Systemic impact assessment of plastics value chains

We are committed to accelerating the transition to circular & sustainable plastics – envisioning a circular economy in 2050 that reuses and recycles all materials with minimal carbon dioxide emissions. One path towards realising that vision is developing systemic impact assessment methodologies and tools to help redesign the plastics value chains from the current linear systems to the ‘Plastics value chain of the future’.

Our work

To deliver on our commitments, we work closely with industry and government:

- by establishing quantitative environmental and economic indicators

- developing disruptive technical solutions

- building predictive climate and environmental models.

3 key elements of impact assessments

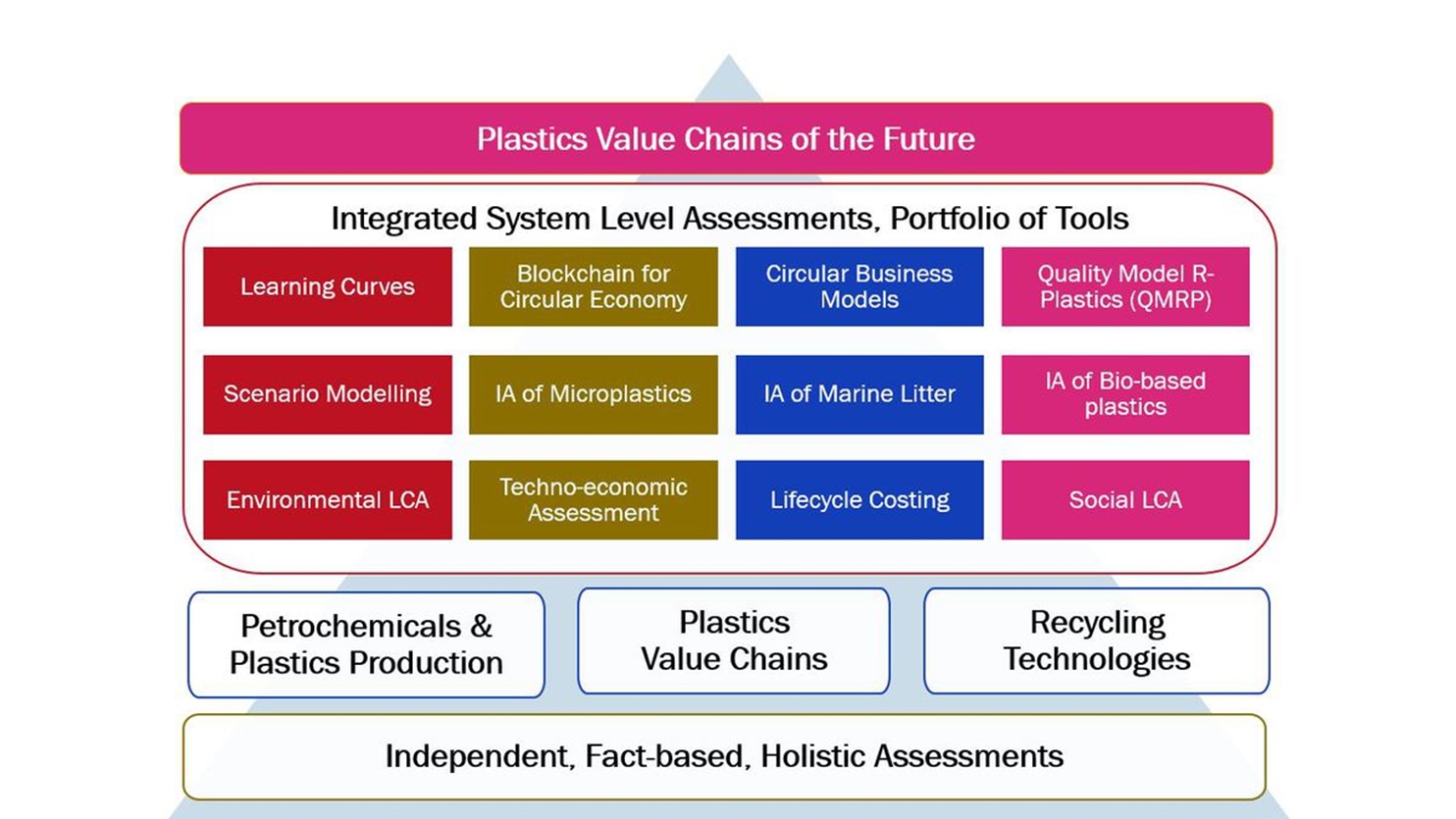

At TNO, we address critical issues related to plastics value chains through a systemic impact assessment approach. Figure 1 shows our approach to performing such impact assessments, which is made up of three core elements:

The pyramid foundation, the first core element, uses independent, fact-based and holistic assessments that form the base values of our impact assessments.

The second core element, value chain knowledge and expertise, consists of three main pillars in order to perform holistic assessments:

- existing and novel petrochemicals and plastics production technologies;

- plastics value chains;

- recycling technologies.

