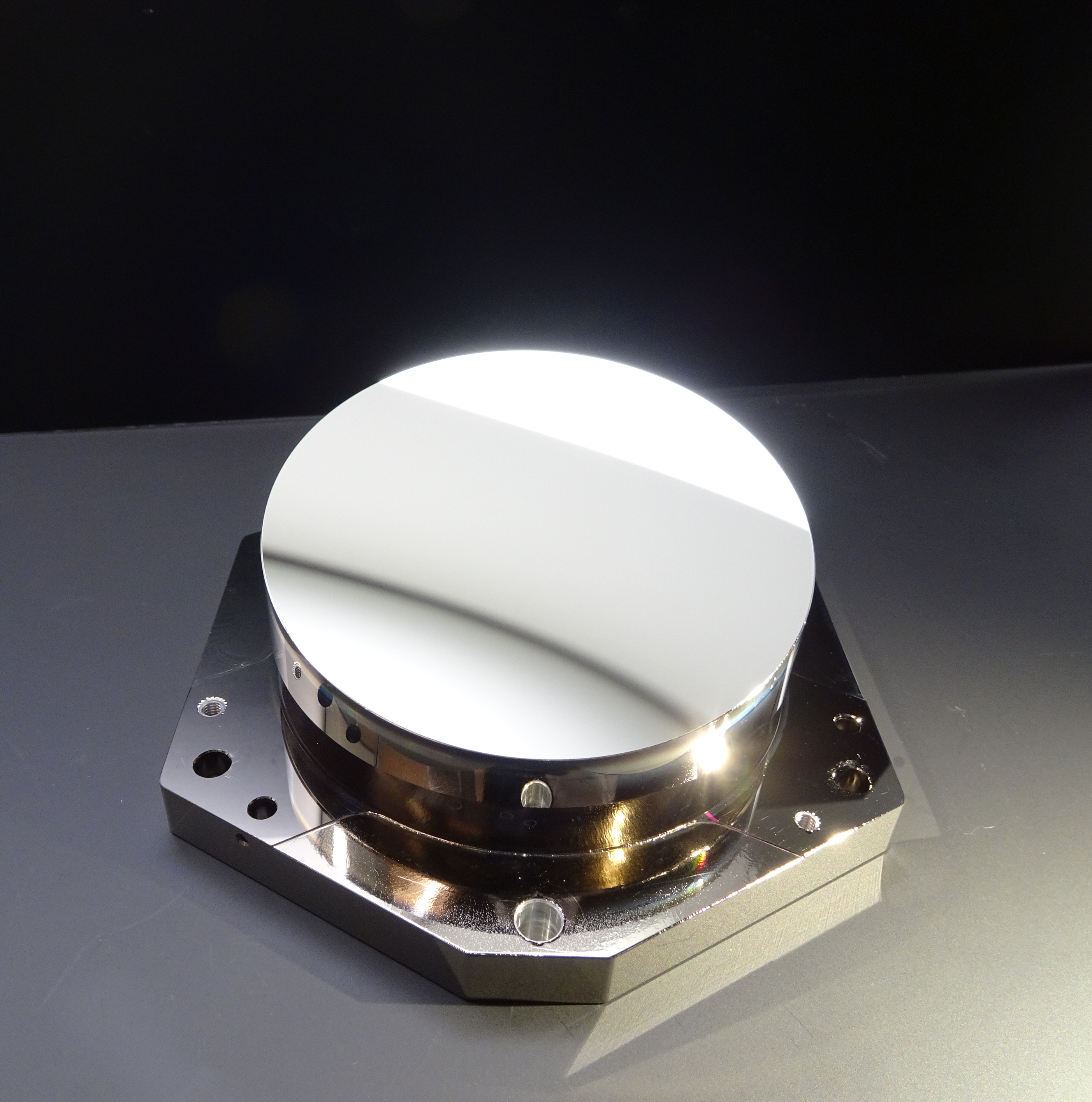

TNO's ultra-precise diamond turning lathes are able to machine both spherical, aspherical and freeform optical components into non-ferrous metals, crystals, polymers using diamonds. Our suite of machining processes include on-axis and off-axis diamond turning, flycutting and raster flycutting, 3D freeform slow tool servo, fast tool servo, grooving (lattices, gratings) and micro milling with Levricon highspeed spindle. We use these in combination with Magneto Rheological Finishing (MRF) resulting in ultra-low roughness and shape error.

Using different types of freeform metrology we measure the surface quality; the metrology data is fed back to SPDT and MRF processes to close the loop of machining and measuring. This results in freeform mirror components with maximum diameter of 600 mm, surface form error below 10 nanometer (RMSi) and roughness below 1 nanometer (Sq) .

