Report: Drop-in solutions as an accelerator of biobased chemistry

Commissioned by and in collaboration with TKI Energy and Industry, TNO has prepared a discussion paper on the potential of drop-in routes in the feedstock transition. Not as a replacement for the necessary investments in biobased alternative chemistry, but rather as an acceleration of them. The first part of the paper outlines the challenge and invites further discussion. This forms the basis for a case study in the second part of the document.

Drop in solutions: an accelerator for the transition to biobased chemistry?

The Dutch chemical industry faces a major challenge: achieving climate neutrality by 2050. In addition to reducing raw material use, improving production efficiency, and closing material loops, the shift toward renewable feedstocks also plays an important role.

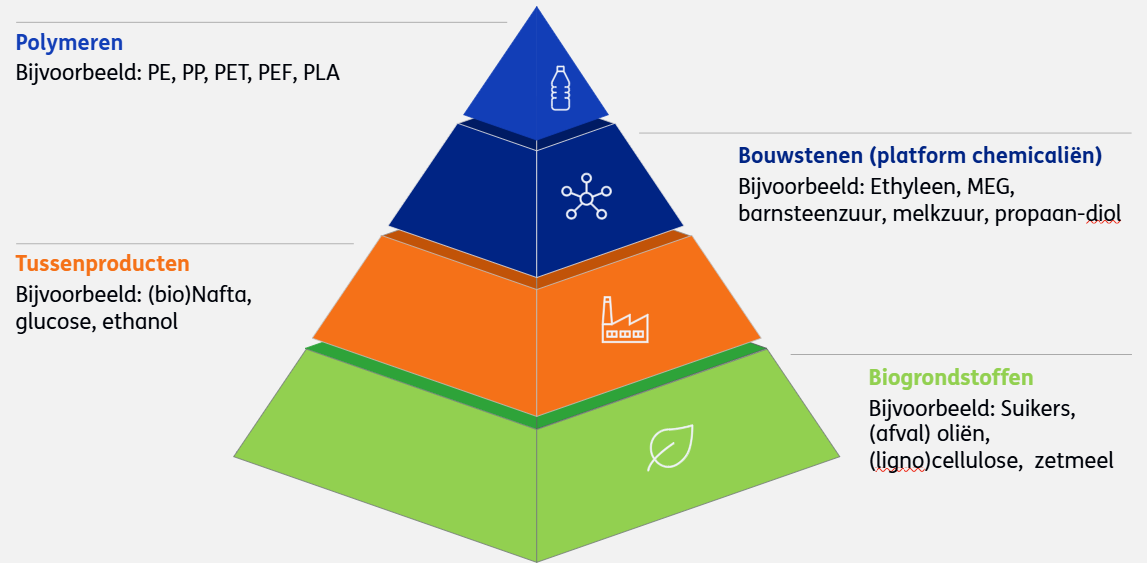

Fossil resources are being replaced by renewable alternatives such as biomass and CO₂. Alternative biobased chemicals are key in this process: they make efficient use of the chemical structure of biomass, can be produced with lower energy input, and often offer new functionalities, such as biodegradability.

Alongside this, there is growing interest in drop in biobased chemicals. These are identical to their fossil counterparts, enabling a gradual transition in feedstocks without major system changes.

But how can these conventional materials help bridge the transition period? And how do you make well informed choices about feedstocks and technologies that are both sustainable and economically viable?

Stay informed: receive the discussion paper as soon as it’s released

Discover how this approach can support companies and policymakers on the path toward a climate‑neutral chemical industry.

A case study: comparing six selected drop in routes for biobased ethylene production

The second part of the document presents a case study illustrating how decision making around feedstocks and technologies can be approached. TNO applies the three step framework to six potential drop in routes for producing biobased ethylene.

This demonstrates how the framework can support the initial identification of routes that merit further analysis, as well as guide strategic choices for the sustainable transformation of the chemical industry.The selected routes are compared based on an initial screening of environmental impact and economic feasibility.

The aim is to show how such an early assessment can help identify promising feedstocks and technologies that can advance the transition.

Want to know more? Ask your questions in our webinar

TKI Energy and Industry is organising a webinar on this topic in collaboration with TNO on 11 February. During the webinar, we aim to further explore the topic together with industry stakeholders, policymakers, and other interested parties. TNO will present the results of the case study as described in the discussion paper.

TKI Energy and Industry supports entrepreneurs and researchers in developing innovations that contribute to a more sustainable industry. The topic of drop‑in solutions currently receives relatively little attention in the discussion on the materials transition, even though it can be an important building block for accelerating the transition.

The webinar is part of the innovation programme Feedstocks and Products for Circularity.

Sign up for the webinar on 11 February

During the webinar 'Drop-in solutions in a Dutch bio-based chemical industry' - Quick scan on ethylene as proxy to inform policy making', we aim to further explore the topic together with industry stakeholders, policymakers, and other interested parties.

Get inspired

Nieuwe routes voor sortering en composietscheiding

HyFINE: Pionier in duurzame routes voor speciale en fijne chemicaliën

Van lab naar markt: TNO versnelt duurzame plasticrecycling met dissolutie

Biobased weekmakers

Microplastics in kleding