The third core element is the integrated system level assessments and platform-based approach. This approach allows us to examine and solve problems holistically by combining assessment tools such as:

- LCA

- LCC

- techno-economic assessments

- scenario modelling

- quality model for recycled plastics

- circular business models

- learning curves

Impact assessment of novel technologies

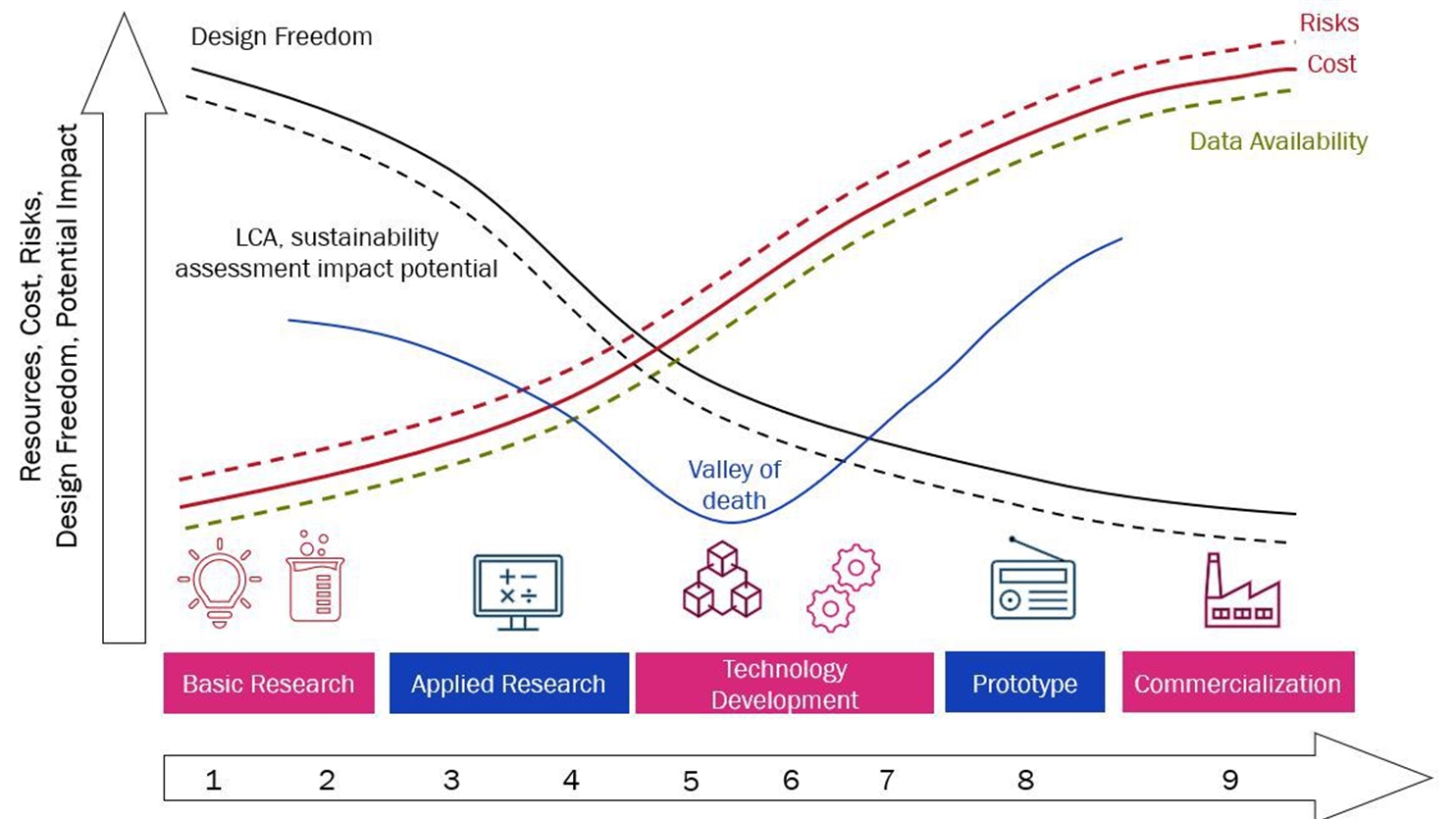

Evaluating the economic and sustainability performance of novel technologies is always challenging due to the many unknowns, such as missing technical and non-technical data (see Figure 2). But doing so as early as possible remains essential, as such assessments offer design freedom for technology selection and solution pathways to maximise the sustainability performance. They are critical to minimising so-called “valley of death” situations and business risks for technologies in the development cycle. Early-stage sustainability assessments also reduce costs and save time for technology development and commercialisation.

TNO, through its exhaustive expertise and experience in lifecycle assessment and techno-economic assessment, helps companies, value chain partners, associations, investment funds, and policy makers to make informed decisions on early-stage technologies. We provide deep insights throughout the research and development cycle by identifying environmental hotspots, technology assessment, evaluation of data gaps, as well as trade-offs with individual lifecycle stages, unit processes & impact categories, and substances of concern. Using screening assessments, we guide the design of each process step in a sustainable direction and towards high circularity performance.

Solving real-world problems

The team specialising in our systemic impact assessment plastics value chains is dedicated to solving real-world problems associated with circularity and decarbonising plastics. An example is our quality model for recycled plastics, which helps recyclers and product designers evaluate the quality of recycled plastics for their intended application. Furthermore, we look at ways to harmonise and simplify LCA methodologies for specific applications, such as battery electric vehicles. Through holistic techno-economic assessments, the team provides guidance on optimising the capital and operational costs of various recycling technologies.

More than a Circularity Impact Assessment

We employ an integrated approach to sustainability and circularity by evaluating lifecycle assessments, lifecycle costing, and circularity assessments. Evaluating only the circularity impact assessment of a product often isn’t enough to deliver optimum results. In projects such as CIMPA, for example, we combine the Material Circularity Indicator (MCI)1 with LCA and LCC to evaluate the sustainability impact of multi-layer packaging films.

Get inspired

Time setters: Safely recycling dirty food packaging

New facility to develop circular plastics on an industrial scale

Microplastics and packaging: reduction is achievable

Upwash technology: Improve quality of plastic waste

From #plasticfree to future-proof plastics