Platooning is positive for traffic, the environment and the wallet

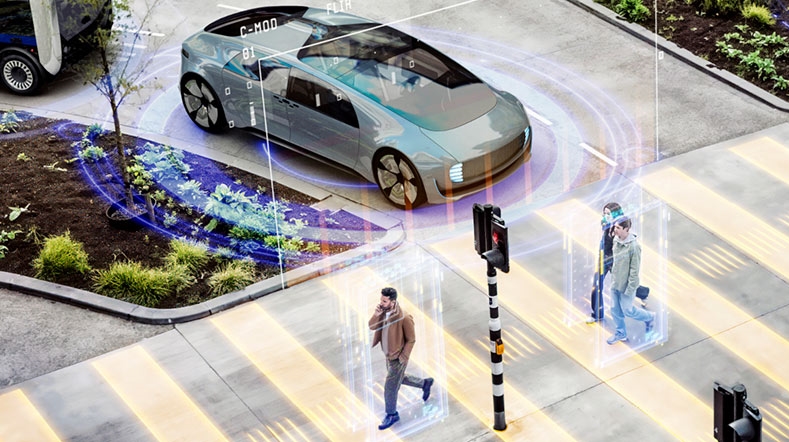

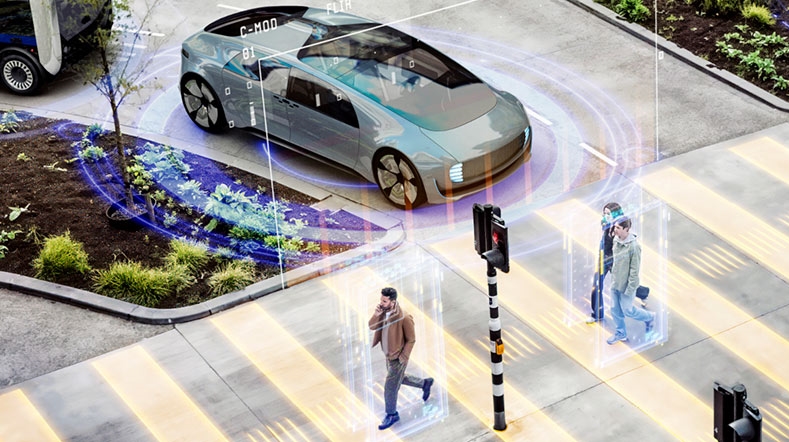

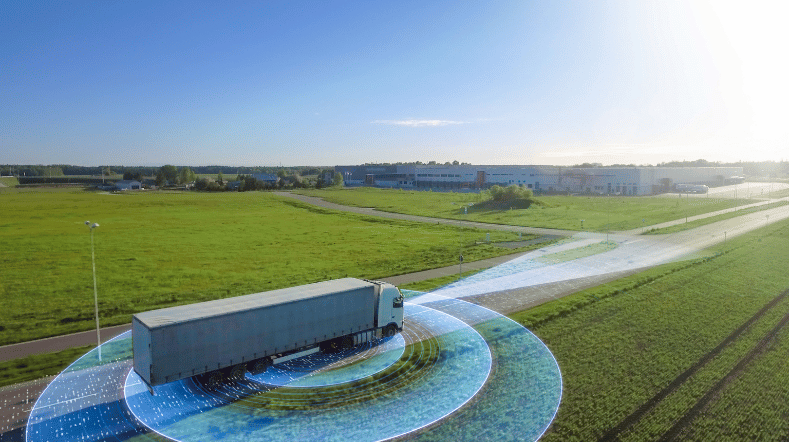

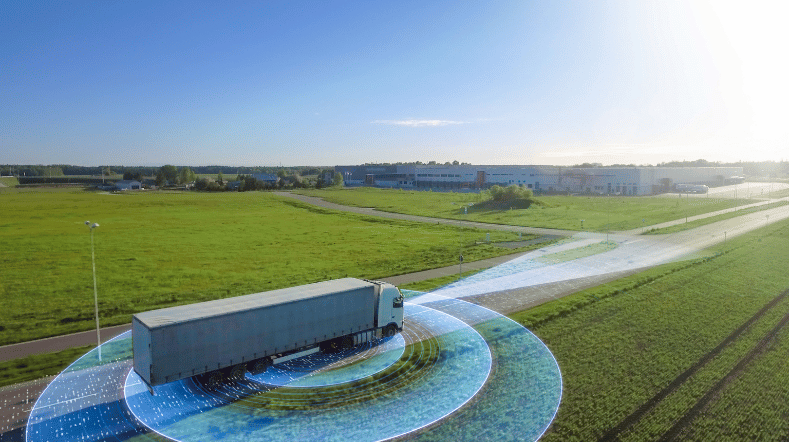

The Netherlands is a global leader in the development of truck platooning: small convoys of trucks that drive automatically. One or two trucks follow the actions of the first driver, at a distance of 0.3 seconds from the vehicle ahead: accelerating, steering, braking. These actions are automated by the use of vehicle mounted sensors - such as radar and camera - and wireless communication.

The advantages of platooning are fuel savings, lower CO2 emissions, improved road safety and better traffic flow. In a few years’ time, market introduction will be possible.

TNO gives platooning a kick-start

TNO aims system innovation at platooning, from vehicle level to system level, for multiple manufacturers and types of vehicles, and taking other traffic into account. The primary focus is on trucks; the secondary focus is on passenger transport (passenger cars and buses) and unmanned automated guided vehicles (AGVs). TNO wants to be able to integrate platooning and, to this end, it is undertaking the following initiatives:

- Achieving legal and technical acceptance for implementation

- Expansion of the operational area from motorway to distribution centres

- Increasing the level of automation and interaction with other traffic

- Towards fully automated logistics and passenger transport

TNO Truck Platooning explained

Watch our video and learn more about Truck Platooning.

Platooning for passenger cars? That is possible!

Truck Platooning is - in view of the advantages of its use - the springboard to platooning for passenger cars. Think of platoons of passenger cars, removal companies and driverless vehicles. Ask TNO about the possibilities.

Why TNO?

- TNO has more than 10 years of experience in developing, implementing and testing platooning technology with different types of vehicles on public roads.

- TNO has integral knowledge of the combination of embedded technology (vehicle control and environment monitoring), V2V and V2X communication technology, interoperability, safety and traffic system analysis.

