Ontdek TNO

Impactvolle innovaties creëren voor duurzaam welzijn en welvaart van de samenleving.

Volg de laatste ontwikkelingen

1074 resultaten, getoond 1 t/m 5

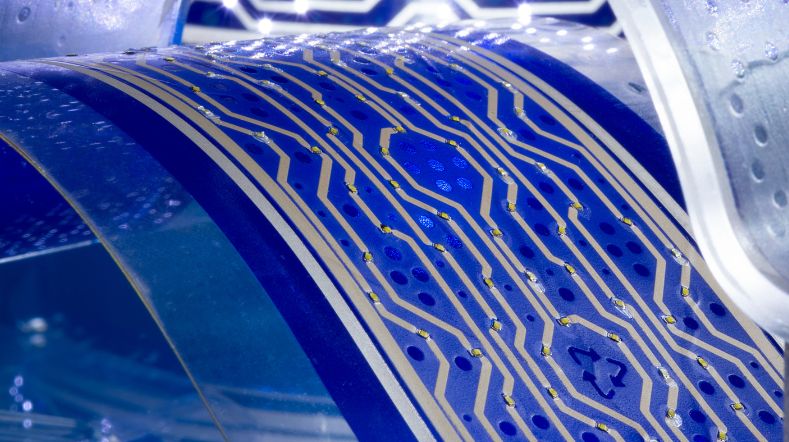

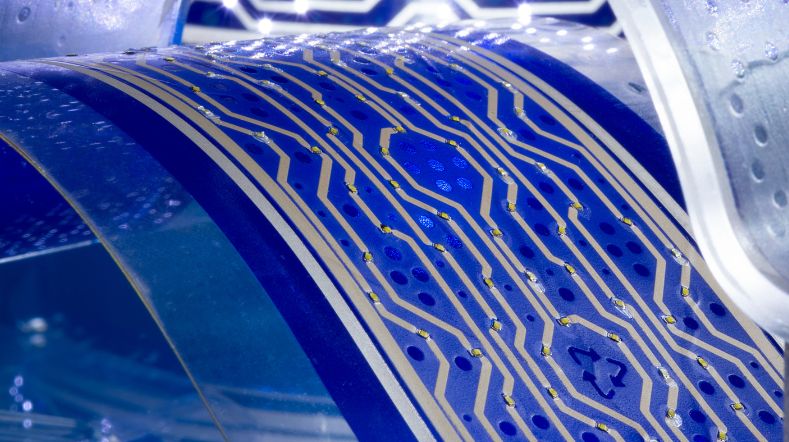

TNO ontwikkelt eerste methode voor volledig circulaire elektronica

TNO ontwikkelt nieuwe methode om electronica beter de kunnen recyclen na levensduur.

Dit is onze tijd

TNO maakt luchtkwaliteit rondom vliegvelden inzichtelijk

Thuiswerkers wonen kwartier verder van werk

World Hydrogen Summit 2024

Vrijblijvend sparren over jouw uitdaging?