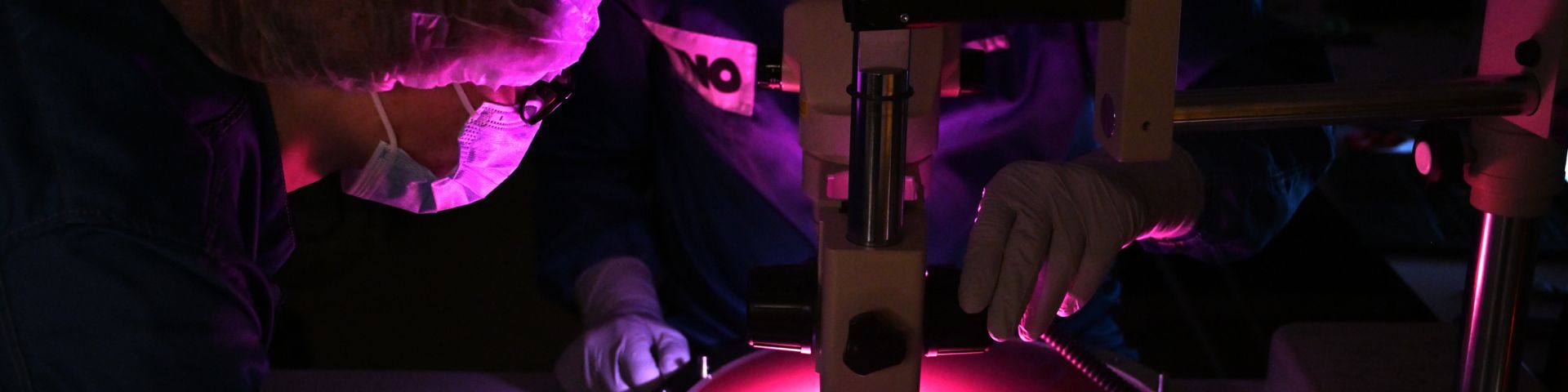

Coating

TNO Optics Manufacturing specializes in the development of application specific optical coatings. We routinely develop coatings that have specific requirements on reflection or transmission in various spectral bands, ranging from ultraviolet to short wave infrared. We provide you with solutions for optical coatings: from advice on feasibility in the concept phase of an instrument, to the design, development, qualification and production of the coatings. For this purpose we are equipped with three state-of-the-art e-beam evaporation systems and we have in-house facilities for testing and inspection according to the relevant ISO standards.

What I like about this group is that at Optics Manufacturing we are able to connect the world of dreams and the world of reality. Our products help humanity understand the world around us in a way that we could only dream of before.

Products

Freeform optics are applied more and more, because the functions of a set of conventional (spherical) components can be combined in a single freeform. At present we focus on developing freeform mirrors, including coatings.

The mechanical, thermal and dynamical aspects like mounting references, light weighting and thermal stability, are taken into account using integrated design and manufacturing processes. Standard coatings for UV, visible, and infrared can be produced, and we develop and qualify dedicated coatings for special requirements. For the production of glass components we cooperate with specialized partners from around the world. The final finishing of glass components can be done by using our MRF equipment.

