Nearfield Instruments: world leader in metrology

In its 2015 annual report, TNO presented it as a showcase: nanofabrication and quantum computing. The production of the new generation of superfast computers will soon require completely new technologies and processes. Then, continuous measurement during the production process is essential to prevent errors. The spin-off Nearfield Instruments will realise revolutionary systems for this purpose.

Learn more about Nearfield Instruments

Powerful and energy-efficient

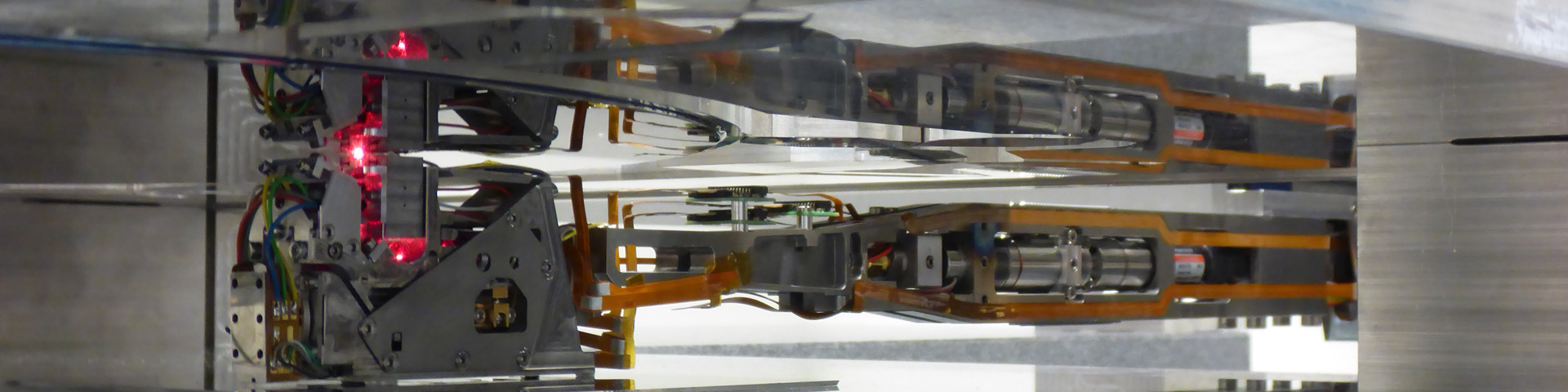

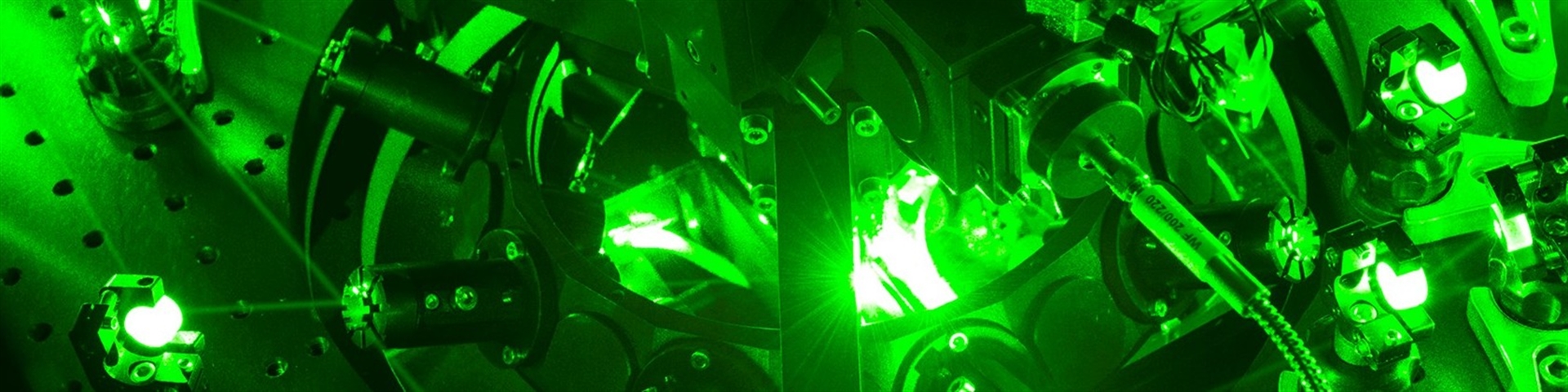

In the first instance it concerns the development of metrology systems for the semiconductor industry. This technology, high throughput scanning probe microscopy (HT-SPM), will enable the industry to continue to produce increasingly more powerful and energy-efficient electronics at lower costs. Nearfield Instruments is a global leader in this field.

In this video Hamed Sadeghian and Roland van Vliet show how with the help of High Throughput Scanning Probe Microscopy the quality of chips can be checked.

A thousand times faster

The company was started in early 2016 by two TNO employees whose activities are the result of the TNO programme; Nano-OptoMechatronics Instrumentation. The programme was set up earlier to provide the semiconductor industry, among other things, with new techniques and applications. In just a few years, TNO experts managed to make SPM technology a thousand times faster and Nearfield Instruments is now bringing these solutions to the market.

High expectations

After successful demonstrations with a Proof of Concept to large chip manufacturers, there are high expectations and this has therefore attracted large investors, with Samsung Venture Investment Corporation, the VC branch of Samsung Electronics, and Innovation Industries, an investment fund for high-tech innovations in the Netherlands, jointly investing ten million euros. TNO remains affiliated to the company as a shareholder.

New generation

Of course, every semiconductor production process is under strict control, but the Nearfield Instruments metrology systems raise the bar by measuring wafers in 3D in high resolutions and at high speeds. This enables chip manufacturers to control their production processes at the highest level, which is crucial for the manufacturing of chips for the new generation of smartphones, tablets and laptops.

Nearfield Instruments expects to deliver the first systems in the course of 2020. This brings a TNO-developed technology to the market and strengthens the position of the Netherlands in the world as a developer and supplier of high-tech systems.

More information?

Get inspired

Devices for detecting and measuring small particles

Metrology and inspection concepts