Innovation lab geothermal energy open for entrepreneurs

Geothermal energy has an important role to play in the energy transition, alongside other sustainable sources such as solar energy, wind and biomass. In time, heat from the subsurface can provide a quarter of the heat demand from homes, offices and industry.

In the Rijswijk Centre for Sustainable Geo-energy (RCSG) TNO is working with companies and universities to develop, test and validate new well designs and sensor technology as well as drilling techniques and materials to accelerate the development of geothermal energy.

At the moment in the Netherlands some twenty installations, mainly found in the greenhouse horticulture sector, produce about five petajoules (PJ) of geothermal heat per year. The aim is to increase this tenfold to 50 PJ in 2030 and, rising to 200 PJ in 2050. In total, geothermal energy will be generated from more than seven hundred sites. However, this will also require overcoming technical challenges that currently impede the profitable production of geothermal heat.

State-of-the-art facilities

In the former Shell lab, which TNO transformed into the RCSG with the support of the Ministry of Economic Affairs and Climate Policy, Energie Beheer Nederland, the province of Zuid-Holland and the municipality of Rijswijk, new technologies and production methods can be tested 'full scale' and 'full size'. All facilities are state-of-the-art. An extra-high building standing on heavy foundations contains installations that cover the entire spectrum of subsurface drilling. A drilling installation above an almost 400 metre deep research pit, hydraulic presses of 300 and 400 tonnes, pressure vessels up to 1,000 bar, 3 flow loops, a hydrostatic drilling installation and a piping system and pumps in the building that are connected to every installation.

Testing in real conditions

For companies in the sector and for the manufacturing industry that supplies components, testing new products, materials and techniques for subsurface application is a costly affair. Thanks to the advanced lab, they do not have to invest in an expensive test environment themselves. Almost all underground conditions can be mimicked with the real dimensions to determine how products, materials and components behave under high pressure or at extreme temperatures at depths of kilometres. This makes the lab unique in Europe.

Open innovation with companies and universities

TNO cooperates with companies in an open innovation model. Consortia are formed around the various research programmes of companies active in geothermal energy, heat storage, salt extraction, mechanical engineering, suppliers of components and materials. In addition, there is close cooperation with knowledge partners TU Delft and Utrecht University. The emphasis is on reducing costs and boosting safety. The projects are diverse and are organised programmatically to facilitate knowledge sharing in domains to accelerate innovation while safeguarding the commercial interests of the partners.

Some examples

TNO is working with Huisman GEO, energy company ENGIE and EBN on a new drilling technique that can make it profitable to produce geothermal heat from thin layers. This involves so-called multilateral drilling, known from the oil and gas sector, in which the drill bit branches out in three directions. The technique has yet to be made suitable for the production of geothermal energy. If successful, it could in principle double the yield. Trials are planned in a 2.5-kilometre-deep earth layer near Zwolle. Prior to this, the technique will be tested in the lab in Rijswijk to a depth of 400 metres.

With an international consortium, a Dutch Shell generated start-up will begin a test programme with an innovative, horizontal drilling technique, which is very suitable for the Dutch subsurface and should significantly increase the yield.

Casing materials are subject to corrosion and degradation but at depths of kilometres it is difficult to determine the condition of the well construction. TNO is working with companies such as Huisman and universities, on smart casing, new materials and integrated sensors, similar to modern sensor technology in cars. These technologies make it possible to reduce maintenance costs.

TNO is investigating with operators how natural subsurface materials such as clay and salt can be used for sealing for sustainable safety and circular well technology.

A reduction of flow resistance in pipelines will allow the installation of smaller pipe diameters, smaller pumps, geothermal well and other system components. This will reduce the costs of materials and costs of excavating and limit nuisance in the in the residence environment for geothermal district heat.

Get inspired

Open doors to Dutch subsurface research labs and data

GEMINI: intelligent decision support system for geothermal assets

Consortium with TNO searches for Stone Age remains at the bottom of the North Sea

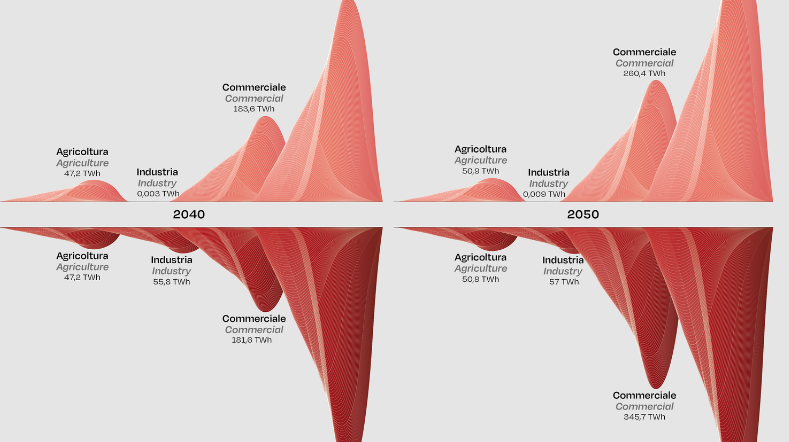

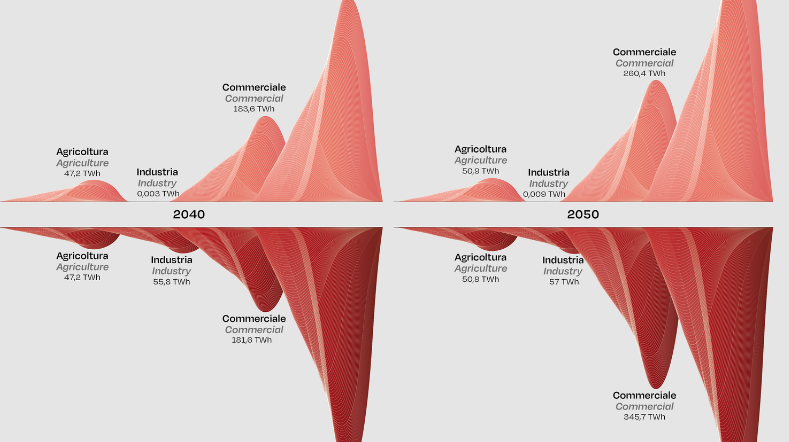

TNO studies on geothermal energy potential find their way to art gallery in Turin

Supporting municipalities to achieve heat transition