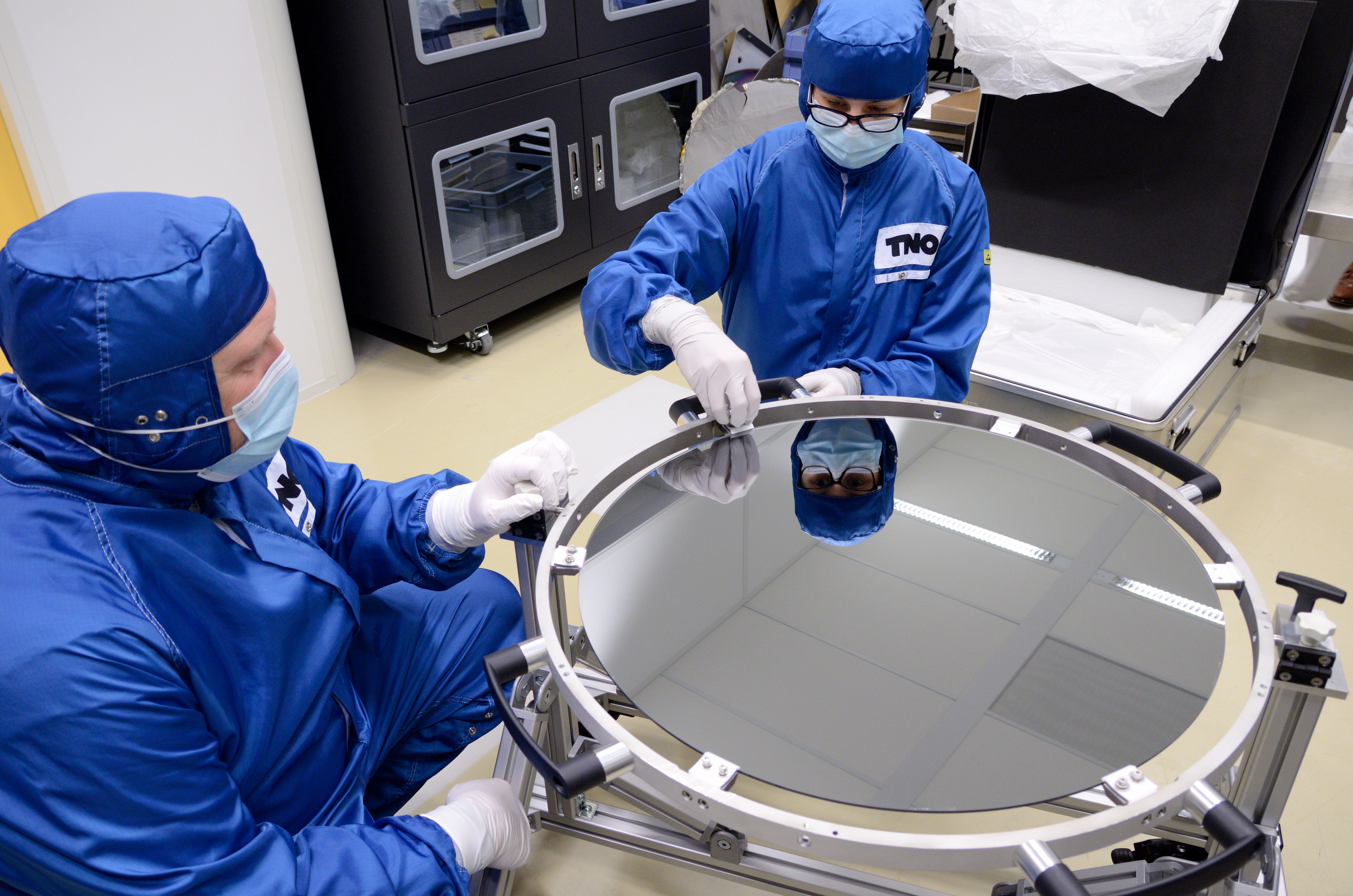

Equipment and Facilities

TNO has a state of the art lab (VLL) where we cooperate with TU Delft and leading national and international companies. The lab is packed with cleanrooms, with special temperature control and low-vibration structure. In house we developed special metrology system, component cleaning methods and tooling development.

4 Precitech machines for ultra-precision machining: Nanoform 350, Nanoform 700Ultra, Nanoform 700Freeform 5 axis, Nanoform NFX 250. Maximum capacity air bearing spindle up to 700 mm diameter. Fast Tool Servo FTS 5000, Levricon High Speed Spindle, Slow Tool Servo, on-machine metrology.

QED 300 with corrective polishing for improvement of shape error and roughness, for surfaces in metal, glass and glass-like materials, with diameters up to 300 mm.

Our team uses the electron beam evaporation and thermal evaporation methods as physical vapor deposition. There are 3 Evatec box-type coating systems which are called EVO and 640 machines with piezo-crystal based layer thickness monitoring. One of the systems is equipped with optical broad band monitoring. In the EVO machines, an ion assistance system can be used during evaporation to create denser plasma environment. With these systems, it is possible to perform high reflection mirror, anti-reflection, dielectric, dichroic, filter coatings and more.

DUI NMF600S for contactless surface form measurements from flat to freeform surfaces, with measurement volume ɸ600x125 mm. ASI (Q) stitching interferometer for surface form error. Bruker NPFLEX white-light interferometer for roughness measurement, Zeiss CMM Prismo Ultra for sub-micron dimension metrology, with 3D-measurements in a maximum volume 900x1200x650 mm. Zygo interferometer Verifire 1000. Perkin Elmer lambda 1050 TAMS spectrophotometer for spectral measurements, Sentec 850 Ellipsometer for coating polarization metrology.

Before we can coat products in our coating machines, we need to be sure that products are cleaned to our standards. Using our in-house developed cleaning methods, we will make sure that dust levels and overall cleanliness are ensured. In this process we use techniques like mega-sonic cleaning and CO₂-cleaning.

Applications of high-end optics

TNO develops instruments, subsystems and components for a broad range of markets:

- Space: satellite instruments and earth observation, laser satellite communication and space science. Recent trends are small satellites and cubesats.

- Astronomy: instrumentation and adaptive mirrors for ground based telescopes.

- Semicon: prototype components for lithography and metrology machines.

- Industry

- Quantum

- Defense

- Medical