- In the field of self-driving vehicles TNO has all the technologies, development and validation methods up to and including knowledge of legislation and human behaviour.

- TNO is independent and has an international network of manufacturers, suppliers, authorities, insurers and logistics companies.

This is what TNO can offer various parties

We advise and support vehicle manufacturers, their suppliers, logistics providers and the authorities. TNO also serves other stakeholders, such as road authorities and representatives of end users, by providing insight into the technology through demonstrations on public roads, simulation studies, technology assessment and pilot studies.

Advantages for manufacturers, OEMS

- Rapid build-up of knowledge and expertise in the field of platooning technology (transfer of knowledge and application to industry platforms)

- Accelerated time to market

- Independent assessment of vehicle technology

- Faster and more cost-efficient development of new automation functions to achieve level 4 automated driving faster.

Advantages for logistics providers, ports

- Increasing efficiency and safety

- Technology assessment and demonstration

Advantages for authorities

- Platooning contributes to safe traffic, lower CO2 and reduced traffic congestion.

- Accelerating the use of scientific knowledge in practice by TNO’s programmes

- Rapid increase of knowledge and expertise in the field of platooning technology

- Shortening the time to market of the technology

Whitepaper on truck platooning

Read the whitepaper 'Truck platooning: driving the future of transportation'.

Want to know more?

Would you like more information about what TNO can do for you in the field of platooning? Or are you looking to collaborate to make platooning widely available? Then please contact us.

Get inspired

Safe automated driving

Automated driving: the state of play in 5 key developments

Scenario-based validation of ALKS key step towards automated driving

Will we still be driving ourselves in 2030?

Integrated Vehicle Safety and Smart Vehicles